- No One Predicted This Downturn. Was Anyone Watching?

- Hydrogen: Miracle Clean Fuel, Or A Financial Disaster?

- Do Offshore Wind Economics Meet Lower Cost Claims?

Musings From the Oil Patch

August 11, 2020

Allen Brooks

Managing Director

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

No One Predicted This Downturn. Was Anyone Watching? (Top)

Starting at the end of last year and continuing into the early months of 2020, we wrote a series of articles dealing with the history of the business cycles of the oil and oilfield service industries. We wanted to answer the question of how bad the current downturn is in relation to the one experienced in the 1980s. Today’s energy world is dealing with twin black swan events: a global demand collapse, as economies shut down to fight the coronavirus pandemic, and a supply shock from a price war between the second and third largest oil exporting countries – Saudi Arabia and Russia. These black swans drove West Texas Intermediate (WTI) oil prices into negative territory – something never experienced before. Chalk one up for the current downturn!

A critical question is whether this downturn reflects a new cycle for the oil and gas industry, or merely a continuation of the downturn that began Thanksgiving Day 2014? We have charts showing both scenarios, allowing the reader to decide. In our view, the 2020 collapse is an extension of the 2014 downturn, rather than a new cycle. If viewed that way, it makes for a more interesting comparison of the current cycle to the 1980s downturn.

Exhibit 1. Tracking Oil Prices In Downturns

Source: EIA, PPHB

When considering 2020 as marking a new cycle, Exhibit 1 shows the oil price record for 2014-2016, 2018-2020 and 2020 to now. In all three declines, the initial drops were similar, although the latter part of the 2020 decline has proven to be much worse than either of the prior cycles. In fact, we wound up in negative territory, before quickly rebounding. There were a number of reasons why we fell below zero, but they were largely unique. Overall, the similarity in the broad shapes of the oil price movements, especially the 2014-2016 and 2018-2020 cycles, at least until the last portion of the history, supports the view of 2020 being a new cycle.

Exhibit 2. Maybe We Are In A Long-Term Cycle

Source: EIA, PPHB

On the other hand, one can make a very strong case that the 2008 peak in oil prices began an extended cycle that is mirroring the 1980 downturn. Exhibit 2 demonstrates that view. The earlier downturn included the 1986 collapse in oil prices to below $10 per barrel in nominal dollars when Saudi Arabia abandoned support for OPEC’s marker price. That cycle lasted for 20 years. This cycle has its own Saudi Arabia move to disavow the OPEC price, as it strove to recapture market share lost to the U.S. oil shale business. Both events happened five years after the peak in oil prices.

We always wondered whether BP plc’s CEO Bob Dudley 2015 comment that “I do think the industry needs to prepare for lower for longer,” was a reflection of him recognizing that the 2014 downturn was not going to be a typical short-term industry cycle. Mr. Dudley coined the “lower for longer” phrase during interviews at the 2015 World Economic Forum in Davos, Switzerland. The phrase was highlighted during a CNBC interview, and reinforced when he spoke during CeraWeek in April 2015 in Houston. In the various forums, when pressed, Mr. Dudley talked about “longer” being at least three years. So, maybe he wasn’t thinking about the 1980s cycle.

Our friend and former competitor Jim Wicklund recently commented about how significantly the oilfield service giant – Schlumberger, Ltd. – was being impacted by the current downturn. His comments came after the company reported its 2Q 2020 earnings results. His firm’s analyst suggested that Schlumberger’s earnings per share were unlikely to exceed $1.50 in the foreseeable future. He was talking about a company positioned by its technology offerings, its global scale, and reputation for outstanding executive leadership, to be capable of earning a multiple of the analyst’s peak per share estimate. Mr. Wicklund was commenting on changes underway in the oilfield service industry and at Schlumberger due to the downturn, but his conclusion was profound: “Our first point is that no one, not even the biggest company out there, saw the downturn coming that we have lived through for the past five years.”

That statement got us thinking about this downturn. The first realization was that we are barely four months away from completing the SIXTH year of this downturn! Of course, if you believe we have just started on a new cycle, then we are only six months into it. So far, as our chart above shows, 2020 has been a more severe industry downturn, at least measured by the fall in oil prices and its accompanying collapse in oilfield activity, than seen in the past. If 2020 marks the start of a new industry cycle, we can establish an interesting historical pattern. Working backwards from when industry downturns started, we have the following record:

- 2020 – the twin black swans of an oil demand and supply shock

- 2014 – Saudi Arabia’s decision to end support for OPEC’s oil price and regain market share

- 2009 – the global recession following the financial crisis

- 2001 – the recession associated with the 9/11 attacks and the ending of the dot.com stock market boom

That is an interesting list of downturns, notable in that they are 5-8 years apart. The challenge in continuing this pattern is that the next earlier downturn was associated with the 1998 Asian currency crisis, which occurred at the same time Saudi Arabia stepped up its output intending to capture market share in Asia as that region’s economic growth was projected to surge. When Asia’s growth failed to materialize due to currency problems, oil prices dropped. That downturn was barely three years earlier than the 2001 downturn, raising questions about whether that fits our cyclical pattern.

A greater problem for the historical cyclical pattern is that one must strain to find anything looking like an industry downturn, between 1986 and 1998. If there wasn’t a clearly identified industry cycle during that span, it becomes harder to argue that the oil and gas industry operates with fairly regular cycles, even though 1980-1986 fits the 5-8-year pattern. That conclusion suggests there may be other issues unique to the oil and gas business or to the overall economy, that have influenced the pace and cyclicality of oil prices since we entered the twenty-first century.

An alternative scenario is that 1986-1998 was the oil industry’s historical aberration once it entered a free-market era. Up until the early 1970s, the Texas Railroad Commission managed surplus oil production to control pricing. Once the U.S. exhausted its ability to be the marginal supplier, pricing power shifted to OPEC. The organization had been formed in 1960 to fight oil price reductions by the international oil companies operating country concessions. A second factor in oil pricing was the closing of the gold window. In 1973, President Richard Nixon ended the ability of countries holding U.S. dollars to exchange them for gold, which contributed to rising interest rates, greater inflation, and depreciation of the U.S. dollar’s value. These conditions strengthened the case for higher oil prices.

