- The Rhyme Of Oil History Should Be Heard And Studied – Part 8

- Automobile Revolution’s Impact On Energy Markets

- Ships With Exhaust Scrubbers Are Smiling

- Energy And Tobacco Are Not Equivalent

- Why We Love Texas – From A Friend

Musings From the Oil Patch

February 11, 2020

Allen Brooks

Managing Director

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

The Rhyme Of Oil History Should Be Heard And Studied – Part 8 (Top)

After starting the new decade in the low $60s per barrel, WTI prices are now fighting to stay above $50. The fear of a possible new year’s surprise from North Korea’s President Kim Jong-un and the risk of a retaliation by Iran for the killing of Qasam Soleimani, the Iranian Revolutionary Guard’s top general, lifted oil prices to the highest level since last summer. As no military events occurred, oil prices drifted lower. Now they are fighting to stay above $50 a barrel with the coronavirus raising concerns over China’s oil demand, as its economy and tourism take hits with unknown duration. The uncertainty about the virus’ severity, and its duration, has oil traders growing increasingly concerned about an oil glut depressing prices for much of this year. OPEC’s inability to act to cut output significantly quickly adds to the price uncertainty.

If we ignore current events and focus on energy investor concerns that have been growing over the past two years, little has improved to make them more interested in the sector’s stocks. Investors want radical changes made to the business, before it becomes investable again. They are demanding oil and gas producers demonstrate a commitment to capital discipline, meaning not investing more in the business than can be financed from current company cash flow. That discipline demands that all maintenance capital expenditures necessary to keep production stable must be sustained, and any surplus cash flow be returned to shareholders through dividends or share buybacks. It is also a given that energy investors want producers, and all energy companies for that matter, to reduce their debt to improve future profitability. Shrinking the number of producers is another popular solution advocated for addressing over-levered balance sheets. The bottom line for oil and gas producers is that if you cannot sustain production while living within cash flow, you are liquidating with no value for investors.

Midstream companies by their nature tend to maintain a more leveraged balance sheet, however, investors would like to see them pay down their debt and finance expansion projects from existing cash flow. For the oilfield service industry, the prescription for a return to investor favor requires both deleveraging balance sheets, but more importantly eliminating the surplus equipment overhang depressing service pricing in a low-activity marketplace. A remedy for surplus equipment is to combine companies, enabling the surviving management to scrap equipment inherited in the transaction and for which it has no emotional attachment. Cut it up! That is the solution for excess equipment oilfield service investors are demanding.

While these solutions will likely lead to fewer players, and theoretically improved profitability for the survivors, it is not a given that energy investors will return to the stocks with the same fervor they exhibited in prior cycles. A new ingredient has entered the energy share valuation equation – ESG (environment, social and governance). The ESG movement is stimulating a debate over whether the energy industry is still “investable,” especially as the growing renewables industry offers alternative investment opportunities. While ESG represents a new consideration in the investment valuation equation, it does not appear that traditional energy company valuation metrics will be completely tossed aside. Therefore, most of the prescribed solutions for helping energy companies recover from the devastation wrought by the late 2014 oil price collapse are similar to those employed in earlier downturns.

To gain a greater appreciation for whether the energy industry’s history is currently being repeated, a brief review of the industry’s history of the past 60 years may prove useful. In 1960, the domestic oil business was slightly over 100 years old. While a handful of large oil companies dominated the business, the top oil and gas producers were the product of managements accumulating the assets of smaller companies in the past. Many of the large producers had also expanded operations into hydrocarbon transportation, refining and petrochemical operations.

A July 2016 McKinsey study entitled “Mergers in the oil patch: Lessons from past downturns,” offered the following observation:

“Past collapses in oil prices have prompted a deluge of deals. As activity looks set to pick up again, companies that acquire in order to cut costs are likely to be the most successful.”

The message of consolidation and cost-cutting for success is as popular today as in the past, as demonstrated in the McKinsey report. The report contained a chart of the history of the oil industry from 1900 through 2015 showing significant merger and acquisition (M&A) points along a timeline of real oil prices, while the oil price in dollars-of-the-day is also displayed. The primary conclusion of the study was that most oil industry M&A activity has occurred in flat or falling oil price environments. The exception was the M&A activity during 1998-2015, which occurred as oil prices were rising. This M&A activity was likely driven by different considerations. With the late 2014 oil price collapse and no quick rebound, the authors of the study believe another wave of M&A activity is poised to begin, but it needs to be driven by the same considerations that drove M&A in all prior cycles with the exception of the most recent period.

Exhibit 1. Oil & Gas M&A Occurs When Oil Prices Are Low

Source: McKinsey

While low oil prices are equated with distressed fortunes for oil companies, the value extracted from M&A activity comes primarily from realizing cost synergies when companies combine. The McKinsey study examined the difference in the results of M&A driven by low oil prices compared to deals that occurred in a rising oil price environment. As a result, the focus was on the performance of deals completed in the low oil price period of 1986-1998 versus deal performance during the rising oil prices of 1998-2015. The study was looking to better understand the catalysts behind the deals done during these respective oil price environments. A conclusion of the study was that the thinking behind the M&A deals done during rising oil prices would not work in a low oil price environment. Thus, producers looking to do deals now should be focusing on the M&A drivers of the low oil price period.

For our purposes, we are less concerned with the rising oil price era, but rather, we are interested in understanding what drove those deals in the low oil price periods and if those conditions exist today. Therefore, besides looking at the oil and gas M&A activity during 1986-1998, we are examining M&A activity during the 1950s and 1960s, which the chart in Exhibit 1 calls the “2nd wave of industry restructuring.”

The 1950s and 1960s were characterized by slowly declining oil prices, while consumption was steadily rising after the Second World War. In that era producers struggled to grow output. In addition, their long-term outlooks for the oil market suggested the U.S. was heading for a peak sometime in the 1970s, meaning their future growth was in doubt. With output struggling and oil use expanding, oil imports were soaring. That caused the Eisenhower administration to institute a mandatory oil import quota program to prevent lower foreign oil prices crippling the domestic oil industry. The quota system, instituted in 1959, was set at 12.5% of domestic production. It was repealed by the Nixon administration in 1973 in response to the oil crisis.

While many of the 1950s-1960s oil M&A deals were done to help producers increase their domestic scale, some were done to help accelerate the entry of domestic producers into international markets. But industry deals providing greater insight into the thinking of producers were those taking companies outside of the oil and gas business. For many, the journey wasn’t too far. In fact, for most it was only into neighboring fuel markets – coal and uranium. These fuels were in keeping with the energy supply and demand modeling the companies had been doing and which was guiding their long-term corporate strategies.

