- Gas Storage Level Prompts Injection Guessing Game

- The Oil Industry’s Era of Austerity – Part Two

- Here Come The Offshore Wind Turbines – In Theory At Least

- Clothing Quality Article Morphs Into Environmental Concern

- UN IPCC Report Revives Fears Of Malthusian Future

- IMF’s Global Economic Outlook Hurts Energy Prospects

Musings From the Oil Patch

April 15, 2014

Allen Brooks

Managing Director

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

Gas Storage Level Prompts Injection Guessing Game (Top)

The bitter cold winter of 2013-14 has driven the level of natural gas in storage in the U.S. to the lowest level in a decade. As of the week ending April 4, 2014, there was 826 billion cubic feet (Bcf) of natural gas in storage following a minimal injection of 4 Bcf during the week. The winter withdrawal season officially runs from November 1st to March 31st, with the injection season extending from April 1st to October 31st. Obviously, the calendar doesn’t always accommodate those exact dates, but essentially the injection season lasts for the 32 weeks from the end of March through the end of October.

The guessing game has started about whether the petroleum industry will be able to rebuild natural gas storage volumes to a level that will make consumers and gas industry executives comfortable that there will be sufficient supply for next winter. Of course, the overriding issue in determining the level of comfort is whether the industry can rebuild storage to a level that even another severe winter such as we just experienced will not obliterate the gas inventory. The threshold for that comfort level appears to be three trillion cubic feet (Tcf) of gas in storage. What that means is that during the injection season, the gas industry will need to add approximately 2.2 Tcf of new supply to what is currently in place (826 Bcf).

The question confronting the industry is how much natural gas can be injected into the nation’s storage caverns this summer. While it would seem that the answer to this question is a straight forward mathematical calculation, the reality is that numerous factors such the summer heat, growth (or contraction) in gas production, how much gas-oriented drilling takes place and how many drilled-but-uncompleted dry gas wells are available for completion will determine the outcome. One of the most critical variables in this

Exhibit 1. Natural Gas Storage Level At Historical Low

Source: EIA

equation is what the supply/demand factors for gas production will do to gas prices. If they rise, it will encourage more gas-oriented drilling, but at the same time, higher prices will hurt gas demand. On the other hand, lower gas prices will discourage additional drilling, while stimulating consumption. Looking to the past may provide us an idea of the likelihood of the industry rebuilding depleted gas storage to an adequate level before next winter.

Most people are familiar with the sorry state of our gas storage situation as shown in the April 4th chart portraying the history of gas storage levels over the past two years. (Exhibit 1.) The graph, published by the Energy Information Administration (EIA) shows the level of weekly storage volumes during the past two-year time frame along with the maximum and minimum storage volumes calculated over the past five years. Included in the five-year history is a solid dark line showing the average five-year storage amount. Almost from the start of the winter withdrawal season, the gas storage was at the five-year minimum level before dropping dramatically when the polar vortex enveloped the nation at the start of January, which was followed by continued bouts of Arctic cold air and winter storms for the balance of the season. Even as recently as two weeks ago, the New England region was hit with cold and icy winter-like weather.

Now that the gas industry is in a deep hole, can it extricate itself? During the past 20 years, there have only been three other times when the end of the winter found gas storage at a lower level than now. That happened in 1996, 2001 and 2003. There were two other years when gas storage fell below one Tcf – in 1994 and 1997, however, these previous low levels were above where inventories currently sit. While gas storage levels now are quite low, we have nearly half a dozen examples of how the market responded to the challenge of rebuilding storage.

Exhibit 2 shows the starting and ending storage volumes for each year since 1994. The shape of the graph presents an interesting visual image reflecting the impact of the warm weather period we have recently experienced, but more importantly it also shows the impact of the gas shale revolution. Until this year, the last time the industry began the injection season with storage volumes below 1,000 Bcf was in 2003. The period from 1994 through 2003 reflected an industry period in which the gas business struggled with static demand, but falling production. Beginning in 2005, the shale revolution emerged as a force in the gas industry, partially in response to sharply higher gas prices, but primarily due to the technological advances that enabled production of natural gas from shale. As a result of the weather, supply growth and struggling gas demand, every summer injection season began with storage volumes in excess of 1,500 Bcf, except for 2008. Also note that since 2009, the industry never ended an injection season with less than 3,500 Bcf in storage. This season sees the industry at a modern low and facing a mountain to climb if it is to return to 3,000 Bcf of gas storage. From the current 826 Bcf of storage, this means an injection of nearly 2,200 Bcf of gas this spring and summer.