Exhibit 3. Trying To Establish The History Of Oil Cycles

Source: EIA, PPHB

The idea that the 2020 and 2014-2016 cycles are merely extensions of a longer industry cycle that began in 2008 raises other questions. It suggests that the oil price spikes that dominated the 1970s and the 2000s were aberrations, and should have been viewed as warning signs. Maybe it means we should consider the 2009-2014 high-oil price period as an aberration and, thus, should view this downturn as beginning in 2014. If so, then we are left to ponder whether this cycle will last as long as the 20 years of the 1980 cycle. Should we be thinking about an oil cycle that doesn’t end until the mid-2030s? That is certainly a depressing thought.

The optimists in the industry, and among Wall Street analysts and investors, believe that the under-investment in oil and gas exploration and development over the past 3-5 years means we are destined to revisit $100 a barrel oil prices again, maybe as soon as 2021-2022. If that happens, does it mark the end of the current downturn or just a reflection of increased oil price volatility?

In trying to answer the question about short-term versus long-term oil industry cycles, it helps to consider the views of one of the key players in the business and an astute industry strategist. We are referring to Andrew Gould, the former Chairman and CEO of Schlumberger, whose tenure ended at the top of the last boom, but whose career allowed him to play a key role in reshaping the company and its strategy during many challenging environments.

Let’s review some of Mr. Gould’s bona fides. His education involved a degree in Economic History from the University of Wales, Cardiff. He served as the CEO of Schlumberger from February 2003 to August 2011, and continued as Chairman until the annual shareholder meeting the following April. WTI averaged over $103 per barrel that month, after peaking the prior month above $106. Timing is everything!

His 36-year career at Schlumberger began in the finance group, after he had worked initially for Ernst & Young, a major global accounting firm. He rose through the finance group ranks, serving as an internal auditor, controller, treasurer and vice-president of finance of various Schlumberger divisions around the world. In 1991, Mr. Gould became vice-president of operations of Sedco Forex, the company’s contract drilling group, rising to its presidency in 1993. His tenure at the contract drilling group extended to 1998, at which point significant restructuring of the global oil and gas and oilfield service industries commenced. He then moved to the presidency of the Wireline & Testing division, before moving up to become the president of the Oilfield Services Products group. From there he stepped up to executive vice president of the entire Oilfield Services business of Schlumberger, before becoming president and chief operating officer and then chairman and CEO.

During his tenure at the top of Schlumberger, Mr. Gould was acknowledged as the leading light of the industry in dealing with customers and investors, setting the tone in discussions about activity levels and the direction of the business. When he assumed the CEO role in 2003, he moved quickly to lead a renaissance of the company, which included boosting financial returns, improving the balance sheet, and realigning the firm’s strategic focus on its oilfield services business, the foundation of the 80-year-old company. In two years under Mr. Gould’s direction, Schlumberger boosted its return on capital to 13% from 7%, cut its net debt to $2 billion from over $4 billion, and divested non-core assets such as Sema, Smart Cards and Electricity Metering, raising in excess of $2 billion. During this time, Schlumberger’s oilfield revenues and earnings per share increased by 9% and 28%, respectively.

Mr. Gould set out his strategic plan for Schlumberger in a speech on September 2, 2003, to analysts at the Lehman Brothers CEO Energy/Power Conference. He told the audience: “What is sure is that if the world is going to have a reasonably priced energy supply to continue to fuel economic growth, we need to rapidly adapt to more volatile times, risk and reward opportunities will therefore abound. In these circumstances, I am confident that in the coming decades, Schlumberger will be a major beneficiary in the renewed investment that will be required to guarantee our energy future.”

Given Mr. Gould’s record at Schlumberger, although one cannot underestimate the strength of its franchise, something we always referred to as the company having a printing press in the basement, his observations about the financial history of the oilfield industry warrant attention. The wireline technology developed by the Schlumberger brothers in the 1920s, and controlled by them, as opposed to almost every other oilfield technology, earned the company huge returns. Those profits enabled Schlumberger to deal with some horrendously poor investment returns due to acquisition decisions in the 1970s and 1980s, often driven by the need to continue to curry the support of French political leaders.

A few months after leaving Schlumberger, Mr. Gould spoke at the Energy Summit at the British Business Embassy in 2012. We also have the benefit of his recent discussions with Michelle Foss, Fellow in Energy and Minerals, Center for Energy Studies at Rice University’s Baker Institute for Public Policy. In these various presentations, Mr. Gould provided perspective on the evolution of the global oilfield service industry, and how much the profit cycle and shifting interactions with its customers shaped its growth. As he pointed out, and something not well appreciated, the oilfield service industry was largely a North American affair prior to the oil price shocks of the 1970s. Oil companies maintained their own service divisions – drilling and well completion equipment, as well as well servicing and production maintenance operations. This was largely due to the oilfield service industry having an immature geographical presence in the eastern hemisphere. These divisions were also considered excellent training grounds for oil company petroleum engineers and explorationists.

Exhibit 4. Understanding Drilling Cycle In 1970s-1980s

Source: Baker Hughes, EIA, PPHB

The easiest way to confirm Mr. Gould’s point about the oilfield service industry’s growth is to look at the history of active drilling rigs by geography. The United States’ drilling rig count rose dramatically once the shock of higher oil prices convinced companies to expand their fleets. Exhibit 4 (prior page) also shows how quickly the rig count fell once the oil price dropped. The chart also highlights the relative size of the non-North America market and how slowly it responded to the rise in global oil prices. Activity in those markets didn’t retreat as quickly as North American activity once oil prices peaked in 1980. It wasn’t until after the OPEC battles that resulted in the collapse in oil prices in 1985/86 that international drilling also declined, but at a slower pace than North America, reflecting the long-term nature of contracts outside of North America.

Two additional charts illustrate points made by Mr. Gould: the growth of the service industry and the shift in its emphasis towards more international work. Exhibits 5 and 6 (next page) were taken from data compiled from Offshore Data Services and show the growth in the offshore drilling rig fleets and the number of offshore drilling contractors during 1975-1985. When we focus on the number of drilling contractors, we see that over the decade 1976 to 1985 there were 55 new competitors, representing a 40% increase. Over 70% of the new companies began operating during the first half of that 10-year span.

We also see how during that first phase of the 10-year span, contractor growth was primarily in the U.S., although all sectors grew. The National drilling contractor sector showed the most dramatic increase over the decade, rising by 14 contractors for an 88% growth. Foreign contractors also showed stronger growth over the decade, with U.S. contractors growing the least. In fact, during the second half of that span, the number of offshore drilling contractors shrank, due to consolidation and the exit of oil companies who elected to sell their offshore drilling assets.

