- The Rhyme Of Oil History Should Be Heard And Studied – Part 7

- EV Market Outlook Fuzzy As Subsidies Are Key For Success

- Being An Energy Shareholder Is Not Fun – Will That Change?

Musings From the Oil Patch

January 28, 2020

Allen Brooks

Managing Director

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

The Rhyme Of Oil History Should Be Heard And Studied – Part 7 (Top)

The global oil boom that peaked at the end of 1981 continued to unwind as the decade of the eighties progressed. By 1985, the growing global oil glut was not only evident, it was reflected in collapsing oil prices and unsold oil from OPEC member countries. Mid-1985 witnessed OPEC production fall to a 20-year low of 13.7 million barrels per day (mmb/d). Cheaper North Sea oil was gaining market share. In response, Saudi Arabia elected to link its selling price to spot oil prices, while also boosting its output from 2 mmb/d to 5 mmb/d, putting further downward pressure on oil prices. This was part of Saudi Arabia’s Minister of Oil Ahmed Zaki Yamani’s effort to teach his fellow OPEC members not to cheat on their production quotas. By December, OPEC’s total output was up to 18 mmb/d, and a full-out price war was underway.

Twice during the first half of 1986 (in February and again in June), OPEC members failed to agree on production cuts. By July 1986, Brent oil prices fell under $9 per barrel, which came at the same time as OPEC further boosted its output to 20 mmb/d. The remaining months of 1986 were spent with OPEC members attempting to negotiate a production and pricing strategy, while they watched in horror as oil prices dropped in response to the flood of new crude oil supplies that was coming from around the world due to the extremely high oil prices of the late 1970s. In December 1986, the desperation of OPEC oil ministers led to an accord on the organization’s oil output and a price hike. The problem was that this agreement began to fall apart almost immediately as 1987 began.

With a world swimming in oil, and prices falling to single-digits, it was difficult to justify drilling for new oil. In the U.S., as well as around the world, drilling rig counts dropped. Exhibit 1 (next page) shows how the U.S. drilling had boomed during the 1970s, but became red hot as we moved into the 1980s, only to peak at the end of 1981. The immediate drop in the rig count during 1982 appeared to stop in the spring of 1983. The early 1983 OPEC agreement to limit its output to 17.5 mmb/d and cut prices by $5 per barrel to $29 was thought sufficient to begin addressing the oil market’s weakness. For American oil and gas companies, the dreaded windfall profits tax on oil was over, so profitability was expected to be enhanced.

Furthermore, the oil industry’s enthusiastic reaction to the U.S. government’s change in Gulf of Mexico leasing policy – shifting from a nomination to an open-bidding process – freed producers to evaluate various exploration theories. That shift led to record numbers of offshore leases being acquired, and enthusiasm for launching exploration was high. The problem was that this optimism was overshadowed by the growing global oil glut and the disarray among OPEC members about how best to manage the world’s oil supply.

Exhibit 1. Picturing 1970s & 1980s Rig Boom And Bust

Source: Baker Hughes, EIA, PPHB

The deterioration of the oil industry’s health became increasingly evident in the second half of 1985. The industry’s devastation would really begin to unfold early in the new year. Facing the reality of this devastation, people within the oilfield service sector began working on possible solutions. Shrinking industry capacity would be key for the industry to return to profitability. The continuing deterioration in industry fundamentals made this task that much more difficult, which, in turn, meant it would take longer to shrink industry capacity resulting in greater pain and suffering for the survivors, let alone the devastation wrought on the losers.

One oilfield service sector that was particularly hard hit was offshore drilling. The opening line of the February 1986 Offshore Rig Newsletter stated: “Before the Ides of March, 50% or more of the rigs in the Gulf of Mexico could be laid up.” That ominous forecast cast a pall on the business. The newsletter then devoted itself to a discussion of future exploration and production company capital spending plans. The 1986 E&P budgets that were filtering out into the industry suggested significant cutbacks. The problem was that the failure of the December 1985 OPEC agreement was becoming evident in the oil futures market, as prices headed lower. That turmoil forced many E&P companies to freeze their “just released” capital spending budgets until managements could figure out where oil prices were heading.

The impact of the spending cuts and subsequent freeze was felt nearly immediately in the drilling rig market. As the newsletter wrote in mid-February:

“Since the first of January, mobile rig utilization in the Gulf has dropped 10.6 points, 10.2 points in just the past three weeks. The impact can be seen even more dramatically in the Hughes Tool rig count, which dropped by 402 rigs since the first of the year.”

The Hughes Tool rig count went from 1,915 to 1,496, as oil prices fell by $10 a per barrel from $26.08 to $16.31. A 37.5% drop in the oil price would translate into significant declines in company cash flows.

For offshore drilling contractors, the newsletter suggested:

“If crude prices do not stabilize quickly, it could portend a blood-bath in an already ravaged drilling industry the likes we’ve never before seen. One of the first responses by a drilling contractor to the rapidly deteriorating market was to offer a 225-foot slotted jackup drilling rig at a $7,500 day rate for short-term work. The low ‘teaser’ rate generated comments from operators, but no takers. One submersible drilling rig was contracted at such a low rate, and another large offshore drilling contractor said it could go down to such a level to ‘meet competition.’”

The newsletter offered a view about what might happen to the industry in the coming months, when it wrote: “If crude prices remain unsettled, the consolidation expected in the drilling industry may be all over by July.” That prediction turned out to be highly optimistic. The prediction failed to appreciate how the bankruptcy filing by Global Marine on January 27th, some three weeks before the newsletter’s publication, had changed the calculus for industry restructuring.

As the spring of 1986 unfolded, Russ Luigs, the crewcut wearing boss of Global Marine, told Gary Kott, the head of the company’s offshore contract drilling division, one of the world’s largest offshore drilling contractors, to go work on his golf swing, as there weren’t going to be many employment opportunities for the company’s rigs, especially given the bankruptcy filing and the unsettled spending outlook.

Three hundred and fifty miles to the east, ODECO’s CEO, Hugh Kelly was saying that worldwide offshore rig utilization could be in the range of 40%-50%, and the Gulf of Mexico fleet might only have 25% utilization for the entire year. His marketing staff would show up for the company’s traditional morning operations meeting, only to disappear to a hotel suite they rented in order to spend the rest of their day out of the office and away from employees who actually had some work to do. At one point, the entire ODECO fleet was stacked, as it was felt better to preserve the rigs than wear them out drilling at uneconomic day rates. That survival strategy would change when managers realized that generating some cash was becoming more important than letting their valuable assets rust away in lay-up mode. In 1987, ODECO contracted a semi-submersible drilling rig for $8,600 a day. The cost to operate a semi-submersible drilling rig was probably at least 50% more than that of a jackup, which was being offered at $7,500 a day.

For drilling contractors, from the industry’s activity highs of December 1981 to the lows experienced five years later, the fall was dramatic. As Exhibit 2 shows, over that five-year period, the total U.S. rig count dropped 78%, or more than 3,500 rigs stopped working. The offshore rig count declined 66%, while the inland barge rig market was off 75%. Seeking new oil and gas resources was not something the industry was interested in, or capable of, given the contraction in cash flows and the absence of buyers clamoring for more expensive hydrocarbons.