Exhibit 2. 2014 Presents Injection Volume Challenge

Source: EIA, PPHB

Natural gas production has been growing at a healthy pace the past few years due to increased shale output. As shown in Exhibit 2, gas consumption began to grow in recent years as production has also climbed. The result has been a reduction in the volume of natural gas imported from Canada to meet demand. At the same time, the U.S. has stepped up its natural gas exports to Canada’s eastern provinces and Mexico, but this has not hurt gas injection volumes.

Exhibit 3. Production And Consumption Growing

Source: EIA, PPHB

A driver for the recent increase in natural gas consumption has been a dramatic increase in the amount going into the power sector. Since 1997, when the power sector data started being reported separately, there has been a doubling in the annual volume of natural gas consumed by power plants. That increase has been due to increased regulatory pressure on coal-fired power plants and the availability of cheap natural gas. An outcome of this power generation market share gain for natural gas has been a corresponding drop in coal prices. The challenge facing natural gas is the low price of coal that is drawing demand away from gas.

Exhibit 4. Cheap Gas Powers Market Growth

Source: EIA, PPHB

Will the gas industry be able to deliver volumes this summer to restore storage to three Tcf or more? When we look at the history of the average weekly storage injection since 1994, we see that the industry has been able to consistently deliver healthy injections. If we look at annual injections since the 2008 financial crisis, with the exception of 2012, when weekly injections only averaged in the mid 40’s Bcf, the rate has consistently been in the upper 60’s Bcf. To reach the three Tcf storage threshold, the industry needs to average roughly 70 Bcf a week, which is certainly a realistic possibility.

Exhibit 5. Gas Injections Consistent Since 2008

Source: EIA, PPHB

There are three reasons why we believe the gas industry can rebuild storage to the comfort threshold by November 1st. First, gas production continues growing despite the energy industry’s focus on tight oil and liquids-rich gas plays. Virtually everyone in the business has been surprised by the industry’s ability to keep gas output growing while drilling fewer gas wells. That condition reflects the associated gas output from tight oil wells and the residual gas volumes from the liquids-rich plays. We see nothing on the horizon suggesting any change in this relationship. A possible negative consideration may be the impact of wet grounds, especially in the shale areas, which could limit the movement of equipment and the hooking up of producing wells. While pipeline construction would be hampered, the growth in pad drilling in shale basins mitigates the impact on drilling rig movements.

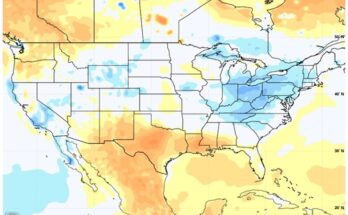

Exhibit 6. Could Soil Moisture Impact Gas Drilling?

Source: WeatherBank

Secondly, as natural gas prices have climbed into the mid to upper $4 per thousand cubic feet range, cheaper coal has been able to reclaim some of the power generation market it has lost to gas. If gas prices remain high, this will encourage more gas-oriented drilling that should produce additional supply, but the higher prices will also trim gas demand in the power generation sector.

Exhibit 7. Cool Spring Weather Predicted

Source: Browning Newsletter

The third, and possibly the most important consideration is this summer’s weather. Will the heat match the record cold of the recent winter, or will the cool spring transition into a cool summer? We have seen comments from some weather services suggesting that this summer should have normal temperatures. The Browning Newsletter is calling for this summer to be cooler than the historical average, which means electricity demand may not be as high as in recent years, reducing demand for natural gas. If that happens then there will be increased gas supply available for injection into storage making the 70 Bcf a week target a much more likely scenario.

Exhibit 8. Will Cool Summer Prevail?

Source: Browning Newsletter

One of the more interesting comments in the Browning Newsletter was a bullet point accompanying a chart showing the global factors shaping the spring and summer weather. Point nine stated: “As the cold Arctic air escapes south, Arctic temperatures are returning to normal for this decade.” That comment suggests we are not likely to experience during the next few years any of the polar vortex-type weather conditions seen twice this past winter. That said, we should be mindful of the possibility of cold winter weather during the next few winters due to increased volcanic activity earlier this year that has put particles into the atmosphere that subsequently will block out sunlight and drive temperatures lower. As the Browning Newsletter points out, we are just now coming out from under the influence of volcanic emissions from 2011.

Exhibit 9. Conditions For Cooling May Extend Long-Term

Source: Browning Newsletter

Probably the most pressing question for the natural gas market in addressing storage injection rates is the impact on gas prices. In Exhibit 10, we plotted the futures gas price at both the start and end of the injection season. It is interesting that in the years when the injection season started with storage volumes at low levels, there was virtually no difference in beginning and ending gas futures prices. In fact, in 2001, the ending price was lower than the starting price! The dramatic change in natural gas prices came via the financial crisis of 2008.