Exhibit 5. How Offshore Contractor Population Changed

Source: Offshore Data Services, PPHB

When it comes to the offshore drilling rig fleet, we see, over the period, essentially a doubling in the number of rigs. U.S. contractors added the most with 224 new rigs, a 50% increase in the group’s fleet. Both foreign and national contractors added nearly as many new rigs as U.S. contractors, but the percentage increases were significantly greater at 220% and 402%, respectively. As the data shows, the share of the global offshore rig fleet represented by U.S. contractors fell from 76% at the end of 1975 to only 55% by January 1986. Foreign contractors increased their share from 16% to 25%, but the national group more than doubled its share from 8% to 20%.

Exhibit 6. How Offshore Rig Fleet Changed 1975-1986

Source: Offshore Data Services, PPHB

While the dynamics of the oilfield service industry were influenced initially by the 1970s oil price shocks and a shift in focus to the eastern hemisphere, there was another change in industry dynamics. It involved the role of technology, a subject key to Schlumberger’s growth. Following the 1980s oil price peak and initial downturn, the oil companies began divesting their oilfield service divisions in what was their first cost-cutting effort. In turn, this drove oilfield service companies to start spending on R&D to improve their relative competitive positions. After the 1986 oil price collapse, activity was down for a decade. R&D was directed to reducing finding and development costs. This led to oil companies closing whole departments and laboratories, as well as selling their drilling rigs and seismic vessels that they had built to ensure they always had access to supply.

As the oil companies began exiting their service operations and relying more and more on service companies, there was a broad push for service companies to expand their technology offerings. In some cases, the service companies were pushed to invest more in technology as the oil companies looked for greater integration at the level of the service companies to reduce costs. Mr. Gould pointed to Shell’s “Drilling in the Nineties” and BP’s “Partners for Profits,” both aimed at reducing drilling costs in the North Sea through greater integration of the service providers. He also commented that for several years during the 2000s “Mexico’s PEMEX was by far Schlumberger’s largest customer due to the appetite for fully integrated projects.”

Technology also proved critical for the development and success of both national oil companies and independent producers. As Mr. Gould explained, the nationalizations of major oil company operations in many foreign locations led to the national oil companies being forced to rely on the service industry for technology, which they previously obtained indirectly from their operator partners. Additionally, a new generation of national oil companies understood that technical skills were essential to their future and actively cooperated with the service industry to obtain technology. The ability to purchase technology from service companies has also enabled the independents to play a greater role in the evolving industry.

Shifting to the 2000s, Mr. Gould discussed the unprecedented growth in activity, driven by the rapid demand growth from China, and the increasingly challenged global resource base. Increases in activity included a surge in offshore drilling rig construction. Prior to 2015, there were 50-100 new offshore rigs under construction per year. Such growth had not been seen since the 1980s.

Exhibit 7. How Offshore Rig Fleet Grew Through History

Source: Offshore Data Services, PPHB

He highlighted how the low investment during the 1986-1999 period contributed to the explosion in exploration and production capital expenditures. In the four years prior to the 2008-2009 recession, E&P spending had more than doubled. The emergence of the U.S. oil shale plays added $200 billion a year in domestic onshore industry spending. Prior to this downturn, the International Energy Agency (IEA) estimated that upstream oil spending would need to total more than $500 billion a year between 2018 and 2030. The IEA also said that about $400 billion a year would be needed for natural gas infrastructure and supply over the same period.

To demonstrate the magnitude of the spending, Mr. Gould cited data from Schlumberger’s Business Consulting Group. Between 2000 and 2011, capital spending grew at a compound annual rate of 14%. This produced both inflation and inefficiencies. The number of mega projects, ones with budgets over $1 billion increased from approximately 50 to 200 in 10 years. The number of operators managing projects over $1 billion increased from 12 to more than 40 in the same period. According to Mr. Gould, “these 200 projects represent 33% of the total spend leaving a long tail, all of which has to be supplied and staffed.”

The challenges of organizing and managing these projects became a serious issue. The fact that there were a number of large cost overruns was not a surprise. But, the size of the cost overruns was.

Mr. Gould said, “25% of projects budgeted at less than $5 billion have a greater than 50% overrun. 35% of projects of over $5 billion have a greater than 50% overrun.”

According to the Schlumberger Business Consulting Group’s survey of customers, the top issues driving the cost overruns were people and organizations. “The difficulty of matching skill sets with project challenges and geography combined with an acute industry skill shortage” was at the heart of the problem. The second contributing factor was “technical challenges;” companies taking on more complex projects. And finally, “governance,” a largely internal management issue was the final factor.

In commenting on these issues, Mr. Gould said, “To summarize, the complexity in capital projects comes from multiple sources, and the impact of this complexity can only be reduced when companies become aware of gaps in their capabilities to manage the complexity through developing experience and continual improvement.” As a result, he suggested that the oil and gas industry should examine how other industries work with their contractors – for example, the automobile industry. After suggesting this course of action, Mr. Gould noted, “The car industry may not appear as a shining example of profitability, but it is one of the best optimizers of supply chain, which was driven by cost concerns.”

Furthermore, Mr. Gould stated, “Very few operators in my experience consult their contractors or service company on what technology they think will be available in seven years-time when they are in the planning stage of their projects.” For such a change to occur, Mr. Gould said it would require “a radical change in contracting philosophy.” Such a change requires “full recognition that the human resource and knowledge within the contracting industry can really add value.”

While the history Mr. Gould recounted was significant for Schlumberger and the industry, it was based on how the evolution from the 1970s to 2012. It ended during the height of the last oil price boom. Since then oil prices have crashed, bounced, crashed again, and are now slowly recovering. Crude oil supplies continued to increase, while demand has been slower to grow. Renewables have been promoted by politicians, governments and utilities, and now are being embraced by some major international oil companies.

In his interviews, Mr. Gould expounded upon the history of oilfield service industry profitability, which is paramount in the minds of industry executives pondering the recovery and what, if any further actions, they should undertake to enhance financial performance. Mr. Gould’s response to a question from Ms. Foss provided insight. She asked whether, when considering the industry’s recovery, anyone has thought about new financial models for oilfield service companies? Mr. Gould’s answer was intriguing:

“Michelle, there are three basic ways that OFS has made good margins in the past and only one of them proved sustainable, at least it was until the recently departed CEO of Schlumberger decided to indebt the company to invest in E&P.” Ouch!

The three times Mr. Gould referenced were described thusly:

“Method 1: Periods when short-term demand for OFS exceeded supply and services were rationed to customers through pricing.”

“Method 2: Early mover in geographical presence and political risk taking.”

“Method 3: Sustained technology lead and creating value for the industry.”