In hearings before Congress in the fall of 1975 dealing with the structure of the energy industry, two oil company executives presented their companies’ rationalizations for why they had diversified into coal. William T. Slick, Senior Vice President of Exxon Co., U.S.A., pointed out that in the early 1960s, his company had projected that domestic oil and gas production would peak in the early 1970s, and would bring an increasing reliance on foreign imports bringing with it national security problems. Thus, Exxon concluded there would be a substantial future need for synthetic oil and gas made from domestic raw materials, primarily coal.

Mr. Slick went on to cite Exxon’s expertise in processing hydrocarbons in its refineries. As he told the congressmen: “The basic chemical reactions and the basic chemical process design concepts that apply to petroleum feed stocks have a direct bearing on the conversion of coal, which in itself is a hydrocarbon, into gaseous and liquid forms.” The company believed that much of its R&D work associated with refinery operations would prove useful in developing processes for converting coal into gas or liquids.

Other reasons why this investment made sense, he stated, was because coal is a fuel with direct marketability, regardless of the success or failure of Exxon’s research into converting coal to other fuels. Lastly, the investment profile for coal mines was similar to that of oil and gas projects, so Exxon felt comfortable operating in the coal industry with its long-term investment profile.

Exxon wasn’t the only oil company that diversified into coal – Continental Oil Company (Conoco) – was another, having purchased Consolidation Coal Company in 1966. William Hardesty of Conoco presented a similar rationale for his employer’s move into coal. Exxon took a different route for entering the coal business by purchasing undeveloped leases and commencing mining operations on its own. Both Conoco and Exxon also ventured into mining and processing of uranium ore for the emerging nuclear power industry, which as of the early 1970s was projected to have a bright future.

In 1976, during a private lunch with Kenneth Jamieson, the recently retired president of Exxon Co., U.S.A. and a director of parent Exxon Corp., he told us the future for Exxon was in “hard rock minerals.” That meant coal, uranium and copper. Mr. Jamieson was a Canadian mining engineer who had been recruited to join Exxon, through whose management ranks he rose, eventually reaching the top position and helped guide the company’s investment in mining.

The mid-1970s was also a time when Exxon was announcing its entry into the office products business to compete with the likes of Xerox and IBM by manufacturing and selling copiers, word processors and electric typewriters. The company targeted generating $1 billion in sales from this division by 1985. The venture ended in 1984 after failing to generate the revenues anticipated, and actually producing losses of about $70 million a year, or approximately a third of the division’s revenues.

The office products debacle was added to the company’s failure to succeed with its synthetic gas venture and a failed attempt to devise a new electronic control system for electric motors, which had prompted Exxon to purchase Reliance Electric Company, a leading electric motor manufacturer. The Reliance acquisition occurred in 1979 amid cries from company critics that this was a disguised diversification effort. Exxon officials said that was not the case, and suggested that the ultimate cost of the failed control system proved to be less than it often invested in new oil and gas R&D efforts. Since Exxon recouped much of the Reliance purchase price through its eventual sale, the lost investment was not consequential.

A 1981 New York Times article discussing the Reliance venture pointed out that Exxon’s move “pales besides such recent oil company acquisition moves as Standard Oil of California’s $4 billion bid for Amax [a minerals company], Joseph E. Seagram & Sons’ $2 billion bid for St. Joe Minerals Corporation, and Standard Oil of Ohio’s $1.77 billion bid for Kennecott Corporation [copper mining]. Seagram had earlier engineered a takeover attempt of Conoco and owned a 32% interest. Conoco brought in DuPont Chemical as a white knight to buy Conoco when Seagram attempted to purchase the rest of the company. The resulting DuPont deal left Seagram with a 24.3% ownership in DuPont, which it later monetized to enter the entertainment business.

In terms of straying from the oil and gas business, probably the most noteworthy departure was the revelation of Gulf Oil Corporation’s planned acquisition of Ringling Bros. Barnum & Bailey Combined Shows, Inc. from Mattel, Inc. in 1974 at the height of the energy crisis. The Gulf Oil Board of Directors voted the deal down after being severely criticized by investors, the media and politicians.

Another noteworthy diversification effort by a major oil company during the 1970s was Mobil Oil’s purchase of Montgomery Ward in 1976 for $1 billion. The retailer owned the Container Corporation of America, a leading paper products company, adding another commodity business line. In early 1977, Atlantic Richfield Company (ARCO) bought Anaconda Copper Mining Company for $708 million after the miner had rejected a purchase offer from a consortium led by Tenneco offering $500 million. Anaconda was eventually shut down due to its high-cost mining operations.

These deals highlight how companies’ business strategies drove how they invested shareholder money. The deals of the 1960s and 1970s were driven by the belief that future oil and gas growth was limited, so diversification either into other hydrocarbon fuels, alternative businesses, or to increase scale and expand into international oil and gas markets was needed to sustain their businesses. Those strategies began to change in response to the dramatic increase in crude oil prices in the 1970s and opening of global oil and gas opportunities. However, the energy industry changed in the mid-1980s as oil prices crashed and stayed low through the 1990s.

There were several other factors at work in the producing sector that drove industry restructuring. One was the lackluster reserve replacement ratios and high finding and development costs during the first half of the 1970s. Another consideration was that between 1981 and 1985, due to the existence of the U.S. windfall profits tax, much of the rise in oil price above $20 per barrel was taxed away. Therefore, the true financial pain for the producers only began to kick in once oil prices fell below $20, which was after 1985.

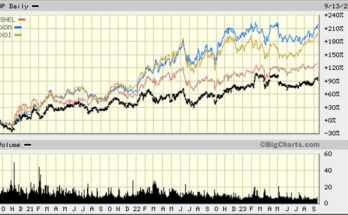

Exhibit 2. Oil Industry Didn’t Do Well During Oil Boom

Source: Federal Trade Commission

With the domestic market appearing to offer little attraction, many producers began to focus on participating in international markets where the opportunities to discover large reserve pools at low costs existed. At the same time, the disappointing returns from earlier diversification moves led companies to jettison businesses enabling producers to focus on their core oil and gas operations and to provide funds to expand those operations. There was also a push for the producers to reduce their debt levels.

The first wave of major oil and gas company acquisitions began in 1984 when Chevron purchased Gulf Oil, Texaco bought Getty Oil, and Mobil Oil purchased Superior Oil. The industry consolidation continued, but at a slow pace due to the pressures of managing businesses in a low oil price environment. Many of the deals in the late 1980s and early 1990s were driven by financial pressures. The last major burst of industry M&A activity occurred in 1997-1999, which happened to coincide with another oil price shock. At that time, OPEC misjudged the anticipated Asian demand growth due to a real estate boom, which dissipated in the region’s currency crisis. The oil price drop created opportunities for industry consolidation. During this period, BP acquired AMOCO and then ARCO, and was followed by the blockbuster of Exxon merging with Mobil Oil.