Exhibit 2. 5-Year Downturn Hurt Every Market

Source: Hughes Tool, PPHB

Figuring out where and how to stack these offshore rigs became a challenge. If you thought there was a chance a rig might go back to work relatively soon, you elected to “warm-stack” the rig. That meant you kept engines running to generate power and you had to keep a skeleton crew onboard to maintain the equipment and protect the rig from any possible damage. That inflated the cost of stacking as you incurred fuel, food, labor, and insurance costs.

On the other hand, it was possible to “cold-stack” a rig. That meant parking it where it would not be a risk of being hit by ships or active vessels hauling materials and provisions to operating rigs and platforms. If engines were going to be turned off, then they needed to be prepared against moisture damaging them. Access points to rig quarters and operating centers needed to be sealed up, and often equipped with dehumidifiers. That necessitated power, but often clusters of cold-stacked rigs could be arranged around a warm-stacked rig with power cables run from the active rig to the cold-stacked ones to power the dehumidifiers.

Parking rigs was a challenge, especially given the different types of rigs – drilling barges, submersibles, jackups, semi-submersibles and drillships. That effort ignored the hundreds of supply, anchor-handling, and seismic vessels, along with tugs that were laid-up. Offshore construction equipment was also parked. Every port from Mississippi to Brownsville on the Texas/Mexico border contained idled offshore equipment, as well as some fairly protected areas in the Gulf of Mexico.

For land drillers, there was virtually no region of the country that didn’t suffer from the downturn. The two most important land drilling markets – Texas and Oklahoma – were battered almost beyond belief. Texas’ rig count fell by 1,079 rigs, for a 79% decline, while Oklahoma’s count dropped 721 rigs, marking an 83% decline. Drillers’ rig-up yards became parking lots, and when that space was exhausted, empty ranch land became the stacking location. For the companies that had geared up for the anticipated extended drilling boom, which meant borrowing heavily to finance new drilling rig construction, the activity collapse forced many of them to the court house seeking bankruptcy protection if they couldn’t engineer a merger or a sale. Chapter 11 proceedings were seen as a way to buy time for either the industry to begin to recover, or for alternative consolidation plans to be proposed. Liquidation was an option, but only as a last resort, and certainly not an alternative step rig owners desired.

Exhibit 3. Leading State Drilling Markets Downturn

Source: Hughes Tool, PPHB

To gain a perspective on how rapidly the oilfield market changed, and how dire the outlook became, one only needs to track the titles of the 1986 monthly Offshore Rig Newsletter issues through July of that year.

January 1986 “First Time In Its History – 1985 Offshore Rig Fleet Records No Growth”

February 1986 “Rig Utilization Is Getting Hit On Two Fronts”

March 1986 “Armageddon For Offshore Drilling Industry? All Say They Can Survive. Can They?”

April 1986 “Offshore Rigs Going Into Hibernation”

May 1986 “Offshore Drilling Industry On Brink Of Massive Transition”

June 1986 “Judgement Day Approaching For Many”

July 1986 “Restructuring – A New Path May Be Opening”

The opening paragraphs of the June 1986 newsletter captured the reality facing the offshore drilling industry. Offshore drilling’s reality was no different from the reality virtually every other oilfield service company worldwide was confronting, along with most oil and gas producers, especially small companies. Major diversified oil and gas companies had downstream businesses – refining, petrochemicals and transportation – that were benefitting from low raw material costs, boosting profits. As they were making more money downstream, they could offset the pain from the collapse in upstream profitability due to the drop in oil and gas prices.

The Judgement Day reference in the title of the June 1986 newsletter dealt with the prospect of companies running out of cash. Editor Jerry Greenberg (a friend and co-worker) wrote in that issue:

“As every day ticks off, the offshore drilling fraternity moves closer to judgement day. For an industry that is operating below cash flow breakeven, it is just a question of time before what little cash is left will be gone. Some might say they can hold out until next year; others are at the end of the line now. But whether a company runs out of money in June or next October is a moot point – the fact is, the condition is terminal.

“But the industry won’t disappear. It will have to go through a physical and financial “restructuring process”. To facilitate this restructuring, a massive write down of assets (rigs) is going to have to occur. Putting it another way, the lenders and rig owners are going to have to accept that the market value of the rigs is next to nil and that the capital structure of the rig owning companies will have to reflect this.”

At the time of the June 1986 newsletter, two large drilling contractors, Zapata Offshore, a part of Zapata Corporation, and Western Oceanic, the offshore drilling arm of The Western Company of North America, were deep in negotiations with their lender Manufacturers Hanover Bank, who had been actively involved in financing the drilling rig construction boom of a few years earlier. These negotiations reflected the tip of the debt iceberg the industry was sitting on. How to resolve the industry’s debt issue was not clear, and it would ultimately prove to be impossible to accomplish without drastic restructuring steps.

From a macro prospective, as the oil industry entered 1986, managers were unsure what the oil price would be given the turmoil within OPEC and the growing oil glut. As a result, producers were cutting their capital spending budgets both from 1985 levels, and in other cases from their preliminary 1986 budgets they had announced late in 1985. The following is a sampling of budget cuts and other cost reduction steps announced by various oil producers during the February to April 1986 time period.

Based on a rough estimate of the E&P spending reductions, the industry was planning to cut 23% of its spending, taking away about $8.5 billion. They also identified probably close to 5,000 jobs being eliminated. Belt tightening by producers proved insufficient. The

Exhibit 4. 1986 E&P Budget Cuts And Layoffs

Source: Offshore Rig Newsletter, PPHB

rapidly deteriorating market required more draconian steps. Thus, as 1986 unfolded the announced capital spending cuts grew and the layoffs increased. These cuts proved devastating for the oilfield service industry, especially the high-cost offshore sector.

The offshore sector had been facing challenges for several years prior to 1986. The huge growth in the drilling rig fleet, as well as service vessels, had added much more equipment than the industry needed, especially as these newer units were substantially more expensive than earlier versions. Given the pricing structure in the offshore business ($750 -$1,000 per day for every $1 million of capital cost of equipment), day rates had escalated eating up large chunks of the oil company capital spending budgets, while not necessarily leading to more reserves and output. Thus, when oil prices began to weaken, and especially after the changes in natural gas pricing undertaken by legislators at the start of the 1980s, offshore operations were ripe for being scaled back.

Exhibit 5. How Offshore Rig Fleet Grew 1950-1990

Source: Offshore Data Service, PPHB

When we look at the growth of the offshore drilling rig fleet from its inception in the late 1940s through the boom years of the 1970s and 1980s, we see several phases of rapid fleet additions. The first was in the mid-1960s, which reflected the early successes in the Gulf of Mexico, and the increased exploration for natural gas in the southern regions of the North Sea. With the jump in oil prices in the early 1970s, and the discovery of large oil deposits in the central region of the North Sea, the growth of the offshore rig fleet surged. High oil prices also spurred exploration and development work offshore in other regions of the world from South America to West Africa to Southeast Asia. But it was the boom during the end of the 1970s, coupled with the use of creative rig financing – limited partnerships, third party lease financing – and the need for the financial industry to participate in the rapidly growing and highly profitable offshore drilling business that led to the huge boom in offshore rig construction.

When the drilling bust came at the end of 1981 – initially due to the drop in natural gas prices and then followed by weakening oil prices – orders for new offshore drilling rigs came to a halt. As a result, only 14 rigs were delivered in 1984 and eight in 1985, after 114 and 67 being delivered in 1982 and 1983, respectively. The last time there had been a two-year period with so few new offshore rigs delivered was in 1970 and 1971 when nine and 14 rigs arrived.