Exhibit 10. Mixed Gas Price Reaction To Injection Needs

Source: EIA, PPHB

As seen in Exhibit 10, the big price reactions over the course of the injection season came in 2004 and 2005 when storage volumes started at 1,014 Bcf and 1,239 Bcf, respectively. The ending storage volumes for those two years were 3,293 Bcf and 3,168 Bcf, respectively, showing that the industry was able to inject nearly 2,300 Bcf and a little over 1,900 Bcf in those years. Those are healthy injection seasons.

While many analysts are wondering whether the gas industry will be able to rebuild storage volumes to prevent a supply crunch next winter, it would appear from an analysis of the current state of the industry and its history that this mission can be achieved. One result of this scenario is that gas prices will likely remain higher than people had previously assumed before the bitter cold winter decimated storage volumes. The higher gas prices go in the future, however, the more incentive there will be for increased gas-focused drilling and for cheap coal to recapture power generation market share at the expense of gas. Those dynamics could be critical when coupled with the possibility of a cooler summer. As a result, we could see an erosion in gas prices over the summer, just as everyone begins to accept higher prices as the new normal.

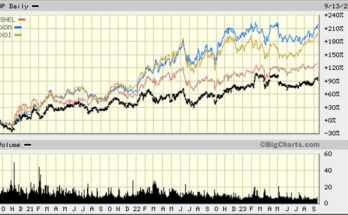

The Oil Industry’s Era of Austerity – Part Two (Top)

As the major oil companies struggle with how best to boost their profitability in an era of rising oilfield costs, business models are being adjusted. The changes are a reflection of managements’ attempts to change the culture of their organizations. The most popular theme is to split a company’s business into separate units with different investment and operational characterizations. For example, a popular way to split an integrated oil company is to put the most capital-intensive businesses – refining, petrochemicals, transportation and marketing – all in one basket, while the exploration and development business sits in another. That approach was popularized a few years ago by Marathon Oil (MRO-NYSE) and ConocoPhillips (COP-NYSE). The strategy was recently criticized by Archie Dunham, former CEO of Conoco at the time of its merger with Phillips Petroleum. His reasoning for disagreeing with this structure was that the capital-intensive businesses generated large cash flows that helped fund the capital needs of the E&P business.

Lately, a new business model is being promoted. That model involves splitting off the shale resource portion of a company’s E&P operations into a separate unit in an attempt to mimic the structure, and presumably the operations, and hopefully the profitability, of an independent oil and gas company. The thinking behind this move is that the philosophy driving successful shale exploiters is quite different from that needed to exploit conventional oil and gas plays. For the major international integrated oil companies, this rationale may prove successful. What it takes to be successful in hunting for and developing elephant-type fields in deepwater and remote regions of the world is considerably different from success in the domestic shale basins where the emphasis is on finding the optimal drilling and completion techniques and then repeating them over and over and over again with a goal of driving costs down. The strategy is the equivalent of buying bespoke goods versus mass produced items.

The two major oil companies who have recently embraced this new business model include Royal Dutch Shell (RDS.A-NYSE) and BP Ltd. (BP-NYSE). It remains to be seen how long it takes for each company to establish these new business units. In the back of the minds of many observers is the question of whether these moves are initial steps toward completely severing ties, i.e., selling or spinning off the entities. Our question with this business model structure is whether a corporate culture can be redesigned to achieve a different goal?

Exxon Mobil Corp. (XOM-NYSE) attempted a culture shift when it purchased XTO Energy a few years ago. At the time the deal was announced, observers questioned how ExxonMobil would be able to retain the key XTO managers who were used to a high degree of freedom to experiment, which is often found in smaller, independent oil and gas companies, as opposed to the monolithic and highly structured enterprise of its new parent. ExxonMobil’s approach was to retain XTO’s offices and management and to move ExxonMobil’s shale staff in. So far this shale investment has yet to financially pay off as envisioned by ExxonMobil’s management. Fortunately, the company has avoided the embarrassment of having to write down the value of its shale investment despite continued low natural gas prices and CEO Rex Tillerson’s lament in 2012 that the company was “losing its shirt” in shale gas. The fact ExxonMobil has not taken an asset impairment charge as many of its peers have caused the Securities and Exchange Commission (SEC) to question the company about how it was able to avoid that fate.