Other major oil industry deals at that time involved French producer Total merging with Belgian company Petrofina, and Spanish oil company Repsol buying Argentinian producer Yacimientos Petroleos Fiscales (YPF). Domestically, Kerr-McGee and Oryx Energy combined, as well as Seagull Energy and Ocean Energy. Combining to gain greater scale and to fill gaps in company portfolios appeared to be the driving forces behind these deals.

A parallel restructuring of the oilfield service industry also occurred between the mid-1980s and end of the 1990s. The wave of consolidation was driven initially by perceived growth opportunities. However, the sudden destruction of the industry’s financial condition due to collapsing oil prices and the need to resize businesses for slower growth and potentially a smaller industry drove later combinations.

Prior to the 1960s, the oilfield service industry in the United States had a strong regional flavor to it that arose from the growth of local oil and gas markets. Today, you can hardly identify companies whose creation and growth were tied to local oil and gas basins such as Oklahoma, Louisiana, Texas and Southern California.

Many people do not appreciate that it was only seven years after Col. Drake drilled his first well near Titusville, Pennsylvania in 1858 that the Union Mattole Company began producing oil near Petrolia, California. By 1903, California was the leading oil producing state in the United States with about 200 active oil companies. Between 1903 and 1930, California and Oklahoma traded positions as the number one oil producing state, only to be overtaken by Texas during the Great Depression.

An entire oilfield service industry grew and prospered, as the companies created needed products, services and technology utilized throughout the domestic and international oil business. At one point in the mid-1970s, after investors and Wall Street fell in love with energy and oilfield service stocks, the California service companies created their own investment conference called “The Snowbird Conference.” The name was derived from the decision to hold the conference, usually in Newport Beach, California, in January. The sun and balmy temperatures guaranteed a strong contingent of analysts from the cold and snowy Northeast and Midwest, and even those of us from Texas. The attraction for analysts was the large number of oilfield service companies that could be visited, including: Baker Oil Tools, the Byron Jackson oilfield-equipment division of Borg-Warner, Fluor, Global Marine, H&H Rentals, Hydril Corporation, Petrolane, Regan Offshore, Santa Fe International, Smith International, Trico, Varco, and Vetco Offshore (we may have missed some).

The conference grew from the logistical nightmare that evolved after analysts coordinate visits with individual managements at their company offices. Prior to the conference, the analysts would caravan across Southern California to attend meetings, always hoping never to get lost or caught in traffic jams that upended the meeting schedule.

In those days, the service companies were smaller and more narrowly focused, in contrast to the wide product and service offerings of the major service companies today. Many of the companies became parts of others over time, except for Baker Oil Tools. How companies grew was often a function of their ownership, and certainly due to their economics. Many companies were family-owned or controlled. That often limited their ability to grow. Consolidation was important as a way to create the scale necessary to become publicly-owned and tap the capital markets necessary to fund growth, geographic expansion and entry into markets that would help dampen the volatility of the drilling cycle.

To appreciate how oilfield service companies grew, we will trace the history of two of the most prominent oilfield service companies founded nearly at the same time – one from California and the other from Texas. The two companies are Baker Oil Tools and Hughes Tool Company, which today form Baker Hughes Company, the recently spun-off company from General Electric.

In 1903 in Southern California, Reuben C. “Carl” Baker patented an innovative cable-tool drill bit after founding Coalinga Oil Company. Over the next few years, as he encountered challenges in drilling wells, he designed other tools to help improve his success. In 1907, he developed and patented the Baker Casing Shoe, a device that revolutionized cable-tool drilling by ensuring the uninterrupted flow of oil through the bottom of the casing in a well. The Baker Casing Shoe Company was formed in 1913 to hold and license Mr. Baker’s patents. The company expanded by adding other completion, cementing and fishing tools and began manufacturing its products. In 1928, the company’s name is changed to Baker Oil Tools, and in 1961 it became publicly owned.

When the third CEO of Baker Oil Tools assumed control in 1965, E.H. “Hubie” Clark emphasized greater professionalism in managing and planning the company’s future. Under his leadership, the company made 20 acquisitions adding multiple new product lines to its business. In 1975, the company purchased the Reed Roller Bit Company, moving into a highly concentrated and profitable market segment. This was a significant deal that helped propel the company’s growth and added further diversification into drilling products and services. It also precipitated a name change to Baker International to better reflect the company’s global business scope.

Baker International was considered to be the best managed company in the oilfield sector. It devoted extensive efforts to planning and strategizing based on extensive surveys and market intelligence gathering. Earlier in this series we highlighted a market assessment delivered by Mr. Clark projecting a bright future for the industry in the 1980s as oil and gas companies around the world would set out to find, develop and produce the energy the global economy would need. The best laid plans for the future were shattered by what the extended period of extremely high oil prices did to energy demand and supply. The industry downturn during the first half of the 1980s forced significant industry retrenchment. All the downsizing and restructurings, despite the managerial talent, couldn’t keep the company from suffering financially. It set the stage for a dramatic restructuring move involving combining with its chief competitor, Hughes Tool Company.

In 1909, the first two-cone roller cutter bit was introduced after being secretly tested in a well at Goose Creek, Texas. Its success led to the formation of the Sharp-Hughes Tool Company, jointly owned by Walter Sharp and Howard Hughes. In 1912, Mr. Sharp died and his widow sold his ownership to Mr. Hughes. In 1915, the company’s name was changed to Hughes Tool Company. In 1924, Mr. Hughes died and three-quarters of the company ownership passed to his son, Howard Hughes, Jr., a student at Rice University. He convinced his other relatives to sell him their ownership interests so he attains complete control of the company.

Beginning at age 18, Mr. Hughes, Jr., was paid $50,000 a year and was able to charge all major expenses such as airplanes, automobiles and houses to the company. In 1934, the company’s engineers designed and patented a three-cone roller bit, which is the basic design of bits to this day. With exclusive patent protection lasting until 1951, Hughes Tool revolutionized oil well drilling, expanded worldwide, and its lucrative cash flow funds the many aviation, real estate and entertainment ventures of the young Mr. Hughes. He eventually became one of the richest men in the world, and most eccentric, too. At times, Hughes Tool Company owned controlling interest in TWA airlines, a minority interest in Northeast Airlines, the RKO company, which was involved in movies, theatres, and radio stations, Sports Network Inc., renamed Hughes Television Network, a beer brewery located on the company’s property in Houston, and numerous hotels and casinos in Las Vegas, where Mr. Hughes lived. In the 1930s, he founded Hughes Aircraft Company as a division of Hughes Tool Company, and it thrived on contracts to build airplanes during World War II, ultimately becoming one of the largest defense contractors and aerospace companies during the 1950s. That business was donated to the Howard Hughes Medical Institute as its endowment. In 1972, Hughes Tool Company was sold in a public offering under the direction of Merrill Lynch, ending Mr. Hughes’s involvement.