The problems for the offshore drilling industry that led to the cessation of new rig orders meant tough times for rig builders and suppliers of drilling equipment. These market problems also spilled over into the availability of capital to fund construction of new rigs. The 1986 collapse in oil prices was the final nail in the coffin for offshore contract drillers. As a result, there were no new rigs delivered in 1986 through 1989.

Exhibit 6. Ups And Downs Of Offshore Rig Market

Source: Offshore Rig Newsletter, PPHB

A snapshot of the offshore rig market in the mid-1980s highlights how quickly it changed, but possibly more importantly, how marginal shifts in market conditions had a much more dramatic impact on offshore drilling contractor finances. During the five years of 1983 through 1987, we see the offshore market – both the total fleet and the competitive fleet contract, peak and then fall again. The data in Exhibit 6 comes from Offshore Rig Newsletter issues for January of each year. That particular issue always focused on a recap of how the offshore business had changed during the prior 12 months. Offshore Data Services, the publisher of the newsletter and chronicler of all offshore data, used two measures when looking at activity and the health of offshore markets. This involved tracking all offshore mobile drilling rigs, including all of those owned by private contractors as well as oil companies. In many international markets, the country’s national oil company would often own drilling rigs. Because they were essentially captive to the national oil company, only working in the nation’s territorial waters, they were not truly competitive rigs in a commercial sense. The rigs were equally as capable as those rigs owned by private drilling contractors. The quality of the drilling crews might not be as proficient as those working for private offshore drilling contractors, but that was not an issue since they did not have to compete against other companies for work in other countries.

Weak natural gas and crude oil prices in 1984, as the global oil glut and lower U.S. gas prices materialized, resulted in an increase in idle offshore drilling rigs and a drop in the fleet utilization rate. Due to the shift in Gulf of Mexico lease sales from a nomination to an open bidding system, the enthusiasm of producers who acquired record numbers of leases to get drilling resulted in an uptick in fleet employment and a lift to the utilization rate. That momentum was quickly dissipated by falling oil prices.

At the start of 1985, the competitive fleet’s utilization rate was 88%, but it lost 10 percentage points that year. The disaster was in 1986 as the utilization rate fell to only 50%. Even with an improving oil market in 1987, the offshore utilization rate only improved to 66%, probably helped by the competitive fleet shrank by about 3.5%.

While the offshore drilling market seemed to bottom in 1986, the financial strains for contractors had commenced earlier. In fact, they were evident in 1982. A December 1982 Offshore Rig Newsletter focused on strategies contractors were using or considering as they attempted to deal with what was visibly beginning to look like “the most severe oversupply problem the industry has ever faced.” As the article stated, in figuring out a possible strategy for survival, one needed to figure out “how long this bad market will last and to what depths utilization rates will sink.” That would help define the gap between “here” and “there,” and help contractors determine how long a bridge they needed to build to survive. The following is a list of actions contractors were undertaking or contemplating.

“Voluntarily reducing day rates of present contracts as an inducement to operators to extend the contracts, even though they may not expire for another year or so;

“Bidding day rates at cash cost of rig operation;

“Taking long-term contracts at low or break-even rates to insure utilization through the rough times;

“Selling or giving away part of a rig in return for a drilling contract;

“Merging operations and marketing functions with another contractor to reduce overhead;

“Assigning rigs to a larger contractor who will then obtain work on a ‘best efforts’ basis;

“Anticipating the oversupply and doubling up on debt payments before the bad market hits;

“Delaying deliveries and/or cancelling rigs on order;

“Seeking deferral of interest and/or principal payments on loans;

“Utilizing ‘revenue backlog’ to justify low dayrate contracts, which can be averaged with high rates;

“Accepting footage contracts;

“Cutting operating cost by deliberately mothballing equipment;

“Temporarily reduce overhead;

“Intensifying marketing efforts, including advertising in newspaper sections;

“Moving rigs to areas of better potential without a contract in hand;

“Filing Chapter 11 for reorganization under the Federal Bankruptcy Act; and

“Selling the company.”

One could add to that list of actions and rearrange them from the least disruptive to a drilling contractor’s operations, but likely the least financially impactful, too, to the most impactful, but also most draconian. In our memory, virtually every one of those possible actions was tried by contractors. In some cases, multiple actions were tried when the initial ones failed, as contractors moved from the least to most impactful actions in trying to survive.

From 1982 onward, the Offshore Rig Newsletter had been reporting on the financial challenges facing individual contractors, along with the actions they were either taking or contemplating. To appreciate how offshore contract drillers’ fortunes changed over time, and led to restructuring of the industry, we will describe the history of one driller – Blocker Energy Corporation. The company was founded by an oilman steeped in the history of the drilling business, with a record of successes, but who was swept up in the boom that eventually led to his demise. We knew John Blocker, as he had been a senior vice president of Dresser Industries, overseeing a large portion of its oilfield business. But he had drilling in his blood, and he eventually returned to those roots for what turned out to be a wild ride.

John R. Blocker was a member of the Texas A&M Class of 1945, but the war interrupted his education. He fought in the war, earning a Bronze Star. He graduated in 1948 and went to work on an offshore drilling barge until he left to start a drilling company in South Texas with his father in 1954. The company was dissolved in 1958 and he went to work for Dresser Industries as an operations manager in its Argentina and Venezuelan oilfield businesses, utilizing his knowledge of Spanish that he had gained while growing up in South America as his father worked in various oilfields there.

Mr. Blocker moved up the Dresser management ladder, ultimately returning to its Houston headquarters in 1965 as a senior executive in the company’s Petroleum Equipment and Minerals group, a division he ultimately headed up. This group was involved in building drilling rigs and producing the drilling mud vital to the successful drilling of wells. In 1975, he purchased Choya Drilling, a six-rig contractor, based in Alice, Texas. As the company grew, it required greater attention. Thus, Mr. Blocker retired from Dresser in 1977 to focus on the renamed Blocker Energy Corporation, along with his family’s ranch. With industry momentum behind him, Mr. Blocker grew the company by adding additional rigs. Strategically, Blocker Energy diversified its operations into Canada and South America. His plan was to emphasize international drilling markets that tended to be less volatile due to the longer-term focus of the companies exploring there, as well as facing fewer competitors.

In a June 2, 1985, interview with The Houston Chronicle, Mr. Blocker discussed what had gone wrong for the energy business and his own company. As was his nature, Mr. Blocker was open, honest and willing to accept blame for the fact that two-thirds of his company’s shares were then held by his creditors, and his company was a shell of the once booming enterprise. As he told the reporter, "I’ve been sitting here for three years; I’ve had a lot of time to think. You know, you just wonder sometimes how you could be so damn stupid." Mr. Blocker, like so many other energy company managers had listened to the people they thought were experts, including the industry analysts on Wall Street, who told them oil prices could only go up. Oil at $50, $60 and $70 a barrel was thought possible.

At the beginning of 1980, Blocker Energy was the 15th largest drilling contractor, employing over 1,700 workers, occupying four floors in a suburban Houston office building, and growing its fleet of land drilling rigs. In December of 1978, he had hired Raymond Ellison, the former president of Progress Drilling & Marine, to take the company into the offshore drilling business. By May 1981, the company had a posted drilling barge under construction at McDermott’s New Iberia, Louisiana shipyard, and had placed an order for the construction of two submersible drilling rigs to be built at Chicago Bridge & Iron’s Pascagoula, Mississippi shipyard. The posted barge was to be in operation in December 1981, with the two new submersibles scheduled for October 1982 and February 1983.