According to a Wall Street Journal blog in early February, the company responded to the SEC inquiry stating that placing a value on wells that pump oil and gas for decades requires considering many factors, including future events. For example, the company has had approved a liquefied natural gas (LNG) export terminal that once in operation could lift the value of its domestic natural gas resources above the current price and, importantly, future prices as suggested by quotations in the futures market. Whether that reflects true conviction or significant leverage over the company’s auditors is difficult to know.

Another way in which producers are addressing their reduced profitability is to attack their cost structures. Royal Dutch Shell says it plans to begin using cheaper Chinese oilfield equipment in order to lower operating costs. This would be a significant cultural adjustment as oil company purchasing departments are mandated to find the lowest cost equipment as long as it meets industry and company specifications. If the company has not been using Chinese equipment, the question is why?

This Chinese equipment strategy reminds us of Shell’s “Drilling in the Nineties” program designed to cut E&P costs. The approach was that oilfield service companies needed to bundle all its drilling and completion offerings into a single package and then price the entire package cheaply. The problem was that Shell’s drilling engineers, responsible for the success of wells and fields, wanted to make sure they could get the best equipment and services to ensure their success. If the service company that won the contract only had, for example, the number three ranked drilling fluids needed, the Shell engineer would arrange to purchase the number one product from a different service provider.

We will never forget a discussion we witnessed dealing with Shell’s program that occurred at an early 1990s annual meeting of the International Association of Contract Drillers (IADC). At the end of the back and forth among the drillers about the pros and cons of Shell’s program, one elderly gentleman, the president of a long-time West Texas contract driller, stood up and said, he didn’t understand what all the fuss was about since this approach had been going on for decades – it was called turnkey drilling! Everyone laughed and as if a light bulb went on, the discussion ended. Drilling in the Nineties eventually disappeared only to be replaced by “Best in Class” in which the producer or driller selected the best vendor in each supply category.

The battle over price versus quality of drilling and completion equipment and services has always gone on and the winner depends on the relative tightness of the market. The tighter the market, the better it is for service companies. Likewise, the looser the market, the better it is for producers. The common thread of all the various drilling and service contracting initiatives tried in the industry was how they fostered consolidation within the oilfield service industry. That may be the same outcome this time, too.

Here Come The Offshore Wind Turbines – In Theory At Least (Top)

In Rhode Island, the subcommittee of the Coastal Resource Management Council (CRMC) approved the plans for the five or six wind turbine demonstration project offshore Block Island. The subcommittee will be recommending to the CRMC that it grant final approval for the project, which should allow the sponsors to begin securing financing and hopefully begin construction in 2015. On the other hand, the Cape Wind project in Nantucket Sound off the coast of Massachusetts received another blow when a federal judge ruled that the U.S. Fish and Wildlife Services and the National Marine Fisheries Service violated environmental laws by failing to adequately consider the impact of the seasonal shutdown period for the 130 wind turbine project on migratory birds and the endangered right whales. Cape Wind has not agreed to a seasonal shutdown arguing that it would destroy the economics of the project. Resolution of these issues likely mean the project will not be cleared to proceed until later this year or maybe even early next.

Exhibit 11. Cape Wind Located In Shallow Water

Source: Boston.com

Offshore wind, and these two projects, will be a beneficiary of the decision by Congress to resuscitate the renewable fuel tax subsidies that died at year-end. On April 4th, legislators agreed to restore some 50 tax subsidies, including wind’s, that ended last year and are now awaiting a legislative bill they are sure will pass both houses of Congress to attach this rider. The legislators’ decision to revive these subsidies confirms that Washington’s discussion about overhauling our tax structure was little more than political posturing.

Wind energy has complained about the impact on its industry from the expiration of the tax subsidy that is worth $23 per megawatt hour to turbine owners. Wind proponents claim that without that subsidy, which is what makes wind power competitive with other fuels, primarily gas and coal, the industry may die. They point to the ability of the gas industry to form master limited partnerships to reduce their cost of delivering gas to customers and undercutting wind.

According to Bloomberg New Energy Finance, the cost to install a megawatt of power worldwide is about $84 for both wind and natural gas, excluding subsidies. That is three percent higher than what a coal-fired power plant produces a megawatt hour of power and about half the cost from a nuclear power plant. The ability of utilities to scale up and down the output from gas-fired generators has enabled them to accept more wind and solar power that are highly variable. One analyst described the symbiotic relationship of wind and natural gas as “frenemies with benefits.”

Renewable fuel subsidies would be a critical consideration should the country adopt the recommendation of professors from Stanford University and the University of Delaware regarding building huge offshore wind turbine arrays as a mechanism for protecting the U.S. coast from hurricane strikes.