Under the leadership of Raymond Holliday, an accountant who had managed the affairs of Mr. Hughes, Hughes Tool saw its market capitalization grow from $150 million to $450 million. Mr. Holliday recognized that the company needed to build additional manufacturing plants around the world to meet the growing demand for drill bits, but he also saw that larger service companies were beginning to move into the highly profitable bit market. Given the more competitive marketplace and to bolster the company’s market valuation, Mr. Holliday began a diversification effort that began in 1974 with the purchase of the Byron Jackson division of Borg-Warner, followed by the Regan Offshore Company, and in 1978, Brown Oil Tools with its 377 underutilized patents.

By 1981, the peak year for oilfield activity, 55% of Hughes Tool revenues came from non-drill bit products. That diversification didn’t save the company during the industry’s downturn in the early 1980s because virtually 100% of revenues were derived from the oil and gas business. Debt, a bloated corporate structure, and too many manufacturing plants forced a significant restructuring, which was planned by consultant Bain & Co. But, as industry activity fell further in 1985, the company was in trouble. However, that didn’t stop it from continuing to try to expand its business scope in hopes of better times down the road.

In the summer of 1986, Hughes Tool agreed to purchase the Vetco Gray drilling equipment division of Combustion Engineering (CE) for $270 million in cash and stock. The unit became the core of a joint venture, Vetco Hughes, owned 80% by Hughes Tool and 20% by CE. Hughes Tool also contributed its Regan Offshore division to the joint venture. This transaction is a piece of an interesting history, which is relevant based on our earlier discussion of the diversification strategies of the major oil companies in the 1960s and 1970s of investing in the coal business.

CE, founded in 1912, was primarily a builder of industrial and utility boilers for power plants. It played an important role in the development of the U.S. nuclear power business in the 1950s. In the late 1960s, CE began a diversification effort built on the company’s energy engineering skills that it believed would be applicable in adjacent mineral and utility markets. One of its eventual business units was the Oil & Gas Group. That group acquired a number of oilfield equipment suppliers: Natco, Gray Tool, Vetco, Beaumont Well Works, and Houston Forging. Gray Tool was purchased in 1976 when CE played the white knight to foil a takeover attempt by Joy Manufacturing, a mining equipment company that was attempting to diversify into oil and gas equipment to capitalize on the 1970s oil boom.

As Hughes Tool was completing the Vetco Gray deal, its business was falling rapidly, at which point it was approached by Baker International about a combination. The merger was announced in October 1986 and involved an all-stock transaction valued at roughly $460 million. To appreciate how dramatically Hughes Tools’ business was deteriorating, during the week of July 14th, the drilling rig count fell to a record low of 663 active rigs, about one-third of its level in the prior year. For 1985, Hughes Tool earned $4 million on revenues of $1.2 billion, and analysts were estimating the company would generate $800 million of revenues in 1986, but lose money. In fact, for the third quarter ended September 30, 1986, Hughes Tool lost $41.1 million on revenue of $158.8 million, compared with revenues of $312.5 million and earnings of $1.9 million in the same quarter of 1985. With depressed rig counts and oil prices, the outlook for business was not good.

Things were not much better at Baker International, which had reduced its 20,000-employee work force by 5,500 over the first 10 months of 1986. It had also taken a $410 million write-down of the value of its assets. The best way for companies to address excessive overhead, excess manufacturing capacity, surplus equipment, and too many employees was to combine operations. The key hurdle the deal had to overcome was opposition from the U.S. Department of Justice’s antitrust division. It wanted Baker International to sell its Reed Tool division, which held a 19% share of the worldwide drill bit market. Coupled with Hughes Tool’s 36% market share, the combined company would hold over half the market, leading to potential monopolistic power. The government gave Baker International three months to complete the sale.

Hughes Tool objected that the time limit was too short and would lead to a fire sale transaction. It felt that with more time, a better deal could be realized. A longer time frame, Hughes Tool management believed, would help Baker International to find a buyer for Reed Tool’s domestic drill bit business and its Singapore manufacturing plant, leaving the remaining international facilities with the new company, helping its business. Due to its concern about the arbitrary deadline, Hughes Tool’s management threatened to call off the merger. A story in The New York Times, announcing that Baker International had a buyer for Reed Tool in Camco Inc., stated: “After Hughes threatened to withdraw from the merger – and just as suddenly recanted and decided to continue negotiations – the Justice Department agreed last week to extend the deadline.”

There is a little-known story behind the recanting episode. It was a rainy spring morning when Hughes Tool chairman and CEO James Lesch telephoned James Woods, chairman and CEO of Baker International, to tell him of his company’s plans to abandon the merger over the Justice Department’s ruling. While angry at the decision, Mr. Woods had prepared a contingency plan. He told Mr. Lesch he wanted a meeting with him that afternoon. When Mr. Woods arrived at the Hughes Tool offices in Texas Commerce Tower in downtown Houston, in tow was famed attorney Joe Jamail, Jr., the King of Torts. Barely a year earlier, Mr. Jamail had won a $10.5 billion jury award representing hometown oil company Pennzoil in its case against Texaco over a reneged merger agreement. The prospect of being sued by Mr. Jamail was too much for the Hughes Tool management, who quickly recanted their decision and moved forward with the merger.

The shadow of Hughes Tool was always cast over the competitive drill bit market. Years earlier, Hughes Tool engineers designed and patented an O-ring seal for the bearings facilitating the rotation of the roller cones of the drill bit from overpressure, causing them to seize up. This feature was openly infringed upon by every drill bit manufacture with the exception of Reed Tool. In the early 1970s, infringement suits were brought by Hughes Tool against its major competitors, but like most patent cases it took years to work through the legal system. In 1985, Hughes Tool was awarded $122 million in damages from the Security drill bit division of Dresser Industries for its infringement, which was a welcome infusion of cash as the business was spinning downward. In 1986, Hughes Tool won a $227 million judgement against Smith International. This verdict, coupled with the devastating business environment, forced Smith International into bankruptcy. While the award nearly upended the post-bankruptcy business plan being developed by Smith International management, the bankruptcy actually gave Smith International leverage in settlement negotiations. In the spring of 1987, Smith International agreed to pay $85 million in cash and $10 million of notes to settle the case.