As Blocker Energy had grown to a fleet of 54 drilling rigs operating in eight countries, it had utilized bank financing to fund its fleet’s growth. In addition, in late 1978, Blocker Energy made a major commitment to exploration by investing more than $50 million in drilling wells, initially focusing on gas wells on his ranch in South Texas, as well as other prospects in that area. Things looked great in the early 1980s, but when the crash happened in 1982, the market softened rapidly putting extreme pressure on contract drillers who saw their rigs idled by producers who were trying to husband their cash flows. The bust prompted consolidation among larger oil companies as Mobil bought Superior Oil, Occidental purchased Cities Service, and Chevron acquired Gulf Oil. Some of these deals were the direct result of the takeover efforts of Boone Pickens, who with the backing of Wall Street money, was making a play to acquire what he perceived to be undervalued oil and gas companies. They were undervalued based on investor shunning energy stocks given the dismal outlook for the industry, but which the optimistic Mr. Pickens expected to become much more valuable once the rough times passed. (Sound familiar?)

Amongst drilling contractors and oilfield service companies, restructuring efforts were just kicking into gear. These efforts were focused on renegotiating loans with the banks who had been the primary financiers for the companies. What bankers wanted was for the companies to cut costs and generate cash, which they said would come from a boost in fleet utilization rates. The first was easy, although painful because it often meant laying off friends, neighbors and relatives. The second, however, was more difficult if the utilization hike needed to be accompanied by increased profits. The easiest way to boost rig utilization was to cut your rig’s day rate, lowering the cost to drill, and making your rig attractive for oil and gas companies to employ. But because of the huge number of idle rigs in the fleet, besides the currently active ones, the competition for the limited number of drilling contracts available led to cut-throat pricing and no profits.

Blocker Energy had gone public earlier as a way to raise capital to expand its rig fleet and to pay down bank debt. Unfortunately, the debt burden continued to grow as the fleet expansion continued but day rates remained under pressure. In June 1983, Mr. Blocker acknowledged that it was willing to consider a merger as a way of addressing his company’s financial problems. One option he didn’t want to consider was bankruptcy, which he saw as abhorrent and an easy way out. Thus, he began working with his eight major bank lenders to restructure the company’s debt.

In early 1984, Blocker Energy shareholders approved a debt restructuring that involved the banks absorbing $120 million of the company’s $223 million of debt. In return for forgiving the debt, the lenders received 28 million shares, boosting shares outstanding from 20 million to 45 million, yielding them a 62% ownership interest. What happened with Blocker Energy was being proposed to a number of contractors and service companies, but often the proposed deals merely extended the negotiations as company executives hoped for a better market that would improve the terms of the likely debt restructurings.

Blocker Energy, with a smaller rig fleet, continued to struggle. At the time of Mr. Blocker’s 1985 interview, the company was working 23 rigs, up from a low of six in 1983. Overall, however, the company’s fleet utilization rates for 1984, 1985, and 1986 totaled 24%, 38% and 24%, respectively. As a result, even after the debt restructuring, Blocker Energy was at risk of having to seek bankruptcy protection. In an effort to avoid that fate, Mr. Blocker went and knocked on the door of the Bass family of Ft. Worth, looking for a cash infusion to facilitate another restructuring without having to face bankruptcy. The effort proved fruitless, but during it, Mr. Blocker met Richard Rainwater who was managing the Bass family wealth. Mr. Rainwater, a highly regarded former trader with Goldman Sachs, advised the Basses to turn down Mr. Blocker.

In September 1986, Mr. Rainwater left the Basses and started his own venture. He was intrigued by what was happening in the oil patch, and he continued to monitor Blocker Energy. He began to consider purchasing some of the Blocker Energy debt from the banks who were certainly receptive to getting out of another troubled drilling contractor loan. As described in ENSCO: The First Twenty Years, the deal that Mr. Rainwater negotiated with the banks and Blocker Energy was designed as a financial play, but it soon morphed into an industry play. The banks and Blocker Energy’s shareholders approved the deal for BEC Ventures, Mr. Rainwater’s partnership, to become the company’s main debt holder. BEC Ventures acquired 65% of the common stock, $12 million of the company’s debt ($83 million of debt was wiped out), and $4 million of Blocker Energy’s preferred stock for $12 million in cash.

Mr. Rainwater, on the advice of Gill Clements, SEDCO’s CEO before its sale to Schlumberger, Gerald Haddock, a prominent Ft. Worth attorney and investor with the Basses, and Morton Meyerson, CEO of the Ross Perot businesses, retained Carl Thorne as a consultant to look at Blocker Energy. His advice was “Don’t touch it.” Mr. Thorne, who had been instrumental in running SEDCO and had stayed on as the head of the offshore contract drilling business formed out of Schlumberger’s merger of its Forex division with SEDCO, had recently retired from the company. When he examined Blocker Energy’s rigs for Mr. Rainwater, he found that only half of the 40 rigs scattered across 10 countries were working, and many were in poor condition. During the 1982-1985 downturn, the rigs had not been maintained and money dedicated to their support had been utilized elsewhere in the company to keep it running. This cash management story and equipment neglect was repeated widely throughout the global contract drilling business. It actually contributed to prolonging the downturn, as oil companies used the existence of the large number of idle rigs as leverage to push down rig day rates. Without knowing how poorly maintained many of these rigs were, there was little a contractor could do to refute the view of a highly competitive drilling rig market. Once old, idle rigs were acquired and cut up, the perception of the vast overhang of idle rigs began to go away, helping drive the industry recovery.

After convincing Mr. Thorne to run Blocker Energy, Mr. Rainwater turned his attention to raising capital to facilitate the growth he was hoping to achieve, as this venture was no longer a distressed debt financial play, but a long-term venture to build a profitable oilfield service company. In the spring of 1987, the company successfully raised $54.2 million through a secondary stock offering, based on the speculative view that the marriage of a financial genius in Mr. Rainwater with a top drilling industry executive in Mr. Thorne would prove successful.

ENSCO proved successful under the leadership of Mr. Thorne, and the financial advice and guidance of Mr. Rainwater. (We were a part of that success.) In 2005, ENSCO reached the one billion-dollar revenue threshold. It prompted Mr. Thorne to say about the Blocker Energy venture: “We saw some fits and starts, but we went 18 years before we ever were really sure that we were in the midst of the recovery. So we placed a hell of a bet.”

A key to building ENSCO, after failed attempts to acquire Anson Drilling and Gearhart Industries, was its focus on offshore drilling. From a couple of jackup rigs, the assets of an offshore supply vessel company were added, along with the construction of a fleet of barge drilling rigs for Venezuela. The key move for the company was the acquisition of Penrod Holding Corporation in 1993, which added 19 offshore drilling rigs to the company’s fleet and set it on the road to becoming one of the major global offshore contract drilling companies.

Although Blocker Energy was primarily an onshore contract driller, its problems and failed restructuring attempts were being repeated throughout the oilfield service industry. The offshore contract drilling sector, due to the recent proliferation of new entrants saddled with huge debt loads had fragmented the industry much more than it had been only a decade earlier. This fragmentation, coupled with the desire for lenders to see the rigs they had financed working and generating cash, led to a rapid cannibalization of the industry’s dayrate structure such that no one was making a profit. Many rigs were working below cash costs, based on the view that any cash coming in was better than cash flowing out to sustain rigs that were stacked.