A new paper published online at Nature Climate Change, a peer-reviewed journal, suggests that based on an advanced climate-weather computer model, large offshore turbine arrays may diminish peak near-surface hurricane wind speeds by 56-92 miles per hour and their associated storm surges by 6-79%. The paper also claims that the net cost of the turbine arrays, which is defined as the capital cost for construction and their operating cost minus the income from the sale of electricity generated by the turbines and the benefit from the health, climate and hurricane damage avoidance, is less than the estimated net cost of fossil fuel electricity generation in the region and less than the net cost of sea walls constructed solely to avoid storm surge damage. These are interesting and dramatic claims, but, like so many of these studies, are based solely on computer simulations and numerous assumptions.

In fact, when asked about the idea, Accuweather.com meteorologist Dan Kottlowski was quoted saying, “I can’t dispute that it sounds like a really good idea.” His problem was that he questioned the assumptions used in the model regarding weakening hurricanes since there is ongoing research to try to understand hurricane intensity. “We don’t quite understand all there is to understand in the science as to why a hurricane weakens or intensifies,” said Mr. Kottlowski.

The research paper conducted simulations of the impact of wind turbine arrays of various sizes on the hurricane measurements from three storms – Katrina in 2005, Isaac in 2010 and Sandy in 2012. To decrease the intensity of the hurricanes the industry must construct thousands of offshore turbines. According to scenarios used in modeling the turbines’ impact on Hurricane Katrina, the size of the arrays is directly proportional to their benefit. Mark Jacobson of Stanford, one of the co-authors of the study said, “We used 78,000 turbines and saw an 80-percent reduction in storm surge. You would see approximately a 56-percent reduction with 40,000, and with 20,000 maybe a 20- to 30-percent reduction.” One of the key points of this study is that the electricity generated by the turbines would pay for their cost.

A quick calculation of the cost of turbines makes us wonder about the argument. Based on the latest cost estimate for the Cape Wind project of 130 turbines in Nantucket Sound of $200 million, the cost per turbine to buy and install it would be roughly $1.5 million. The mean water depth of Nantucket Sound is nine meters, or 28.8 feet. If we use this wind turbine installed-cost estimate for the 78,000 turbines proposed for offshore New Orleans, the cost would be $120 billion. The cost of installation and the power cables, etc. would be much greater than for Cape Wind as the water is much deeper and the number of turbines significantly greater.

The paper’s authors comment on economics in one example. They suggest that if wind turbines were used merely for hurricane avoidance, an array covering 32 kilometers (19.8 miles) of linear coastline in front of New York City would cost ~$210 billion with no payback from electricity generation. The cost of the proposed sea wall to protect New York City is estimated at between $10 billion and $29 billion. The authors claim that this turbine array would cost less than that of the sea wall if the turbines were producing electricity all year in addition to providing hurricane protection.

In the interview with Mr. Jacobson, the suggestion was made that this model is probably not for private companies but certainly it is something a government – state or federal – could justify. Mr. Kottlowski pointed to the operational success of offshore wind turbines in the North Sea, which he said is one of the stormiest places on Earth. The problem with that statement is that most of the violent storms are in the area between the UK, especially off Scotland, and Norway, not the shallow-water region offshore Germany and Denmark. Mr. Kottlowski further commented, “I’m a skeptic as far as maintenance, but those turbines in the North Sea are working and they’re proving they generate electricity. Building an array of 78,000 turbines would be quite an engineering feat.” Yes, especially since the water depth offshore New York City is much deeper than offshore Germany and Denmark and certainly much deeper than Nantucket Sound.

Another aspect of those European offshore turbines is that they often are paid to be idle whenever the utilities do not need the power. According to data from the UK’s National Grid (NGG-NYSE), last year it paid a record £30 ($49.8) million to wind farm operators when the utility could not take the electricity generated by the wind turbines and they have to shut down. These wind farms are being built to help the utilities meet their mandate that by 2020 Britain’s energy consumption from renewables needs to reach 15%. But as John Constable of the Renewable Energy Foundation, which compiled the payment record, put it, “The scale and pricing of wind power constraints in 2013 clearly shows that the full system cost of wind power is much higher than government is willing to admit. Unfortunately, there are no cheap solutions, and, ironically, paying wind farms not to produce energy may actually be cheaper than building more grid. At some point government will have to face the fact that wind power is simply too expensive to provide more than a minor share of UK electricity.”