The downsizing, restructuring and divestiture moves Smith International undertook as it dealt with the eroding oilfield market beginning in 1982 were similar to those of Hughes Tool, Baker International and the rest of the oilfield service industry. Bankruptcy became an effective tool for preserving the core of many businesses, often allowing them to reorganize as smaller entities and with improved balance sheets for weathering the environment.

To provide a perspective on how much the oilfield service sector has changed since those days, we have recreated a table published by energy investment bank Simmons & Company International of publicly-traded contract drilling companies in 1981. Old timers will probably recognize some of the names, but there are 38 drillers listed. In a January 14, 2020, Oilfield Services & Equipment industry update published by analyst David Anderson of Barclays, there was a total of 30 oilfield service companies listed. There are only three land and four offshore contract drillers. There are a few additional publicly-traded drilling contractors, but their market capitalizations and financial conditions do not justify researching them. The point is, there is only a fraction of the number of drilling contractors operating today compared to the peak of the industry boom.

Exhibit 3. Drilling Contractor Stocks During Oil Boom

Source: Land Rig Newsletter, PPHB

Another interesting take on drilling industry consolidation is to realize that Nabors Industries, one the largest drillers today, traces its roots to the first company on the Simmons list – Anglo Energy. We won’t recap the detailed history of how Eugene Isenberg, with the help of distressed debt investor Marty Whitman, gained control of Anglo as it exited bankruptcy in 1986 and used it to build Nabors Industries, but suffice it to say that it was a glorious string of corporate acquisitions, including some of those on the 1981 list. Nabors has completed 49 corporate and asset purchases between 1987 and 2010, along with huge capital reinvestment in the business. The depressed oilfield service industry during the 1990s was a catalyst for this consolidation.

Exhibit 4. Oilfield Service Company Bankruptcies Climb

Source: Haynes and Boone

The industry’s poor health today is exemplified by the increase in bankruptcy filings by both producers and oilfield service companies. Lawyers at Haynes and Boone track these filings and report the number and magnitude of debt involved. Their latest tally for the service sector is in Exhibit 4. While it would appear that the pace of new bankruptcy filings slowed in 2019, it is important to acknowledge that in a number of cases, oilfield service companies in severe financial distress are often working for months with their bond and debt holders to develop a pre-packaged plan for restructuring the balance sheet and corporate ownership, as well as developing a business plan for the post-bankruptcy company, prior to filing for Chapter 11 protection. This reduces the disruption caused by bankruptcy by shortening the time from entry to exit. Our sense is that there will be other oilfield service companies entering bankruptcy before the industry recovery begins to accelerate. In fact, understanding the shape and timing of the recovery plays a critical role in shaping the final plans for exiting bankruptcy.

Just as the producer sector needed nearly 15 years to complete its transformation following the collapse of global oil prices in the mid-1980s, so too did the oilfield service sector. The two final oilfield service industry transformative deals occurred in the first half of 1998. Halliburton agreed to acquire Dresser Industries in a $7.7 billion merger in February, and Baker Hughes merged with Western Atlas in a $5.5 billion transaction in May 1998. Following these deals, the global oilfield service industry was left with three very large service companies with broad portfolios of products and services along with the global scale to deliver them to customers worldwide. Scale-to-scale was the mantra driving the energy business restructuring as the end of the 20th century approached. The current restructuring of the global oil and gas industry suggests that optionality is becoming more important than sheer scale. For the oilfield service industry, serious self-examination of company core strengths is being undertaken, which is leading to meaningful restructuring of companies from top to bottom within the sector. Understanding what the defining mantra is for the energy industry for the next decade will shape its future and how producers and service companies will have to look and operate to be successful.

Automobile Revolution’s Impact On Energy Markets (Top)

Where one stands on the pace of increase in electric vehicle (EV) sales dictates where you are on the future of the oil business. The most bullish proponents for EVs signal they are about to turn off the lights on the Oil Age. Au contraire, comes from those believing EV sales will grow much more slowly than the optimists foresee, thus extending the oil business’ future. They do admit, however, that the industry’s growth will cease at some point within the foreseeable future, but the predicted demise of the industry is too extreme. If one scenario is black while the other is white, then there is a very wide array of grays in the middle.

Those with a singular focus on EVs, and their potential impact on oil consumption may fail to appreciate the subtle changes underway in the economy that could influence the future of the transportation and energy sectors. To assess how mobility changes within the transportation space might impact the automobile and energy sectors, IHS Markit, under Dan Yergin’s direction, introduced a new research service in 2017 that utilizes scenario planning, to help predict possible outcomes. They characterized the challenges in one of their marketing pieces, writing the following:

“For the first time in more than 100 years the automotive ecosystem faces a convergence of technological, political, and economic forces that could fundamentally alter how cars are sold, used, and powered. Driverless technology, electric vehicles, new mobility services, and public policy are prime disruptive forces. These forces will enhance the value of car transport, including lowering costs in many cases. This change is underway; the only question is how quickly it will occur and how transformative it will prove. Not only will the automotive industry see significant change, so will the energy industry and the chemical industry as they are inextricably linked.”

That statement provides a broad assessment of the range of corporate challenges and the breadth of industries that the new service is designed to help. As with any broad study, it often obscures or misses the impacts from less prominent issues. Studying these issues, as well as their possible trajectories and impacts, is important. According to the International Monetary Fund (IMF), the automobile sector accounts for 5.7% of global economic activity and 8% of world trade.

Exhibit 5. Do Slumping Auto Sales Look Like A Trend?

Source: CNBC

The IMF suggested that the auto sector contributed about 20% of 2018’s slowing of global gross domestic product. They also think it accounted for a third of that year’s slowdown in global trade. The importance of automobiles to the global economy is because it is a major consumer of steel, aluminum, copper, rubber, plastics and electronics, which impacts the production of the raw materials, their transportation to manufacturing sites, and the energy to produce them. The health of the global automobile industry will impact the health of the global economy.

One discovers when examining the United States automobile market that you have to pay attention to the difference between retail car sales and total vehicle sales. That difference references fleet sales rather than those done via the dealer showroom. That issue doesn’t address the challenges auto manufacturers are experiencing with the shift in consumer preference for sport utility (SUV) and crossover vehicles rather than sedans. Consumers are also buying more pickup trucks. Trucks, SUVs and crossover vehicles carry better profit margins, which helps auto manufacturers’ profitability, as they deal with slower overall sales, loss-making EVs, and profitless small cars with high fuel efficiency ratings that help a manufacturer meet the overall fleet fuel-efficiency mandates.