In spring 1986, John Huff stepped down as president of Western Oceanic, Inc., the offshore contract drilling division of The Western Company of North America, founded by Eddie Chiles, who was also the owner of the Texas Rangers major league baseball team in Arlington, Texas. He was famous for one of the classic advertising campaigns during the oil boom. The ad ran: “If you don’t have an oil well, get one. You’ll love doing business with Western.” He was possibly more famous for his rants against Big Government! He would begin his rants with: “I’m Eddie Chiles and I’m mad.” This would be followed by a rant about some aspect of government involvement in business or people’s lives. This campaign emerged during a period when those in Texas, and especially those in the energy business, were being vilified over high oil prices that resulted in high gasoline prices. As Eddie Chiles’ campaign grew, it prompted bumper stickers across Texas and the Southwest with the phrase, “I’m mad, too, Eddie.”

Mr. Huff left his position with Western Oceanic over a disagreement with Mr. Chiles about how the company should respond to the industry downturn. After exiting, Mr. Huff began promoting a plan to spur industry consolidation as a way to return the offshore drilling industry to profitability. He was pictured on the cover of the May 1986 Petroleum Management magazine, in which he was interviewed by a reporter about his plan.

Exhibit 7. Offshore Drilling Industry Consolidation

Source: Allen Brooks

Industry consolidation had been talked about off and on, but was not making any progress as a solution to the devasting industry conditions. Mr. Huff commented:

“I think the industry needs to carefully consider consolidation as a viable path to cure today’s financial woes. There are several options available to make matters in the offshore drilling industry better but I don’t think one company can do it alone. However, if companies act responsively and with responsibility, these problems can be solved.”

Mr. Huff pointed to the “explosive” industry growth of the past 15 years as the problem. He pointed out that there were about 100 rigs working offshore in 1970 and by 1985 there were over 700 rigs available. That was, in his estimation, too much capacity. He cited that “The industry had a low entry threshold during that time span” as the primary problem. As he put it, “…during the 70s, when virtually all you had to do to be in the offshore drilling industry was get a contract, borrow money on the strength of the contract and have rig fabricated.” This led to a highly fragmented industry, over capacity, low day rates and the inability to make a “simple operating profit.”

The benefits of consolidation were many, according to Mr. Huff. He said:

“It will help structure and reduce administrative costs on a per unit basis; maintain a higher potential to provide good quality of service for customers; increase the probability that a less fragmented industry will emerge; maintain a higher possibility that investors will get a reasonable return on their money; stabilize prices, possibly with the help from an independent organization like the U.S. Maritime Administration; increase the probability that creditors will get their loans repaid; and, after the market settles down, provide a system where each surviving company can be competitive based on quality of service with the subsequent market shares being divided by differentiated service quality.”

As part of the plan, older rigs would need to be scrapped and cut up in order to reduce the number of rigs competing for each drilling contract. Consolidating the ownership of the remaining rigs would lead to higher day rates, but because there were spare rigs, day rates wouldn’t have to increase in order to ration rig supply and attract the capital to build new rigs. A key component for making this plan work involved having the Maritime Administration, which had guaranteed the loans for roughly 60 offshore rigs, of which half were delinquent and the other half on the brink of delinquency, foreclose on all the rigs, mothball them, and then feed them back into the market when additional supply was needed to prevent a spike in day rates. In his view, this would be similar to what the Agriculture Department does to stabilize crop prices. The one problem with this analogy is that each drilling rig in unique. While many of them are carbon-copies of others because they were built to the same design and by the same shipyard, they might be equipped with slightly different drilling components, and they certainly would have different drilling crews, some of whom might be more efficient than others. In other words, offshore drilling rigs were not like kernels of corn.

Mr. Huff’s plan became the basis for a new company that he formed with Paul Lloyd, the president of Griffin Alexander, a medium-sized offshore drilling contractor built on a foundation of a number of limited partnerships. Mr. Lloyd had been the architect of a number of limited partnership offshore drilling contractors. Falcon Partners, the holding company, was to be funded with money from investors, which would be used to make working capital investments in contractors and provide sufficient cash reserves to stack and maintain the acquired rigs for a certain period of time. The contractor’s present lenders were to agree to debt levels at a fair market value for the rigs in return for the working capital loan and an additional preferred equity layer and the opportunity to participate with Falcon Partners’ owners in the success of the venture.

At the time the formation of Falcon Partners was announced, news surfaced that the Hunt family (the children of oil tycoon H.L. Hunt) and their drilling and E&P companies, Penrod and Placid, had filed suit against 23 U.S. and Canadian banks charging them with deception and fraud in a conspiracy to destroy the companies. The Hunts and their companies were seeking more than $1.2 billion in actual damages, with the possibility of a trebling of that amount plus punitive damages. The banks countersued and the legal battle began. (We were retained to assist the Hunt law firms in understanding the offshore drilling market.)

At the core of the Hunt lawsuit was the anticompetitive workings of an offshore drilling industry consolidation plan developed by Robert Wagner, a senior loan officer at First City Bank in Houston and floated to a handful of other commercial banks with offshore contract driller loans. The “Wagner Plan,” supposedly verbalized as early as 1985, involved moves such as those outlined by Mr. Huff in his industry consolidation scheme. The Hunt claim was that the Wagner Plan was to “develop a concept to minimize creditor losses in the near term while maximizing longer term values for those creditors.” The plan envisioned a plan whereby “6-10 contractors controlling 500+ rigs will result in a much more orderly market and we believe that, looking at a list of the 25 (largest U.S. independent) contractors such a consolidation is possible over the next 3-4 years.” The plan continued, “The goal of consolidation would be to combine fleets under one management team, build the largest possible fleet, and let the cash savings flow to the priority claimants involved.” Those claimants would be the banks holding the loans on the drilling rigs to be included in this monolithic driller.

Suffice it to say, the Hunt lawsuit failed and the family lost its premier drilling company and E&P operations. Out of the ashes of the Hunt lawsuit came the seeds for the creation of global driller ENSCO. Today, ENSCO has a new name, Valaris plc, following its merger with Rowan Companies to form one of the world’s largest offshore contract drillers. Interestingly, Rowan began life as an onshore contract driller in Ft. Worth before moving to Houston and transitioning into offshore drilling, much like the ENSCO story with its earlier chapter as Choya Energy/Blocker Energy.

Variations of the ENSCO/Blocker Energy story can be found in the history of the creation of most of the other major offshore drillers. For example, a timeline of Transocean’s history, and the offshore drillers it acquired over the years, provides an interesting snapshot of the disastrous market conditions and the debt challenges offshore drillers faced in the 1980s and 1990s.

1942 Forex formed

1946 Santa Fe Drilling Company formed

1946 CUSS group formed by Continental Oil Co., Union Oil of

California, Superior Oil, and Shell Oil

CUSS eventually becomes Global Marine Drilling

1947 Sedco formed

1950 The Offshore Company created as a subsidiary of Southern

National Gas

1963 International Drilling Co. Ltd. acquired by The Offshore

Company

1981 Kuwait Petroleum Corp. buys Santa Fe Drilling Company

1982 The Offshore Company becomes Sonat Offshore Drilling

Company

1984 Schlumberger buys Sedco

1985 Schlumberger merges Forex and Sedco to form SedcoForex

as its drilling division

1987 Sonat buys Dixilyn-Field from Panhandle Eastern Company

1993 Sonat spins off Sonat Drilling Company

1996 Sonat buys Transocean ASA becoming Transocean

Offshore Inc.