Mr. Gould presented examples of each method. In the case of Method 1, when short-term demand exceeded supply, he pointed to two times in his career: 1) the few years following the departure of the Shah of Iran in the late 1970s; and 2) 2005-2006 when China’s oil demand surged. In both cases, there was a surge in activity due to oil supply shortages – the loss of Iran’s oil output and China’s surprising demand growth as it embarked on massive infrastructure investment as it readied its country for the upcoming Olympics. In both cases, as the service industry scrambled to meet the increase in activity, equipment and engineers were rationed through price, which led to healthy profit margins.

In Method 2, which involved geographical presence and political risk taking, there were two periods. Again, the years immediately after the Shah’s departure. In that case, in Asia, the only real oilfield service presence was represented by Schlumberger and Halliburton, who dominated their respective core product lines and commanded huge market shares, and thus pricing power. The second time was after the opening of the Soviet Union. In 1997, the ruble collapsed and state oil and gas assets were vacuumed up by the first generation of Oligarchs. They then turned to western service companies to try to improve their performance. In Schlumberger’s case, it advanced $200 million to Mikhail Khodorkovsky of Yukos, which he was to reimburse at the end of the first year. Twelve years later, Schlumberger had a $2 billion business in Russia, which Mr. Gould indicated remained one of the most profitable geographies in the company.

The greatest challenge is Method 3, which involves a sustained technology lead that can help create value for the customers. As Mr. Gould put it, “there are, in fact, very few products or product lines in oilfield services that contain technology that can make material differences to the oil company performance.” As he put it, much of what the oilfield service industry does is “fairly complex civil engineering or industrial construction.” In his view, “the only product lines that add true value are those that enable the oil companies to find, understand, plan and ensure that the maximum of the discovered hydrocarbon is extracted from the subsurface.” The product lines he singled out included some seismic, open hole wireline logging, directional drilling combined with logging-while-drilling, geosteering and rock and fluid analysis. He also would include some subsea equipment, due to the demand for its reliability equaling that of space travel.

In looking at how technology helps open up new exploration and development basins with challenging geophysical properties, Mr. Gould cited the deep and hot, offshore, and particularly deepwater markets where the technological services needed are so vital that they have relative price elasticity. These profit opportunities contrast with shale, which Mr. Gould finds to be a “fool’s errand.” As he pointed out, shale possesses none of the three methods in which oilfield service companies are able to make money. In his view, “the method of exploitation required very little technology, let alone unique technology.” He went on to describe the history of long horizontal drilling and massive hydraulic fracturing. In his view, the improvements in the process of tapping shale oil and gas has involved incremental improvements in operational efficiency and reducing the cost of fracturing, by using slick water. Is there hope for shale?

In Mr. Gould’s view:

“The North American Shale ‘revolution’ has not yet achieved a level of operational and financial stability that will allow it to be a responsible part of the world supply system. It will remain volatile until the necessary elimination of the marginal players and accumulation of debt has taken place. What is true of the operators is true for the service industry, and in the next phase of shale, the use of technology and the concentration of more responsible operators will lead to improved market conditions for the remaining service players. In the meantime, we will see production declines and financial distress again.”

While offering hope for the oilfield service industry working in the shale basins, his outlook for what has to change signals there is a long road ahead for these basins to become profitable. Erasing the debt of companies and eliminating marginal players to reduce capacity are not easy steps. In fact, most of the bankruptcies so far reflect reorganizations of balance sheets, in many cases still leaving large amounts of debt, and less about restructuring the industry, i.e., eliminating equipment and companies to improve the competitiveness of markets.

A report by the oilfield analysts of Wall Street broker Bernstein focused on the industry’s labor situation and what it portends for the entire oil and gas industry, highlighted some of Mr. Gould’s points. We are going to borrow several charts from that report that show the financial deterioration for the oilfield service sector since the mid-2000s. Several of these charts demonstrate how pricing power and profits shifted from the service sector to the producer sector. One reason for that shift was the rush of new capital into the service industry to capitalize on expectations that the 2012-2014 boom would continue and drive activity substantially higher. Several of the charts contain forecasts for the particular data series. We are not commenting on the forecasts, but rather want readers to focus on the historical data presented.

One of the most telling charts shows an index of revenue and EBITDA per employee (head) from 1998 to 2019. What the index shows is that during the Expansion Cycle, profitability per employee grew rapidly, as oil prices rose in response to the supply shortages driven by China’s economic expansion. That was one of the periods Mr. Gould cited for the service industry’s profitability improvement. Although revenue per employee remained essentially flat from 2008 through 2018, profitability was eroded quickly, largely because the service industry invested in additional equipment and the number of competitors expanded, increasing competition. That competition resulted in less pricing and return-on-investment discipline. The lower pricing is demonstrated by the fact that increased activity during the boom and recession necessitated adding employees, but did not improve profitability.

Exhibit 8. History Of Oilfield Service Performance

Source: Bernstein

A second chart shows how the natural profitability that should accrue to the oilfield service companies has been coopted by the customers. Again, this reflects the inability of the service industry to manage pricing and capital allocation during a period when capital was flooding the industry to expand capacity for meeting activity growth and projections for even greater growth.

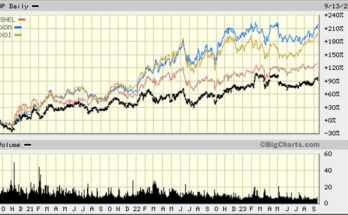

Exhibit 9. Producers Have Profited While OFS Were Hurt

Source: Bernstein

Two additional charts from the Bernstein report show what has happened to pricing in two important oilfield sectors – offshore drilling and hydraulic fracturing. These two product lines have been important drivers of oilfield activity and U.S. oil production growth. As we saw in Exhibit 9, the oilfield service industry has contributed to a dramatic increase in oil and gas output. We should not lose sight of the impact this production growth played in the economic growth of the United States in recent years and the geopolitical leverage it gave the country.

Exhibit 10. Offshore Sector Is Being Hurt By Too Many Rigs

Source: Bernstein

Exhibit 11. Pressure Pumping Sector Is Struggling

Source: Bernstein

It is difficult to imagine either of the two important sectors reversing current trends until excess capacity is removed through scrapping rigs and pumping horsepower. The number of service companies in each sector that have entered, or are contemplating entering, bankruptcy offers hope that the industry is closer to the days of equipment supply and demand balance, or possibly even a shortage. As of now, we don’t know whether the reduced debt loads of restructured companies will need to be reduced further, thereby prolonging the pain. Possibly new company shareholders following bankruptcies will have a greater willingness to scrap equipment. These questions play into final thoughts from Mr. Gould.