Exhibit 6. 2019 U.S. Auto Sales Estimates

Source: J.D. Power

An article by J.D. Power and LMC Automotive showed the retail versus total vehicle sales estimate for December 2020 compared to November and December of 2018. The table also shows the two sales totals at seasonally-adjusted-annualized-rates. Based on the December 2019 estimates, both annual sales forecasts called for a roughly 500,000-unit decline from the prior year. However, if one looks at the 11-month figures, retail sales decline by 900,000 units, as total sales only fall by 300,000 units.

The distinction between the two sales estimates figured prominently in a recent article on TheDrive.com discussing the results of a J.D. Power and LMC Automotive study about 2020’s automobile sales. The article stated:

“Specifically, the report suggests that U.S. consumer auto sales will reach around 13.48 million units by the end of the year– that’s a decline of 205,000 vehicles from 2019 and an estimated 18.3% downturn since the industry’s last year of growth in 2014.”

When viewed from the perspective of total vehicle sales, we find a different pattern. Although the J.D Power and LMC Automotive study also projects a decline in total sales of 300,000 units (16.8 million versus 17.1 million units), the peak sales year was 2016 when 17.6 million vehicles were sold. That is a two-year difference between the peak in total car sales and retail car sales. While a decline in total sales is bad for the auto manufacturing companies, the impact of a longer retail sales decline is greater on dealers than the manufacturer. Of course, the two are inextricably linked since manufacturers often have to provide financial incentives to help dealers sell the cars produced, reducing the manufacturer’s profit.

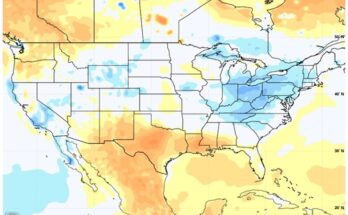

From the perspective of the health of the global automobile industry, many markets have peaked. The U.S. peaked in 2016, well after the European Union (EU) peak in 2000 and the Japanese one in 1990. Increasingly, the automobile world, as well as the energy business, is coming to depend on developing economies for their growth. However, automobile markets in some of these countries are struggling. For example, China is facing its third year of falling automobile sales, and that projection was made prior to the emergence of the coronavirus, which some economists suggest could cut the country’s economic growth by a third in 2020. If that happens, the Chinese automobile industry, as well as vehicle exporters to China, will be victimized even more.

Exhibit 7. Prospects For China Auto Sales In 2020

Source: China Association of Automobile Manufacturers

The Indian automobile market is also important, but a much different automobile market from most we study. As Exhibit 8 shows (next page), the country sold over 25 million vehicles in FY2019 (FYE is March 31), but over 20 million were motorcycles. The vehicle market has been suffering through one of its worst periods with sales falling by 19% during calendar 2019. The decline, and current slow recovery, has pushed off the target for India to become the third largest automobile market in 2020. Estimates are that this goal may not be reached until 2024.

To become the third largest auto market, the Indian economy will need to adjust to the tighter pollution control standards being implemented this summer, as well as the increase in vehicle costs

Exhibit 8. India Vehicle Sales By Type

Source: Statista

accompanying the new standards. In addition, consumers will have to deal with the planned increases in vehicle registration fees.

Bharat stage emission standards (BSES) are the emission standards instituted by the Government of India to regulate the output of air pollutants from internal combustion engines and Spark-ignition engines. These standards, and the timeline for their implementation, are set by the Central Pollution Control Board under the Ministry of Environment, Forest and Climate Change. Effective April 1, 2020, the pollution standard will increase to BS-VI, skipping BS-V. The Indian Supreme Court has ruled that effective with the new pollution standard, no vehicle with BS-IV controls can be sold or registered in the country. The tightened pollution standards are due to the increased dirty air in the Delhi region, but the new rules are being extended nationwide to hurry along the government’s plan for cleaning up India’s atmosphere. The accelerated pollution plan is creating challenges for automobile and other vehicle manufacturers.

It is estimated that meeting the BS-VI standards will boost the cost of gasoline-powered vehicles by about Indian Rupees (Rs) 15,000-25,000 ($209.70-$349.51) and by Rs 50,000-70,000 ($698.99-$978.62) for diesel vehicles. Not only will these cost increases dent demand because they boost vehicle costs by an estimated 3%-5%, but auto manufacturers are scaling back output by up to 20% for December 2019 through February 2020 in order to manage inventory.

Additionally, a recent draft notification from the Ministry of Road Transport and Highways proposes a meaningful jump in the registration costs for vehicles. While the increase is on hold, it will come into force in June 2020. The registration cost for new cars will be increased to Rs 5,000 ($69.90) from the current cost of Rs 600 ($8.39). All other vehicle registration fees will also increase, with the cost for two-wheelers rising to Rs 1,000 ($13.98) from the existing cost of Rs 50 ($0.70).

A Wall Street Journal article last October focused on the peaking in automobile sales in the most developed economies and regions of the world, and how that trend may be emerging in developing economies and regions. The article included a chart showing the various peaks, besides the current fall-offs in sales in China and India. While 2020 will be difficult for these two countries, no one has written them off over future growth. However, there may be forces at work in each country that could impact the future rates of growth of automobile sales compared to their historical rates.

Exhibit 9. Where Auto Market Sales Have Peaked

Source: WSJ

Issues that could impact future growth rates for automobile sales in China and India include the former’s aging population, and the rapid population growth of India. Both countries are dealing with increased urbanization producing greater air pollution and pressure for greater restrictions on the use of personal automobiles and the way vehicles will be powered in the future. Policy decisions dealing with these population and economic trends will create dislocations in the evolution of the countries’ transportation sectors and automobile industries, as well as weigh down the pace of future growth.

To appreciate the make-up of the global automobile industry, and why regulations and policy decisions in certain countries can impact the entire industry, it is important to see the ranking of national vehicle markets. Using the latest global data (2018) from the International Organization of Motor Vehicle Manufacturers (OICA), we have ranked the top 12 national automobile markets. As the table shows, those markets accounted for 74.9 million vehicles sold in 2018, or nearly 79% of the world’s output of 95.1 million units.

Exhibit 10. Top Countries For 2018 New Vehicle Sales

Source: OICA, PPHB

China is by far the world’s largest automobile market, which explains why its push for electric vehicles (EV) to address its urban pollution problems has forced every car manufacturer to commit to building them if they want to continue selling cars in China, even though EVs are not presently profitable. Combined, China and the United States represent nearly half the world’s automobile sales. With both of those markets looking at down years for auto sales in 2020, the questions become when will they recover and what happens to the automobile industry in the interim?