1997 Kuwait Petroleum divests Santa Fe Drilling Company

Reading & Bates merges with Falcon Drilling Company

1998 R&B/Falcon acquires Cliffs Drilling Company

1999 SedcoForex spun off by Schlumberger and merged with

Transocean Offshore Inc.

TransoceanSantaFe formed

2001 TransoceanSantaFe and R&B/Falcon merge

Global Marine and Santa Fe Drilling merge to form

GlobalSantaFe Corp.

2007 Transocean and GlobalSantaFe merge

2011 Transocean acquires Aker Drilling ASA

2018 Transocean acquires Songa Offshore

Transocean acquires Ocean Rig UDW

The merger activity during the 1980s and 1990s was largely the result of the financial and business challenges from the industry bust and the need for contractors to increase scale and financial strength for the next phase of offshore exploration. The global deepwater drilling boom was evident after 2000 in the surge of new rig construction. While the number of rigs built in any one year did not match the annual number built during many of the years of the late 1970s and early 1980s, the cost of the new rigs was much greater due to their greater sophistication and capability.

Current contractor financial struggles are related to the debt drillers took on to build their modern rig fleets. Once again, expectations for ever higher oil prices and, in this case cheap money, contributed to the excessive use of debt to finance rig construction. That debt still weighs on companies and likely will continue until further industry consolidation occurs.

Exhibit 8. The Offshore Drilling Rig Building Booms

Source: Offshore Data Services, PPHB

Debt was also a contributing factor in the restructuring of other oilfield service businesses during the 1970s and 1980s energy boom and bust. Debt facilitated the expansion of oilfield service companies during the industry’s good times, just as in the drilling sector, and the mid-1980s bust and slow industry recovery forced a resizing of the industry to match the lower volume of work expected during the 1990s. Although debt is only a four-letter word, it has possibly been more responsible for the energy industry’s cycles and the destruction of value than either crude oil or natural gas prices. The latter are assigned greater responsibility because no one wants to admit they fell under the spell of “group think.”

EV Market Outlook Fuzzy As Subsidies Are Key For Success (Top)

Elon Musk, CEO and founder of Tesla, Inc. (TSLA-Nasdaq), was shown on television recently dancing during a ceremony at the company’s new Gigafactory in Shanghai, China. He was celebrating delivery of the company’s first Model 3 vehicles to the public from the factory. Earlier deliveries were to employees, enabling Tesla to assess the quality of vehicles manufactured in the start-up factory.

A week ago, Tesla confirmed it had purchased land outside Berlin, Germany for a Gigafactory to satisfy European market demand. These expansionary moves by the electric vehicle (EV) maker signals that Mr. Musk and his executive team believe they must aggressively position themselves in the other two major EV markets – Europe and China. After being slow to focus on EVs, Germany is rapidly becoming a major EV growth market. It is also where Tesla’s major competition is based. These competitors, including Volkswagen AG (VWAGY-OTC), the world’s largest car manufacturer, and other luxury car manufacturers, such as Mercedes-Benz (DDAIF-OTC) and BMW (BMWYY-OTC), are accelerating their efforts to gain a significant presence in the EV luxury and Sport Utility Vehicle markets globally.

Mr. Musk’s dance seemed to coincide with the rise in Tesla’s share price. Some analysts had recently upgraded the stock and boosted their price targets, however, one analyst downgraded the shares after the price jump. Ark Investment Management, who specializes in finding and investing in disruptive technologies that the fund managers believe will revolutionize important sectors of the global economy, recently raised its view of Tesla’s potential worth. Catherine Wood, the firm’s CEO and founder, spoke about Tesla CNBC. She said that her firm believes the company will trade at $6,000 per share in five years. That is up from Ms. Wood’s first prediction in February 2018 of Tesla trading at $4,000 per share. Assuming Tesla doesn’t issue additional shares, based on the $6,000 price, the company’s market capitalization would be over $1 trillion, a tenfold increase over its current nearly $100-million value. (We are not passing judgement on Tesla’s stock price.)

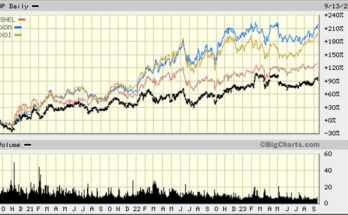

Exhibit 9. Tesla Stock Price History

Source: Big Charts, PPHB

As Ark has been the most bullish investment firm on EVs and Tesla’s preeminent position in the EV market, even more so than Bloomberg’s New Energy Finance (NEF) unit, we have followed the firm’s research closely. Two weeks ago, Ark released its “Big Ideas 2020” report focusing on and updating the firm’s disruptive investment themes. While a number of the Big Ideas are of interest from the viewpoint of how our economy may work in the future, which impacts energy demand, we were most interested in two ideas. Those were: “Electric Vehicles — Faster Adoption Than Most Think,” and “Autonomous Ride-hailing — The Future of Transportation.”

Ride-hailing has been presented as an aspect of the transportation system’s reimaging that includes the development of autonomous vehicles. Together these technologies (or system modifiers) would help in the transition of the global vehicle fleet to EVs. While Ark focuses on the investment merits of the firms providing ride-hailing services, we were interested in one chart in the presentation that showed the cost of owning a vehicle. According to Ark, the cost of owning a car, in inflation-adjusted dollars, has not changed since the Model T was first introduced by Henry Ford. We found it curious that Ark used a 1934 date for its first automobile. That was six years after Mr. Ford stopped producing the Model T. The Model T was introduced in 1908 and due to its popularity, the moving assembly line was created to reduce manufacturing time. The initial line allowed for a Model T to roll out a new car every three minutes. The revolutionary assembly line enabled the Model T to be priced at $500 during its peak production years, making it a mass market vehicle and promoting the Automobile Age in the 1920s.

Exhibit 10. Low Ride-hailing Cost Upends Auto Ownership

Source: Ark Investment

Ark’s research has concluded that the cost to operate ride-hailing vehicles will decline to $0.25 per mile, in 2024, down from $0.70 for today’s internal combustion engine (ICE) cars. The new 2024 ride-hailing price is down from Ark’s 2019 estimate of $0.35 per mile. The reason for the cost decline was not explained.

The more shocking forecast is Ark’s view of the EV market, given the current sales declines being experienced, especially in China, the world’s largest EV market. We have been tracking the Chinese EV market as the government has struggled with a weakening economy and a sluggish automobile sector. Not only is China’s auto industry struggling, but so is the entire world’s auto market.

According to LMC Automotive, based on public data, the global light-duty vehicle market in December grew 1.1% year-on-year. For all of 2019, vehicle sales fell 4.4% to 90.3 million units, down from 94.4 million in 2018. Their view was that both December and the year results were “unimpressive.” The results were helped by strong December sales in Europe, but hurt by the consumption tax increase in Japan, rising vehicle prices in the United States, and the continuing problems for China’s vehicle sales. In fact, Chinese automotive sales through October had declined for 16 consecutive months. Based on our reading of Chinese automobile statistics, both November and December experienced year-over-year declines. The good news is that December’s year-over-year decline was only 0.1%, helped by a comparison against weak sales in the prior year’s December rather than any robust sales rebound this year.