At the present time, the UK has 4,000 onshore and 1,000 offshore wind turbines installed and operating. The shut-off subsidy payments directly impact customer electric bills. The political pressure from the combination of visual pollution and escalating power bills due to renewable fuel subsides has reached the level that the Conservative Party in Britain has announced it plans to campaign next year on a platform calling for no more onshore turbines after 2020, but instead it will shift its focus to more offshore wind farms and solar installations. The objective of this shift is in response to the concerns of citizens. It is also hoped that large offshore wind farms will be easier to integrate into the UK power grid and reduce the shutdown payments.

While the offshore represents 20% of the nation’s installed wind turbines, some offshore projects are only approved and are awaiting determination of their economic viability. The world’s largest offshore wind farm is Raheenleagh Wind Farm located off the coast of Ireland. It is currently operating at partial capacity. At full capacity, it will have 200 turbines, a total power rating of 520 megawatts and cost nearly $600 million to build, or an average of $3 million per turbine. In December, Scottish Power Renewables cancelled its plan to build the Argyll Array scheme off the coast of Tiree in the Inner Hebrides. This wind farm was designed for 300 turbines that could power up to a million homes. The decision to cancel the project was due to construction issues and that the project was not financially viable in the short term. The reported cost of this project was £5.4 ($8.97) billion, or nearly $30 million per turbine. Because the proposed location of the wind farm is on the most westerly island of the Inner Hebrides, an island of 30.25 square mile areal extent and 460 residents, its remoteness probably necessitates substantial infrastructure investment that inflates the per turbine cost to $30 million. The island is a tourist attraction for surfers and windsurfers because of its favorable winds.

We find it interesting that the world’s largest offshore wind farm has only 300 turbines. We are not aware of any wind farms having thousands of turbines, let alone tens of thousands. In the research paper, there are a number of scenarios presented where the authors attempt to demonstrate that by adding turbines they can minimize the intensity and storm surge from hurricanes. We looked at a couple of the scenarios, and attempted to determine what the forest of wind turbines will look like. One scenario was to place the turbines between Washington, D.C. and New York City to measure the reduction in Sandy’s strength. That is a distance of 316 miles. Based on the latest (December 2013) research on optimal spacing for offshore turbines, there should be 0.34 mile between the turbines and 0.54 miles separating the lines of turbines, which happens to be

Exhibit 12. Desolate Island Too Costly For Wind Farm

Source: Wikimedia Commons

the spacing adopted by Cape Wind. The latest thinking about turbine spacing says that they are more efficient if they are not lined up like soldiers in ranks, but rather staggered in each row as seats often are arranged in theaters to provide better sight-lines. The researchers’ computer model determined that 112,014 wind turbines were needed to be positioned off the New York to Washington, D.C. line. The spacing requirements dictate that the wind farm’s areal extent would be lines 316 miles long, each line containing 948 turbines. The width of the array would be parallel lines covering over 56 miles of sea surface. What havoc would that play with shipping?

What would have been gained had all these turbines been in place when Sandy developed? The computer model predicted that the 112,014 turbines would have dropped the simulated wind speeds by 80.8 miles per hour (mph) or 130 kilometers per hour (kph) and reduced the storm surge by 21%. Sandy’s peak sustained winds occurred when the storm was off the coast of Cuba at 115 mph (185 kph). By the time Sandy made U.S. landfall in New Jersey, Sandy’s sustained winds were only 80 mph (130 kph).

Another East Coast scenario involved extending the turbine array the entire length of the coast. The coast extends 2,069 miles, or a sufficient distance to include 6,207 turbines in a straight line. Since the computer model calls for 420,628 turbines, that means the width of the array will be 70 lines of turbines, or more than 35 miles wide. Based on the statistics above, the turbine array would have turned Sandy into a stiff breeze with little sea surge. However, what do you think the UN would say about this wind farm array disrupting the freedom of the seas, let alone the maritime industry and the U.S. Navy?

Once again, we see academics producing a nice, net energy analysis founded on assumptions about changes in hurricane intensity that meteorologists question. Moreover, the assumptions include the acceptance that all the offshore turbines will withstand an intense hurricane without damage and that they will generate electricity all year long to offset the cost of building the arrays. We truly wonder whether these professors ever considered what they were designing and whether it could be built, let alone whether it would be economic.