In concluding his interview with Ms. Foss, Mr. Gould offered two observations that seem obvious but appear to have been ignored. “OFS companies can only survive the cycle with fortress balance sheets,” he said, pointing to the history and philosophy of the Schlumberger founding family. The challenges the company is dealing with now are a reflection of the deviation from the philosophy by Mr. Gould’s immediate successor as CEO of Schlumberger.

The second guiding principle he offered was: “There has never been a shortage of [oil] supply, only dislocations in its availability. The industry has never learned that what goes up in cyclical business[es] will come down and has never properly protected itself against its own eternal optimism.”

What is the significance of Mr. Gould’s conclusions about the cyclicality of the oilfield service industry, and especially the current cycle? As Mr. Wicklund said, which we quoted earlier, no one saw the current downturn. We would ask whether no one saw it coming because no one was paying attention? Maybe everyone was blinded by the glow of the shale revolution? Exhibit 12 presents an interesting perspective on what was happening prior to the 2014 OPEC meeting, and then the industry’s reaction. The reaction to the 2020 downturn has been very different.

Exhibit 12. Was No One Watching The Market In 2014?

Source: EIA, PPHB

As the chart shows, from the June 20, 2014, oil price peak to the date of the OPEC meeting, the price declined 32%. Over the same period, the total and oil drilling rig counts increased by 59 and 27 rigs, respectively. The fall in oil prices drove the smaller members of OPEC to call on Saudi Arabia to cut production to support prices. Saudi Arabia, instead, decided to go after its lost market share, and thereby defied the calls and kept its production up. It took a while for the impact of Saudi Arabia’s decision to register with industry executives. That may have been partly because they expected OPEC to “get its act” together and restore pricing support. Lower-for-longer only became obvious a couple of months later.

In the current downturn, the industry reacted faster to the oil war erupting between Russia and Saudi Arabia. The faster reaction was probably helped by the onset of the Covid-19 pandemic that was shutting down economies around the world and in various U.S. states. There had also been extensive posturing by the key parties heading into the March 5, 2020, OPEC meeting, so executives were alert to the possibility of what happened, actually happening.

In our view, this spring’s oil supply and oil demand shocks were comparable to the 1986 oil price collapse, and makes what we are experiencing now part of a longer cycle. From the 1980 price peak, and the subsequent 1986 price collapse, the recovery needed years to recover – 20 years, in fact. The start of the next cycle began in the late 1990s when the oil and oilfield service industries went through a massive restructuring. To date, the industry restructurings seem more like those experienced during the second half of the 1980s when oil industry and service company bankruptcies exploded. Are we looking at a 20-year total cycle as in the 1980s? If so, we have years of rough times ahead for this industry. While substantial debt is being wiped out in the reorganizations, many of them retain meaningful chunks of debt on company balance sheets, likely meaning further indigestion before a complete recovery can be achieved. Many companies will revisit bankruptcy, unless there is a massive uptick in activity. With oil companies and banks reducing their long-term oil price forecasts, and the growing push for renewables as key parts of government economic recovery plans, the oil and oilfield service industries of the future will be smaller, but hopefully solidly profitable. The journey to profitability is just beginning. How long it takes is unknown, and it will be bumpy.

Hydrogen: Miracle Clean Fuel, Or A Financial Disaster? (Top)

Hydrogen – the chemical element with the symbol H and atomic number 1 – is the lightest element in the periodic table and the most abundant chemical substance in the universe. Hydrogen in Greek means “water-former,” which is what happens when the gas is burned, and which was first recognized by scientist Henry Cavendish in 1766. The element is now being touted as the key to our clean energy future. Its importance comes from it being a gas that can utilize the existing natural gas pipeline infrastructure, and comes in various forms – gray, brown, blue and green. The latter two colors are in keeping with the image of clean energy. What hasn’t been resolved is how hydrogen can fulfill its mandate in a cost-effective manner.

Exhibit 13. Hydrogen Comes In Multiple Colors

Source: Cedigaz

Hydrogen is being presented as the critical fuel source if net-zero carbon emission mandates by governments around the world are to be met. Critical to hydrogen’s success is its ability to utilize existing energy facilities. That still presents some challenges as hydrogen is notoriously volatile, and in liquid form must be cooled to temperatures twice as cold as for liquefied natural gas (LNG), necessitating rebuilding many storage and transportation assets. Initially, given high transportation costs, the economics of hydrogen production favor on-site production. Tests of various approaches to producing, storing and transporting hydrogen are beginning, but little is known about their cost and/or operational challenges, even though hydrogen has been used for decades in various industrial applications worldwide.

In the United Kingdom, the country’s energy infrastructure operator – National Grid Electricity System Operator (ESO) – issued a 124-page report outlining the nation’s future energy mix as it strives to meet the 2050 net-zero carbon emissions mandate. Hydrogen “could be the solution to many of the hardest parts of the transition to net-zero”, National Grid says, particularly in long-distance freight, shipping and heavy industry. However, the report never addresses the cost of hydrogen in any of the four future energy scenarios it presented for 2020 (FES 2020).

The FES 2020 report continues the U.K. utility company’s study of future energy markets that it has undertaken every year since at least 2012. The report creates multiple scenarios. As the company has done for many years, it developed scenarios based on its own modeling and in consultation with the energy community. This year, there are four new scenarios – Leading the Way, Consumer Transformation, System Transformation, and Steady Progression. A summary chart in the report shows how the four scenarios perform in meeting the U.K.’s legally-mandated net-zero carbon emissions target of 2050. Three scenarios meet that goal with Leading the Way achieving it by 2048, two years early.

Exhibit 14. Three Of Four Scenarios Reach Net-Zero

Source: FES 2020

The headline conclusions from the FES 2020 scenarios, presented in the Executive Summary section, are listed in Exhibit 15 (next page). The fact that scenarios show net-zero emissions can be achieved, the urgency of what needs to occur to make it happen becomes uppermost in the thinking, and importantly, in the actions of utility companies, consumers and regulators. Because hydrogen and carbon capture technologies are critical to meeting the net-zero emissions target, industrial-scale projects need to begin immediately to demonstrate their feasibility. Therein lies a potential flaw in these scenarios. What if these demonstration projects fail, or fall short of the successes assumed? Since costs are not considered in the scenarios, the projects may succeed, but at extremely high costs rendering them uneconomic for deployment, but they can still be declared successes.