Exhibit 11. The World’s 20-Year Auto Sales Record

Source: LMC Automotive

Exhibit 11 shows the annual sales figures for the global light-duty market. One can see the flat market that dominated the 2000-2003 period due to recessionary economic conditions. After climbing steadily until 2008, the financial crisis and recession knocked sales down, but they recovered quickly and continued on the 2004-2008 projected sales trajectory starting in 2010. That growth continued until market hiccups in 2015 and 2016, but the real market volatility was experienced in 2017-2019, with sales for the last year settling noticeably lower. China’s economic issues of the past two years were clearly evident in its automobile sales. As a result, the government undertook to stimulate car sales in an effort to boost economic growth, even though their action hampered the New Energy Vehicle (NEV) market for EVs. There were other problems impacting the NEV market, as cars experienced battery fires and recalls raised questions about the quality and safety of these vehicles.

EV-volumes.com wrote about the Chinese vehicle market and its problems, especially as they relate to the recent and current market for NEVs. They wrote:

“NEV subsidies were reduced several times in past years. The current trend reflects more than just lower demand from reduced handouts. NEVs may experience their first confidence crisis: The Government now pushes for quality instead of quantity, for competition instead of subsidies, OEMs fall back to more profitable ICE production, consumers lose faith in struggling NEV makers, and over-optimistic vehicle specification claims. Aftermarket support is lagging and there have been battery fires. On top of that, purchase taxes on conventionally powered vehicles have been reduced by some percent in order to stimulate the vehicle market.”

Exhibit 12. A Bad 2nd Half Of 2019 For China EV Sales

Source: EV-volumes.com

As a result of these challenges, EV-volumes.com commented about how NEV sales predictions in 2019 were playing out. As they stated, at the end of 2018, NEV sales of two million units was considered plausible, but even after the strong first half, the deteriorating automobile market and the subsidy reductions led forecasts down into the 1.5-1.6-million-unit range. Following July’s negative 2% results, forecasts were lowered further to 1.1-1.2 million units for all of 2019, essentially a no-growth year. Based on sales data through October, EV-volumes.com estimated 1.164 million NEVs would be sold during 2019. Actual sales appear to have been about 42,000 units greater than implied by the estimate, as December rebounded from 95,000 NEVs sold in November to an estimated 148,000 units. These monthly sales represented a 43.7% decline for November and an estimated 26% drop in December. A positive point that people will seize on is that the NEV market share rose above the 4.6% estimate, reaching 4.7%. That better performance, however, was helped by a greater decline than forecast for overall Chinese automobile sales.

The most telling point about the future of the NEV market made by EV-volumes.com was:

“The fundamentals, like Government targets for EV deployment, ICE restrictions, EV portfolios and charging infrastructure investments speak for further NEV growth, but we do not see the sector returning to the relentless 60-100 % growth rates of previous years.”

None of the problems in the Chinese automobile market or its NEV segment has dissuaded Ark from its wildly bullish view about the global EV market. Their optimism is predicated on the application of Wright’s Law that says for every cumulative doubling of units produced, the cost of a battery will fall by 18%. In their Big Ideas presentation, they show the chart in Exhibit 13 (next page) and point to how accurate Wright’s Law has been for projecting EV battery costs. Their forecast projects that battery costs per kilowatt-hour (kWh) will continue to fall well below $100, which has been considered the point at which EVs become cheaper than ICE cars. Ark believes that cross-over point will come in 2022.

Exhibit 13. Key To EV Sales Is Battery Cost Trend

Source: Ark Investment

Ark says that in 2018, an ICE car cost $20,000 less than an EV, but that the gap will be only $9,000 this year. In 2022, EVs will have a $1,000 cost advantage over an ICE car, and that advantage will grow to $8,000 by 2024. From this vantage point, EVs will clearly be superior vehicles to ICE cars based on cost. The typical EV will have a range of 250 miles, but little is said about the adequacy of the EV charging network outside of homes. Admittedly, the number of charging points is growing, but still appears to be inadequate for a mass conversion of the American, let alone the global, vehicle fleet. Nevertheless, Ark seizes on the fact that the Energy Information Administration (EIA) [a name they mis-identify in their Big Ideas presentation] has consistently raised its EV forecasts, suggesting the agency is behind the curve in forecasting what is and will happen to the automobile fleet. In particular, Ark points out that the EIA consistently forecasts a leveling out of the growth rate in EV sales after 2025, ignoring traditional technology uptake rates. As a result, Ark has a dramatically different forecast for U.S. EV sales compared to the EIA.

Exhibit 14. Ark’s Optimistic EV Sales Forecast Vs. EIA

Source: Ark Investment

Based on its view of the improvement in battery costs and the cross-over in costs versus ICE cars in 2022, Ark believes EV sales could grow from two million units in 2019 to 37 million in 2024. As the 2019 data suggests, EVs globally account for slightly over 2% of automobile sales. If the global automobile market grows 10% between 2019 and 2024, or hits 99 million units, Ark’s forecast of 37 million EVs would represent a 37% market share. Their chief concern in reaching this market target is the ability of the automobile industry to scale up manufacturing capacity for EVs. We would agree, but also suggest that customers may not be quite as eager to buy EVs if they perceive a steady improvement in quality and vehicle choices, as well as reduced costs that come from lower battery costs. Never mind the competition among automobile companies that traditionally comes when they introduce new models.

Another article about the rapid growth coming for the EV market, authored by the University of Houston Energy Fellows, points to a chart from a J.P. Morgan research report showing a 5-to-1 spread in the cumulative EV fleet size by 2030. That spread is a reflection of how fast each forecast projects annual EV sales growing. The faster the sales rate, the larger the cumulative EV fleet.

Exhibit 15. Range Of EV Sales Forecasts Is Wide

Source: Modified from J. P. Morgan

In the view of the authors of this article, financial subsidies will continue to play a significant role in the growth of the EV market. EV sales in the Chinese, U.S., and certain European markets have shown that every time subsidies are reduced or withdrawn, EV sales dropped. This has become essentially a Pavlovian response to cost subsidies. That is not surprising because EVs are more expensive vehicles to purchase and they add a certain complexity factor to an owners’ vehicle usage. A chart from the UoH article points to the record of sales jumping in the month preceding the ending of tax subsidies for EVs in the Netherlands. That chart is probably one of the best examples of a Pavlovian response to losing a tax break.

Exhibit 16. Netherlands EV Sales And Tax Subsidies

Source: Modified from UC Davis Institute of Transportation Studies

When EVs truly become cost competitive with ICE cars, and owners are less concerned about range anxiety and willing to be inconvenienced by the time needed for charging their vehicles, EV sales growth will take off. That ignores the potential help that could come from political action restricting the sale and use of ICE vehicles. Currently, the answers to these key issues are what will determine the accuracy of EV market forecasts. We think the more optimistic forecasts are assuming favorable outcomes for every issue and that the outcomes come quickly, something experience suggests seldom happens. Count us skeptical of Ark’s 37 million annual EV sales in five years.

Being An Energy Shareholder Is Not Fun – Will That Change? (Top)

Investing in energy stocks sometimes feels like you are pretending to be a Texas wildcatter. Some of the famous ones listed on the Texas State Historical Association website under “Oil Entrepreneurs and Wildcatters” were famously successful and are associated with prominent energy and oilfield service companies. Those listed on the site experienced both successes and failures in the oil patch and in business, but on balance they won more often than they lost. What their histories suggest is that the oil business was not for the faint of heart. The past decade-plus of investing in energy stocks has reinforced that view. The daunting question is whether the future will prove to be a more favorable environment?