Clothing Quality Article Morphs Into Environmental Concern (Top)

A recent article in the Financial Times on the shoddy clothing we are buying today evolved into a discussion about energy and the environment. The article, entitled “High price we pay for shoddy clothing” by columnist Michael Skapinker, began by ruing the deterioration in the quality of the clothes we buy and wear. Mr. Skapinker talked about his experience with dress shirts after noticing recently that his were coming apart at the seams despite his historical weekly wear and washing pattern. In response, he said he had abandoned the “high street chains” and started buying his shirts from companies that incorporated Jermyn Street’s quality in their label. He found that these shirts also performed poorly – lasting only six to nine months with his weekly wash and wear routine. In response, he posed the question: Were clothes once more durable?

In seeking the answer to his question, Mr. Skapinker found that there has been no historic data collected on the subject. He learned that in the UK, according to a government report, two million tons of clothes are bought each year, while one million tons are discarded. The report stated that this “low-cost, short-lifetime” sector accounts for a fifth of the UK clothing market. The sector is heavily influenced by fashion stores, media coverage of celebrities and trendy social media. What he also found was that based on a survey last year for the Waste and Resources Action Program (WRAP), a non-profit advisor to governments and business in the UK, people own, on average, 26 items of clothing they haven’t worn in the past 12 months. But at least those items haven’t been discarded. A 2012 YouGov.com poll said that the leading reason why clothes were discarded was because they were damaged.

His question of whether better-made clothes was the solution to shoddy clothes for those not influenced by fashion trends shifted the discussion to the environmental cost of producing and maintaining wardrobes. There is an environmental cost to washing clothes in hot water and then tumble-drying them. WRAP also points out that discarding them also has an environmental cost since “natural fibers biodegrade in landfills and emit methane, a powerful greenhouse gas.” However, the biggest environmental cost comes from making the clothes in the first place. WRAP says the production phase – from producing the fibers to retailing the garments – accounts for over three-quarters of the carbon emissions and 90% of the water used during the clothing life-cycle. This environmental cost exceeds that from machine washing and drying them.

Since so many of our clothes are now made in poor countries, the large volume of water required during the production process can stress global water supplies where they can least afford it. An economic dilemma is that these poor countries rely on the world’s more prosperous countries to continue buying their output in order to keep providing jobs. But is that the best thing to do for the environment? A 2006 study in the UK by The Salvation Army Trading Company Limited (SATCOL), University College Northampton and Environmental Resources Management investigated whether the recycling of clothes, shoes and textiles actually results in a net energy benefit.

SATCOL looked at the energy footprint of its organization based on energy consumption data for one ton of recycled clothing in 2000/2001. The energy consumption was based on the energy needed to operate its internal transportation system for collecting and distributing donated items. That measure totaled 1,697 kilowatt-hours (kWh), which was a fraction of the 66,648 kWh of energy needed to create one ton of cotton garments from virgin materials. Garments made from polyester materials required nearly 50% more energy – 91,508 kWh.

The U.S. Energy Information Administration (EIA) lists the textile industry as the fifth largest contributor to CO2 emissions after primary metals, nonmetallic metal products, petroleum and chemicals. Textiles, including clothing, account for one ton of the 19.8 tons of total CO2 emissions generated by each person in the United States, based on 2006 data. The amount of greenhouse gas generated from textiles and clothing is influenced by what fiber the garments are made from. A study conducted by the Stockholm Environment Institute on behalf of the BioRegional Development Group shows that natural fibers, such as cotton, when grown organically create the least amount of carbon emissions throughout their life-cycles. Polyester, on the other hand, is much worse, and within the synthetic fiber universe, acrylic is 30% worse and nylon is an even poorer performer.

Exhibit 13. Organically Grown Natural Fiber Least Polluting

Source: Stockholm Environment Institute, PPHB

If environmentalists such as Mr. Skapinker have their way, the world will be shopping at Salvation Army and other thrift stores rather than in fashion shops and department stores, as recycled clothes are less polluting than newly manufactured ones. While this appears to be a good idea, recycled clothing has mostly been limited to young children who tend to outgrow their garments before they wear them out. So while minimalists will push us to shop for recycled garments, they may have better luck pushing for people to buy better quality clothes made from natural fibers and fewer of them as a way to contribute to an improved environment. We’re not sure what that does for the poorer nations of the world.

UN IPCC Report Revives Fears Of Malthusian Future (Top)

It would be hard not to know that the latest version of the UN’s Intergovernmental Panel on Climate Change (IPCC) report has been issued. Not only are the newspapers and magazines full of articles about the cataclysmic future for the planet given the relentless rise in global temperatures due to man’s burning of hydrocarbons, but the television media has decided this is the season for specials dramatizing the supposed linkage of climate change and weather disasters, a link the UN report actually rejects. It is almost like television producers believe they needed to revive former Vice President Al Gore’s 2006 documentary, “An Inconvenient Truth,” which popularized the idea that natural disasters were increasing in severity and were linked to global warming.