Exhibit 15. Key Observations From Energy Scenarios

Source: FES 2020

The National Grid ESO report is being widely hailed for its progress in addressing carbon emissions. James Brabben, Wholesale Manager at Cornwall Insight, an energy consulting firm, said, "More so than previous years, FES 2020 strikes a more confident tone on the practicalities of achieving carbon reductions. A ramp-up in wind and solar deployment, large-scale hydrogen and CCUS build-out and the digitalization and transparent use of customer data is prevalent across scenarios. Hydrogen is for the first time seen as a front-running technology for heating use, some transport sectors and electricity system flexibility.” That latter observation is key to a discussion about how Europe is embracing hydrogen as the clean gas, as it strategizes over meeting net-zero carbon policies.

National Grid ESO set the stage for its report by setting forth how it approached establishing its scenarios. The report stated: “This year FES uses the lenses of decarbonization and societal change to develop possible pathways for what the future of energy may be and how we could decarbonize our energy system.” With these two lenses as a guide, the report began with a discussion of the changing energy mix from the consumer perspective. The report pointed out: “In a net zero world, fossil fuels need to be replaced by electricity and hydrogen for transport and heating. At the same time, consumers must be willing to change how and when they use energy and be prepared to change to more energy efficient technologies.” In other words, get ready to live differently than you have up to now, but we really can’t tell you the extent of those sacrifices, nor how disruptive they will prove to be for your lives, let alone what the cost will be.

Of the four scenarios, Leading the Way reaches net-zero emissions by 2048, which National Grid ESO describes as the “fastest credible decarbonization” pathway. The societal changes include shifts away from private car use and major improvements in home energy efficiency. They don’t tackle diet or land use, which would involve significant changes to the agricultural sector.

The System Transformation scenario employs the largest amount of hydrogen, which is utilized for home heating, industrial use and vehicles. A key benefit of this scenario is that it is less disruptive of peoples’ lives. For example, it involves less effort to improve home insulation and smaller changes in transportation behavior. These are great selling points for getting people to commit to hydrogen.

Exhibit 16. The Significant Role Of Hydrogen In U.K. Energy

Source: FES 2020

The schematic of the flow of fuels and end market uses demonstrates how significant a role hydrogen will play in this scenario’s future energy mix. What is also noteworthy is that natural gas plays a major role in the energy mix throughout the forecast period. Natural gas consumption remains relatively constant at just 16% below 2019 use. This is because natural gas is the primary fuel for producing hydrogen! The greatest challenge in relying on hydrogen, however, is the hefty efficiency losses. Thus, the scenario dictates that hydrogen should be used in applications where there are minimal alternative fuel options, such as heavy-duty trucking, shipping and, in some cases, home heating and heavy manufacturing industries. While these applications will produce clean fuel, it will be more expensive and probably less efficient, further inflating the cost to users.

The role of natural gas in this scenario is significant, as shown in Exhibit 16 (prior page). Almost all the hydrogen is to come from natural gas reforming, with only a small amount from electrolysis, which is the most expensive process. It is envisioned that this latter supply will target markets with few alternative fuel options. Hydrogen produced by electrolysis would utilize excess electricity from renewables, which has little value, to reduce the cost of producing the fuel. This fuel supply will be important for increasing the flexibility in energy markets envisioned and needed in the scenarios. Capacity to produce hydrogen by electrolysis is projected to increase from less than 1 gigawatt (GW) today to as much as 10GW by 2035 and 73GW by 2050. The higher number would mean less natural gas needed to produce hydrogen.

As the volume of natural gas needed by the U.K. remains high, the more important consideration is the country’s dependence on imported supply. This dependency in 2020 is estimated at 55%, but rises steadily to 98% in 2048. This might be an economic vulnerability that U.K. residents will not be willing to assume if they fully appreciate and understand the implications and risks.

Exhibit 17. Imported Natural Gas Will Increase U.K. Risk

Source: FES 2020

Another key supply source in all the scenarios is the reliance on electrification of the transport sector in decarbonizing the economy. By 2040-2050, there are projected to be around 30 million electric vehicles (EV), compared to about 100,000 at the close of 2019. At the present time, the U.K. has about 32 million vehicles on its roads. Every scenario reaches a total of 30 million EVs and then remains at that level through 2050. The Leading the Way scenario sees the number of EVs declining from 30 million during 2040-2050, as autonomous vehicles and the abandonment of private car ownership in favor of ride-hailing and public transportation become greater forces in the transportation sector.

National Grid ESO has been a strong proponent of “vehicle to grid” (V2G), as a way to balance the electricity grid. They see V2G supplying as much as 38GW of electricity supply by 2050, during periods of peak demand. That would represent nearly two-thirds of the current peak demand of 58GW.

Exhibit 18. How EVs Will Come To Rule The U.K. Roads

Source: FES 2020

The U.K., like its neighbors on the continent, is starting down a road to net-zero carbon emissions with high hopes its plans will work. It will depend on whether the utilities and politicians can convince the residents that radically changing their existing lifestyles and behaviors is necessary and desirable in order to curb climate change. Replying on unproven technologies, or ones that have yet to be done at scale, is a huge gamble. Moreover, the inability, or unwillingness, to explain what the cost of this new energy world will be for residents is setting up the possibility of a serious political revolt. We will be watching closely from across the pond.

Do Offshore Wind Economics Meet Lower Cost Claims? (Top)

In the United States, efforts to exploit the nation’s offshore wind resources are moving ahead rapidly. The first offshore wind farm, a five-turbine, 30-megawatt (MW) project constructed four miles off the coast of Block Island, commenced operation in December 2016. That wind farm was located in Rhode Island state waters under policies that facilitated its construction. Recently, two 6-MW wind turbines were installed in federal waters off the coast of Virginia. These turbines will provide information to help their owner, Dominion Energy, manage its planned huge offshore wind farm to be constructed over the next five years in two phases. Each phase will total 880 MWs and require over 70 turbines. These wind farms are expected to begin construction in 2024, following the approval of their plan of development to be presented to regulators in late 2022. The first phase anticipates beginning operation in 2025 followed by the second in 2026.

Off the coast of Massachusetts, Vineyard Wind is planning an 800-MW, 84-turbine wind farm 35 miles south of Martha’s Vineyard. This project originally envisioned commencing operations in 2022, but given an extended environmental review, the Bureau of Ocean Energy Management (BOEM) is now scheduled to render a verdict on the application in December. Regardless of the decision about the Final Environmental Impact Statement (FEIS), we fully anticipate lawsuits over the approval process, which could push the start-up off for another 1-3 years.