Over the course of 2019, oil prices (WTI) rose. They went from $45.41 per barrel on January 1st to $61.06 on December 31st. The increase was helped by the rebound from the disastrous fourth quarter of 2018 when oil prices dropped by 38% from $75.30 per barrel, as traders began to sense a possible unraveling of the agreement between OPEC and Russia to curb oil output in order to try to prevent another global oil glut from forming. Global oil prices were moving higher as we headed into the fall of 2018, but traders worried Russia might abandon the OPEC agreement, or at least reduce its commitment, in order to capitalize on the higher oil price. The fear of more oil in the market in 2019 caused oil prices to drop like a rock in the fourth quarter, forcing energy companies to pull back their planned capital spending. The future for the industry was certainly looking dark.

That view changed when OPEC and Russia agreed, at the organization’s meeting in December, to extend their output cuts well into 2019. This agreement, despite the market’s waiting to see if it was only an agreement on paper, slowed the oil price decline and eventually established a bottom for oil prices.

All of this suspense in the fourth quarter did little to help the energy stocks in the Standard & Poor’s 500 Stock Index, as the sector’s 2018 performance was an 18.1% loss. With oil prices rebounding and investors believing Armageddon for the energy sector had been avoided, it was reasonable to expect energy equities to do better in 2019. We now know that actually happened. However, even with an 11.8% positive performance, energy ranked as the worst performing sector within the S&P 500 Index for 2019.

Exhibit 17. Energy Investing’s Dismal Performance Record

Source: Novel Investments

A color-coded chart showing the absolute annual investment return performance of each S&P 500 sector, along with its relative ranking each year shows that energy (light green) was the worst performing sector for both 2018 and 2019. It was the second worst performing sector in 2017. Those three years of poor performance contrast with energy being the top performing sector in 2016. That good year was following two prior years of bottom sector performance.

In hindsight, it is hard to believe energy was the best performing industry sector in the S&P 500 Index in 2016. We forget the optimism spawned by the uptick in oil prices that convinced many investors the energy industry’s cyclical downturn that had commenced in mid-2014 was coming to an end. The oil glut swelled and Saudi Arabia decided to add supply to regain lost market share rather than defend OPEC’s oil price target.

Investor optimism about 2016 being a rebound year was based on the view that OPEC had to secure higher oil prices in order to balance their nations’ budgets. However, OPEC oil producers had learned years earlier about deficit spending – seemingly long before American politicians adopted it as a means to please voters. What OPEC couldn’t overcome, however, was the surge in new crude oil supplies arriving in response to the earlier years of $100-plus oil prices. Without a rapidly growing global economy – something that was hamstrung by the era of high oil prices and weak oil demand – it was virtually impossible to avoid an oil glut and sharply lower oil prices. The industry woke up during 2016 to the reality that this was not going to be a typical oil industry cycle.

The investment firm that compiled the chart on S&P 500 Index sector performance listed the best and worst performances for each sector as well as its annual return against the index. For energy, the best year (+34.4%) happened in 2007, while the worst year (-34.9%) occurred the next year. Those returns were certainly helped by $100 a barrel oil prices in 2007, but the oil price collapse and liquidity fears in 2008 forced energy companies to retrench, cut spending and lay-off employees. What is most interesting is that over 2007-2019, energy returned 2.51% annually versus the S&P 500 Index. This was the second worst sector performance, only beating financials by 0.15% annually. Surprisingly, energy’s annual return was beaten 2.7 times by the annual performance of materials stocks, often thought to suffer from similar cyclical investment pressures as energy.

It is also important to note that there are other measures of energy sector investment returns besides the energy stocks within the S&P 500 Stock Index. For example, there is the Energy Select Sector SPDR Fund (XLE) which captures a broad array of energy stocks. That fund saw its price fall from 63.78 to 59.12 over the course of 2019, a -7.3% performance. Another upstream-oriented fund, SPDR S&P Oil & Gas Exploration & Production ETF fell from 30.54 to 22.57 during 2019, down 26.1%. Likewise, the PHLX Oil Service Sector fell from 96.14 at the start of 2019 to 74.99 at the end, down 22.0%, but it bounced off a 60 bottom three times during the year. Thus, while the energy sector of the S&P 500 Stock Index generated a positive return, not all energy sectors performed well.

Exhibit 18. Only Two Glory Periods For Energy Shares

Source: S&P, PPHB

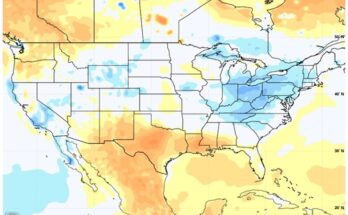

Possibly a better measure of the challenges facing the energy business has been to track the sector’s weighting within the S&P 500 Stock Index. Although oil prices have rebounded in the past few months, they have been lifted mostly be increased geopolitical tensions – first the missile attack on Saudi Arabia’s oil production and processing infrastructure and then by the killing of Iranian military leader Qasem Soleimani. In both cases, fear about the event’s impact on global oil supply caused short-lived price spikes. More recently, the turmoil in Libya and the loss of its output boosted oil prices, but it is questionable how long-term the impact may be given the significant oil volumes being withheld from the marketplace and continuing oil production growth from major suppliers. The potentially bigger question is what would happen to world oil prices should there be an overthrow of the current theocracy ruling Iran. Would the world welcome a less terrorist-dedicated government and begin to lift Iranian economic sanctions that have crippled its oil industry and exports? Some geopolitical strategists suggest such a development could send global oil prices down closer to $40 a barrel than their current mid-$50s. What would that mean for energy stocks? We now have a Chinese virus fear that could crimp global oil demand and is weighing on the oil price.

Exhibit 19. Energy Followed Oil Until After Great Recession

Source: S&P, EIA, PPHB

Exhibit 19 shows how the energy sector weighting in the S&P 500 Stock Index tracked the oil price up until the spike in prices above $120 per barrel in 2007, shortly before the financial crisis and resulting recession crushed oil prices. Although oil prices rebounded sharply following the 2009 recession, other than a brief rise in the sector’s weighting then, it has been steadily declining until hitting a 40-year low at the end of 2019 at 4.3% of the index. This slide in the weighting came despite multiple years of oil prices trading above $100 a barrel. The sector slide suggests that the stock market (often considered smarter than forecasters) was telling us that this downturn would be as severe as the industry experienced following the 1980s oil and gas price drops and the resulting destruction of the oil and gas and oilfield service industries as we knew them.

The current energy sector weighting may be telling us that major changes still lie ahead for this industry. Until those changes are made, and sustained profitability returned to the industry, it is hard to see investors embracing energy stocks. Yes, they are likely to be trading vehicles as they have been in past periods, but the changes underway in how equity investing is done – more passive funds – will likely limit the sector’s attractiveness. Add to the changing management of investments is the challenge of demonstrating sustainability of energy companies. Investors clamor for evidence energy companies can live within their cash flows, while deleveraging their balance sheets, returning cash to shareholders and battling anti-fossil fuel forces around the world. This is a difficult investment world for energy companies. One ray of sunshine in this otherwise dreary outlook is that stocks often climb a wall of worry about their future. That could be the surprise for energy stocks in 2020.

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.