One of the themes found in the summary report prepared for government policymakers is how climate change will impact global food stocks – not well. The conclusions are based on a survey of 73,000 scientific papers about climate change and the linkage to the burning of fossil fuels. This year’s conclusion is a marked change from the 2007 report’s conclusion that yields for the world’s main grain crops – wheat, rice, maize and soybeans – would improve in temperate and cold climates but decline elsewhere due to increased global warming. Then, some people seized on the conclusion to suggest that a modest amount of warming would benefit the planet’s population, but the new report concludes otherwise. The IPCC position now is that while global warming will cause a decrease in topical region crop yields, the benefits from yield improvements in temperate zones will be less than previously thought. Increasingly, scientists are focusing on global warming’s impact on soil moisture and how that influences growing rates given that temperature spikes, if they occur at the wrong time, could damage crop yields.

According to the IPCC, wheat yields are falling at a rate of 2% a decade compared to what they would have been without global warming. Maize yields are down 1% a decade, while rice and soybeans yields are unchanged. The report suggests that over time this situation could worsen. About half the studies of likely grain yields over the next decade suggest they will fall, while the other half believes they will increase – hardly a convincing argument. Between 2020 and 2030, the forecasts are more negative with two-thirds predicting a fall as an increase.

Not surprisingly, by seizing on violent weather events – droughts, wildfires, tornadoes and floods – and the conclusion about falling crop yields, we are now seeing pundits predicting a Malthusian future for the global population. The most recent article was by New York Times economics columnist Eduardo Porter. His column was titled, “Old Forecast Of Famine May Yet Come True.” He points out how Thomas Malthus’ predicted that exponential population growth would condemn humanity to the edge of subsistence. He wrote some two hundred years ago, “The power of population is so superior to the power in the earth to produce subsistence for man that premature death must in some shape or other visit the human race.” That warning was buried by the fact the world’s population between 1820 and 2000 grew by 600%, while its economic output multiplied more than 50 times.

Now, with populations continuing to increase and food yields declining and projected to experience greater declines in the future, in the eyes of some, our fate is sealed. If you subscribe to that view, then take heed that you have about 15 years to prepare for the coming global food crisis. Will our government rally us to create 21st Century Victory Gardens? Maybe we should be brushing up on our agricultural skills, while figuring out where to locate our gardens. Then again, maybe we just bet on continued human ingenuity to overcome this problem.

IMF’s Global Economic Outlook Hurts Energy Prospects (Top)

On the eve of the annual meeting of the International Monetary Fund in Washington, D.C., the organization published its latest view of the health of the global economy. The bottom line is that it reduced its overall global growth projection for 2014 by 0.1 percentage point from the forecast the organization issued last October. The reduction was due to lowered growth estimates for Japan and a number of developing economies, coupled with continued sluggish growth in the U.S. and Europe.

Exhibit 14. IMF 2014 Economic Outlook Reduced Marginally

Source: The Wall Street Journal

The good news in the forecast was that the IMF has drastically reduced its view for a near-term recession. The IMF now gives a 0.1% probability for a global recession in 2014, down from the 6% chance it estimated last October. It also sees reduced risks for a recession in 2015. So while the overall growth expectation has been lowered modestly, the sharp reduction in the possibility for a global recession has to boost the confidence of energy companies that demand will be sustained, meaning that oil and gas prices should be sustained at current levels. Global oil supply disruptions have been supporting crude oil prices, and those disruptions could subside, weaken prices. With stronger economic activity on the horizon, any price reductions should be offset by greater demand. Visually, one of the best ways to see where economic activity and, presumably, energy demand growth should be strongest in 2014 is by examining the map in Exhibit 15.

As the pace of the economic recovery slowly increases, prospects are that 2014 could be a year in which energy companies actually generate stronger cash flows than they, and everyone else, thought a matter of only a few months ago. Improved cash flows may not translate directly into stepped up E&P spending as the mantra of improving financial results and boosting returns to shareholders may cap spending increases at low single-digit rates as originally forecast

Exhibit 15. Seeing Global Strength And Weakness

Source: IMF

for this year. A year of improved financial performance could set the stage for one or two years of greater capital spending primarily directed toward boosting reserves and production. Future spending will still require efforts to improve efficiency of capital deployment. Current industry conditions resemble the phase of a sailboat passing through the point of the wind as it tacks from port to starboard. That point is a no man’s position in which the sailor has to count on his momentum carrying the tack through.

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.