As the 45-day comment period for BOEM’s updated environmental review was drawing to a close, we received an email from the Union of Concerned Scientists (UCS) imploring us to: “Write today and tell federal regulators you support the future of offshore energy.” The final battle over the government’s study was its position on the layout of the wind turbines. The plan originally envisioned turbines being arranged in a one-nautical-mile grid, an option that still remains. This layout is designed to permit fisherman to operate within the confines of the wind farm and for ships to transit.

The Responsible Offshore Development Alliance, a coalition of commercial fishing groups, has pushed for another layout option involving several 4-mile-wide transit fairways. If this option is adopted, the size of the wind farm would shrink, potentially rendering the wind farm uneconomic, grounds for the owners to sue. The U.S. Coast Guard okayed the grid layout, but its study has been criticized as inadequate. It relied on Automatic Identification System (AIS) data, a system that allows other vessels in the immediate area to be seen by all vessels to avoid collisions. The problem is that very few fishing vessels have or use AIS. This raises questions about whether the Coast Guard is underestimating the number and operational patterns of the vessels that actually work the fishing banks where the wind farm is to be installed. You can see the legal split generating lawsuits regardless of the layout option BOEM picks.

One paragraph in the email from the UCS caught our attention. It stated:

“Offshore wind is well positioned to be a major source of clean energy for the United States. The wind resources off our coasts are some of the most powerful in the world, and close to where the power is needed. Many states have laid out ambitious goals for harnessing offshore wind power. And its cost has fallen dramatically in recent years.”

There is no question that the potential offshore wind resource is huge. That is well documented by scientific studies. Clearly, the Atlantic Ocean wind resource is close to the major population centers located along the East Coast, so getting them power is an admirable objective. Whether that power would be cheaper than customers are already paying is uncertain, although it is assumed to be by its promoters, besides being cleaner. Those assumptions are key in driving the construction of offshore wind farms to help meet the net-zero carbon emissions mandates of the coastal states. The Block Island wind farm has a much higher electricity cost (27-cents per kilowatt-hour versus the 19-cents/kWh) than charged on the mainland. In addition, the offshore electricity price escalates by 3.5% every year of the 20-year contract life, but not the onshore price. The higher offshore price was rationalized by it competing with electricity from diesel-fired generators on the island whose output cost at the time was in excess of 50-cents/kWh. The wind farm project also included installation of a power cable to shore that would take any surplus power, but also enables the island to always have electricity from shore if the wind farm fails to generate enough.

A quote from an article on e360.yale.edu highlighted the potential growth of offshore wind on the East Coast. It stated:

“According to the U.S. Department of Energy, more than 25 offshore wind projects with a generating capacity of 24 gigawatts are now being planned, mainly off the U.S. Northeast and mid-Atlantic coasts. And although some of these projects may not be built, and only one commercial offshore wind farm has actually been constructed —the tiny, five-turbine “Block Island Wind” project off Rhode Island — analysts say that U.S. offshore wind is expected to enjoy significant growth in the coming decade.”

Given all this activity, we wondered if the assumption about falling costs was actually true, especially given the surge in offshore wind in Europe. As we contemplated this question, we were alerted by a headline from The Independent newspaper in the U.K. that offered hope for some data on wind farm costs. The headline read: “Climate crisis: Offshore wind power ‘so cheap it could return money to consumers.’” Was this negative pricing, which we hear about repeatedly with wind energy? How was that benefitting customers? Actually, it was a statement that the subsidies the U.K. government is paying for offshore wind would decline in the future due to lower cost wind power. In other words, the government wouldn’t be providing as large a subsidy for the future wind power, therefore the monthly charge on customer bills would decline. As with all promises of largess due to government prescient investments, we suggest U.K. consumers hold on to their wallets.

The article was based on a paper recently published in Nature Energy by researchers at the Imperial College London’s Centre for Environmental Policy, jointly with institutions in Denmark, Belgium, the Netherlands and Germany, along with comments to the reporter from the paper’s authors. Lead researcher Dr Malte Jansen, from the Centre for Environmental Policy at Imperial College, said:

“Offshore wind power will soon be so cheap to produce that it will undercut fossil-fueled power stations and may be the cheapest form of energy for the UK. Energy subsidies used to push up energy bills, but within a few years, cheap renewable energy will see them brought down for the first time. This is an astonishing development.”

Exhibit 19. How U.S. Power Market Has Changed Recently

Source: Ofgem, PPHB

The U.K.’s power market has changed materially in recent years. As Exhibit 19 shows, since 2012, coal has lost most of its market, while natural gas, wind and solar grew. The most recent surge in wind and solar has cut into nuclear energy’s contribution, as well as that of natural gas. The first quarter of 2020 is the initial quantification of the offshore wind and solar contribution. It represented 47% of the total wind and solar power category. Based on the number of offshore wind farms scheduled for completion or planned over the next five years, this share will rise substantially.

That is why the newspaper article’s headline, with its promise of a shrinking renewables subsidy, sparked our interest. The shrinking subsidies are arguably due to new offshore wind farms costing less to construct. Cheaper power needs less in subsidies – assuming the study is right. An analysis by other researchers showed that the assumption of dramatic declines in offshore wind farm construction costs is wrong, meaning government subsidies will continue rising, along with customer bills.

According to the U.K. government’s budget projections for environmental levies – the amount of money paid to renewable fuel providers ‒ will rise steadily for the next five years. The data was in the March 2020 update from the U.K. Office for Budget Responsibility.

Exhibit 20. Forecasts Call For Environment Fees To Rise

Source: Office for Budget Responsibility

The critique we referenced above was entitled “OFFSHORE WIND STRIKE PRICES – Behind the headlines,” and published shortly after the Imperial College London paper. The critique was prepared by three highly recognized energy researchers and published by The Global Warming Policy Foundation. The paper’s summary points to other explanations for lower prices in recent offshore wind power contracts than lower capital costs. In fact, bidders may be gaming the market as developers seek to win projects and will deal with profitability later, if at all. The summary stated:

“Because the successful bid prices (£57.50/MWh and £74.75/MWh, in 2012 prices, $75.43/MWh and $98.06/MWh, respectively) for offshore wind in the second round of competition for UK renewable electricity Feedin Tariffs with Contracts for Difference (FiTs CfDs) are very significantly lower than those awarded in 2015 (£114–£150/MWh in 2012 prices, $150/MWh and $197/MWh, respectively) it has been widely assumed that the underlying costs of offshore wind are falling, and that the CfD prices indicate a sudden paradigm shift for the technology. However, statistical analysis of the data available, covering 86 offshore wind farms, suggests that the capital cost of offshore wind (£/MW installed) is not in fact falling, since the extra costs of necessarily moving into deeper water are offsetting a real but modest rate of technological progress. The successful projects in the second round are almost certainly not viable at the low CfD prices offered, and these bids therefore must have other explanations. We infer that developers see the CfD as a low-cost, no-penalty option for future development, and that, because the contract is easily broken once the windfarm has been built, they regard the price as a minimum not a ceiling. Should the market price rise above the contracted price, because of rising fossil fuel costs or a carbon tax, they would cancel the CfD contract and take the higher price that would become available. On the other hand, if there is no significant probability of that elevated market price, these sites are very unlikely to be built. Contrary to media exaggerations, the low CfD prices are commercial speculation, not the dawn of a new age for offshore wind and renewables.”