In the Wall Street Journal article, Michael Dunne, chief executive of ZoZo Go, a consultant specializing in the Asian automobile market, pointed out that China, with 1.4 billion people, should be far from saturation. However, most Chinese who can afford a car are clustered along the eastern coast in major cities, “and those city markets have largely become saturated,” he said. In response to dirty air and congestion, urban governments are restricting new car registrations, while EVs are losing their subsidies, as the government is trying to stimulate its economy by incentivizing the purchase of conventionally-powered cars. According to Mr. Dunne, due to the cost and hassle of owning a car, many affluent urban Chinese own just one vehicle and use a ride-sharing service in place of a second.

In the United States, air pollution concerns in metropolitan areas, along with growing congestion, are prompting local officials to enact laws and rules restricting car use and boosting mass transit. Tax subsidies for clean automobiles remain in flux, with a record of impairing EV sales whenever subsidies are reduced. EVs are becoming more price-competitive with internal combustion engine (ICE) cars, but without the tax subsidies, they still remain largely out of the reach of most car buyers. Besides their cost, EVs struggle with an inadequate network of public charging stations, which is the easiest way to combat consumer range-anxiety fears, which also holds back EV sales.

The European Union, consisting of 28 member countries, along with the European Free Trade Association (EFTA), sold slightly over 18 million cars in 2018. The EU, with China and the U.S., sold a combined 63.8 million cars, or 67% of the world’s vehicles. That makes the EU + EFTA an important global automobile market. The EU is leading the global charge on climate change and cleaning up the atmosphere. As a result, governments are enacting regulations restricting the use of ICE vehicles and even outright banning them in favor of EVs, which they are promoting with various subsidies. Presumably the EVs will be powered by the clean-energy industry European countries are developing.

After lagging behind other European countries, Germany has become much more aggressive in implementing environmental restrictions impacting its automobile industry. Effective January 1, 2020, new carbon emission rules came into effect for the European Union. For Germany it means actively promoting EVs, which have a negative impact on the country’s automobile manufacturing business and its vendors. This transition will span a longer period than just 2020, as the German auto industry adjusts to the new regulations and the need to compete more aggressively against EV manufacturers who have been producing vehicles for longer.

According to the new environmental rules, the average new car registered in the EU must not emit more than 95 grams of CO2 per kilometer, which corresponds to fuel consumption of roughly 4.1 liters of gasoline or 3.6 liters of diesel per 100 kilometers. That is the equivalent of 1.1 gallons of gasoline per 62.2 miles, or a 60-miles-per-gallon fuel efficiency. This new standard will force (already has) automobile manufacturers to reassess their business strategies. Unfortunately, the new regulations are coming at a time when the global auto market is under pressure. Germany’s car emissions performance ranked second to last among the 23 European countries on a volume-weighted basis. In 2018, Germany’s fleet emitted 129.1 grams of CO2 per kilometer (gm/km), an increase of 1.9 from 2017. Only Switzerland had a worst emissions performance.

Exhibit 11. European Country Auto CO2 Rankings

Source: thedrive.com

Car manufacturers can continue to sell more polluting vehicles, but they must compensate by selling enough low- or zero-emission vehicles to get overall fleet emissions down to the standard if they want to avoid hefty fines that could add up to billions of euros for major car groups. Those fines would come at the same time these car groups are still paying for the diesel emissions cheating scandal and the high costs of transitioning their plants to building EVs.

Based on the plans and status of European vehicle manufacturers for meeting the EU’s 2021 CO2 emission standard, the three major German car manufacturers will be struggling to avoid huge fines. Of the 13 vehicle suppliers to the EU, only five are projected to meet or surpass the emissions standard and thus avoid fines.

To meet the new EU standard will require substantially more EVs. Based on data from research firm KBA, new EV registrations in Germany in 2019 increased by 75.5% to 63,281 battery electric cars. This brought its share of the German new car market in 2019 to 1.75% from 1.05% in 2018. This market share gain came as the total German new car market grew by 5% in 2019 to 3,607,258 cars, of which 59% were gasoline-powered and 32% were diesel. The

Exhibit 12. 2021 European Auto CO2 Compliance

Source: CAR Magazine

fleet growth was helped by a strong fourth quarter for sales of SUVs and other larger ICE cars intended to beat the imposition of the new CO2 regulations. Those sales contributed to the entire 2019 vehicle sales sporting an embarrassingly high 157 gm/km emissions rating.

Consultant McKinsey wrote: "Projections for Europe indicate that automakers would need to sell up to 2.2 million electric vehicle (EV) units in 2021 alone to meet their fleet CO2 targets. That would be a steep ramp-up of EV sales in fewer than two years and equivalent to global EV sales in 2018. This is a big task not only for the automotive industry but also for the associated industries." Therein lies one of the major problems for the German automobile manufacturing industry, its vendors, and ultimately the German government. The German auto industry employs 800,000 workers directly, with many more associated with parts suppliers.

Describing the challenges facing the German automobile industry, CEO Volkmar Denner of parts supplier Bosch said the new EU emission rules “mean the end of the classic internal combustion engine with corresponding effects on employment in the companies concerned.” After a poor 2019, Bosch sees continuing declines in sales at least until 2025. Bosch has recently announced 3,500 jobs cuts. Automobile manufacturer Volkswagen’s Audi division announced it would cut 9,500 of its 61,000 jobs in Germany. Daimler AG has said it will cut 10,000 workers from its global 300,000 workforce with most of the cuts being white collar management employees. The company has an agreement with its German assembly line unions preserving their employment until 2029. The job cuts are a necessary step towards reducing total manufacturing costs in an attempt to remain profitable in a lower volume automobile market.

Germany’s need for EVs will be huge if the country is to meet the EU emissions goal, as well as the country’s 2030 climate plan. The number of EVs registered in Germany should reach 7-10 million by 2030, says the government in its plan. To reach this target, public charging points for EVs will increase to one million, with public funding provided for the expansion until 2025. Auto manufacturers and energy companies will be encouraged to expand the charging infrastructure as well. All service stations in Germany will be ordered to install charging points and the construction of fast-charging points can be counted as a decarbonization effort for the oil industry. The government will extend the tax subsidies for passenger cars with electric, hybrid or hydrogen/fuel cell propulsion systems. The subsidies will also be increased for cars costing less than €40,000 ($44,334). Tax allowances for company EVs or plug-in hybrid cars will be extended to 2030. The German motor vehicle tax will change and be based on emissions per kilometer for new registrations beginning in 2021.

Another challenge for auto workers is that EVs have substantially fewer parts than ICE cars. While the steering and suspension systems are similar, there are roughly 2,000 parts in the transmissions and drive trains of ICE vehicles versus maybe 95 in an EV. This design revolution will mean a smaller auto parts manufacturing business, as well as fewer repair and maintenance dollars for car dealers, who generally make most of their profits from behind the sales showroom.