The authors of the critique point to the sloppiness of the media by not focusing appropriately on the difference in the timing of the prices – 2012 versus 2017, and for some new projects what their costs might be in 2024-2025. They ask why the media hasn’t questioned whether it is possible for such a dramatic decline in pricing in such a short time span. But, as they also point out, there is little data on offshore wind farm capital costs. In their critique, they relied on three databases, one assembled from public reports by companies. Another database from an “EU-funded study by the FOWIND consortium (Facilitating Offshore Wind in India) covering various European sites, and prepared under the auspices of the Global European Wind Energy Council.” In that study, the authors, who examined a smaller database and over a shorter time period, noted, “The broad trend in the development of Capex since the early days of offshore wind technology in the early 1990s is contrary to any expectation of conventional industrial maturation. Learning or experience curve theory would predict reducing costs with time, through the combined impact of innovation, learning effects and economies of scale. The historical reality has been dramatically different . . .with Capex increasing . . . .”

The critique paper utilized a larger database and over a longer time period that they created. They produced a scatter plot of the data for offshore wind farms by water depth and year of construction.

Exhibit 21 Offshore Wind Farms Show Rising Costs

Source: GWPF

When the capital cost for a standard wind farm – capacity 600 MW, built in North Sea waters with a depth of 40 meters (132 feet) – was analyzed, the authors found unit costs in 2012 dollars rose at a 6.1% annual rate from 2005 to 2013. Since then, the cost has declined at a 4% annual rate. The authors said this decline “is a real but modest rate of technological improvement, and to be expected.”

Exhibit 22. Rising Wind Farm Costs Are Now In Decline

Source: GWPF

The question is what may be going on within the cost data. They found that wind farm capacity and distance from short had little or no effect on unit costs. There also seemed to be no indication that increasing the size of turbines actually reduced the capital cost of new installations. The authors wondered whether the rising cost trend in the early years was due to the extra costs of upgrading 2-3 MW onshore turbines for offshore use, at least in deeper waters.

The authors then looked at what has happening to the cost of standardized wind farms built in 2016 when water depth increased. The data showed a steadily rising cost trend. As a result, the authors concluded that the decline in standardized wind farm costs since 2013 has been somewhat offset by the move to deeper waters and larger wind farms, thus more infrastructure investment. They point out that U.K. offshore wind farms completed between 2000 and 2009 were in an average water depth of 15 meters (45.5 feet), increasing to 21 meters (69.2 feet) for 2009-2014, and is set to double to 42 meters (138.6 feet) for ones coming into service after 2020. This trend has been a counter to the cost decline in recent years.

Exhibit 23. Deeper Water Translates Into Higher Wind Cost

Source: GWPF

After assessing the data, the trends suggested to the authors that the recent auction prices are assuming unsupportable trends, or bidders are purely speculating on rising power prices. There are several possible explanations. First, bidders believe equity and debt investors will accept lower rates of return on their investments. As the authors calculated, for these projects to be successful at the pricing terms and projected capital investment criteria, rates of return need to be below 2%. They question whether investors would accept such low returns for the risk of these projects. This return issue is associated with the entire renewable energy space, as BP plc cited in its recent earnings report. BP forecasts a return on average capital employed of 8% to 10% for renewable energy investments compared to 12% to 14% for its hydrocarbon investments, and 15% to 20% for its convenience stores and mobility business. When BP CEO Bernard Looney presented his initial perspective on energy diversification earlier this year, he highlighted that pension investors (those counting on dividends in retirement) would have to accept a lower return from their BP investment if the current renewables return environment continued and the company devoted more capital to the business. This may be a hidden pitfall for investors if they fail to understand the low returns of renewable energy investments.

The authors’ second explanation is that bidders believe the cost of building new offshore wind farms after 2020 will be less than 40% of the projected figures that came from their analysis of cost trends. They see no evidence of that belief, based on public statements made by developers, which tend to be optimistic in any case.

The third possible explanation, and the one favored by the authors, is that bidders bid low and uneconomic prices in order to make sure of obtaining a CfD. They see this as a low-cost, no-penalty option, gambling on future market conditions and policies that will generate income above the CfD price. That approach is generally considered speculation, sometimes helpful in markets, but maybe risky for the overall power market. It is important to keep in mind that bidders are not in fact committed to deliver wind power at the prices promised. There are no serious penalties assessed for failure to build the generating capacity promised at the CfD auction. As the authors explained:

“Examination of the relevant sections of these contracts, buried in 540 pages of legalese, reveals that a developer who has built the promised capacity can easily abrogate the contract. If the market price of electricity seems likely to consistently exceed the price set in the CfD then contract holders will be strongly motivated to cancel and pay the relatively small penalty for default. In other words, from the developer’s perspective the CfD price is not a fixed price, but a minimum price. If the market circumstances change and wholesale prices rise, for example because of rising fossil fuel costs or the imposition of a high carbon tax, then they can break the CfD and take advantage of the market rate.”

The people who are truly speculating in the offshore wind farm market are the electricity consumers, although they are ignorant of their gamble. They think they are going to get cheaper power, but it may actually prove to be much more expensive. Additionally, there is the risk the power won’t be there if the wind farms aren’t built on time because prices fail to rise sufficiently to make it attractive for the developers to go ahead with the projects. In that eventuality, power companies will be scrambling to find alternative supplies, which are likely to be much higher cost as suppliers capitalize on the buyers’ desperation to secure electricity at virtually any cost. In recent years, the life of a utility company executive has become much more challenging and stressful. Hopefully, the follies of Europe’s offshore wind industry do not migrate to the U.S. and add to the stress of executives.

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.