Many aspects of the automobile industry are facing systemic changes. Mr. Denner of Bosch suggested that the employment effects of the shift to EVs may require German government support, just as it is proposing to aid the people and economies in the nation’s coal producing regions. Although Bosch has added jobs globally over the past few years to meet new demands from digitalization and e-mobility, the long-term trend of automobile employment is downward.

The employment problems in Germany have emerged as an issue in the United States, too. General Motors has had to agree to various union demands to protect manufacturing employees in order to gain greater flexibility for managing its assembly capacity in the face of a shrinking automobile market. With EVs having fewer parts and requiring less time for production, auto manufacturers will be faced with surplus plants and excess labor. Is it possible that U.S.-made EVs will follow crude oil and natural gas as a new exporting business?

One new trend we have found in researching this article is the growing focus on hydrogen as the new liquid vehicle fuel. It is thought that surplus wind and solar power can be used to break down water into its component molecules, producing liquid hydrogen that can be stored and used to power vehicles. This would be another way to offset the need to build battery storage for surplus clean energy, and possibly a cheaper way to use the surplus power, rather than paying providers to not generate power. It may also be a way to avoid having to revamp the transportation fuel infrastructure.

Another aspect of the switch to an EV-dominated fleet will be how the electricity to power them will be generated. In the U.S., low-cost natural gas continues to push coal and nuclear power out of the electricity generation equation. Cheap natural gas has expanded, and continues to expand, the nation’s liquefied natural gas (LNG) export business. As the number of EVs sold and in the fleet grows, electric power needs will increase and the share produced by burning natural gas should increase, too. Will renewables eventually cap the share of the generation market supplied by natural gas? Could this hurt natural gas prices in the long-term? If its future growth depends totally on weather and LNG export markets, the netback from world gas markets after liquefaction and transportation charges will keep wellhead prices low if we are to remain a player in the global LNG market. However, if the slowdown in oil drilling in the Permian Basin with its high associated gas content causes national gas output to cease growing, gas prices are likely to increase creating economic challenges in many of the end markets that natural gas is counted on to supply. There certainly are no answers right now, instead there are many “What if…?” questions.

Exhibit 13. How Incomes And Cars Interact

Source: WSJ

An economist with the IMF, Gita Gopinath, discussed a macro trend that seems not to be unfolding as economic theory would suggest. That theory is that car ownership tends to rise with per capita income. As incomes in poorer regions converge with those of richer countries, automobile sales should rise. But it isn’t happening “at the speed we thought, so the demand for durable goods like cars hasn’t come about,” said Ms. Gopinath. She pointed out that the average Brazilian was 77% richer than the average Chinese in 2008, but after a decade of stagnation Brazilians are now 16% poorer. Not surprisingly, Brazilian automobile sales peaked five years ago. Will that trend change if the Brazilian economy overcomes its holdbacks, and does that mean more Brazilians will own vehicles or multiple vehicles in the future under that scenario? Brazil was the eighth largest automobile market in 2018, with roughly 2.5 million cars sold. It is a couple of hundred thousand cars behind France, and an equal amount ahead of Italy. With the economic, social, political and population trends in those two European countries, Brazil, if it can resolve its economic inequality issues, could easily become a much more important global automobile market, potentially helping to boost its economy. It is questions such as these that have to be internalized into the thinking of automobile manufacturers as they strategize about their future business models.

That is why the IHS Markit research project is so interesting. The first iteration in 2017 concluded in its baseline model that mobility as a service (MaaS) will grow, eroding the need for personal car ownership.

Exhibit 14. Miles Traveled Will Continue To Grow

Source: IHS Markit

The net of this trend is that vehicle miles traveled will continue to grow, but the new MaaS market offers a significant opportunity for its fleets to be EVs. That trend, coupled with increased interest by consumers in purchasing EVs, will kick-off an acceleration in the penetration of EVs in the global vehicle fleet, but not really having an impact until the middle of this decade.

Exhibit 15 EV Share Of Vehicle Fleet Grows Later

Source: IHS Markit

These two trends translate into a fuels market where gasoline consumption reaches a plateau at the start of this decade and remains flat throughout it. Diesel fuel consumption begins declining at the beginning of the 2020s, largely driven by the diesel emissions cheating scandal that has turned customers away from these vehicles, and automobile manufacturers stopping producing them. Electricity consumption for the growing EV fleet emerges at the start of the 2020s, but doesn’t become meaningful until the end of the decade. Alternative vehicle fuel also grows during the early 2020s, but then remains flat through the 2040 forecast period. Total vehicle fuel consumption peaks about 2025 and is lower by 2040, but not by an appreciable amount.

Exhibit 16. Fossil Fuels Have A Long Future Ahead

Source: IHS Markit

The criticism of this scenario by climate change proponents is that it fails to embrace the speed with which EVs will penetrate the global automobile market. We believe they fail to appreciate that EVs are, and will remain largely a niche vehicle option, and likely won’t become ubiquitous until battery charging issues are more fully addressed. The preliminary data from InsideEVs shows global EV sales fell 4% last year, and 9% in the U.S. Regardless, EVs will gain market share at a time when total vehicle sales are likely to be reaching a plateau and possibly are about to go into a decline. Forces such as increased urbanization, offering greater market potentials for MaaS and mass transit, alternative liquid fuels such as hydrogen, and technologies like fuel cells will mix with population and ageing trends and income inequalities to make the automobile market a much more complex business model to decipher. Turmoil in the automotive sector will not be good for economies given its significant impact along with its employment importance. Add auto industry executives to the large number of energy executives who are now wrestling with understanding how their markets are changing and how different their futures may be than what they were thinking only a few years ago.

Things We Learned About Energy Since The Last Musings Issue

Ships With Exhaust Scrubbers Are Smiling (Top)

As we have written numerous times, the idea that oil prices were going to explode due to the implementation of IMO 2020 low-sulfur fuel restrictions for the global shipping industry were not well founded. One of the solutions for shippers was to install exhaust gas scrubbers and continue to use high-sulfur fuel oil, banking on the cost differential with low-sulfur fuel oil or other compliant fuels producing a reasonable payback period for the capital investment. Based on fuel oil price spreads in early 2019, the estimated payback for a $2.5 million scrubber investment was estimated at 3-3.5 years. Given what has happened in the fuel market so far this year, a new estimate of the payback has it potentially down to a year or less. Obviously, there are lots of assumptions in the calculations, but the reality has been that those shippers that opted for scrubbers are smiling at the cost-benefits they are having, especially versus competitors. It is especially true as the marine transportation market is being materially impacted by reactions to the coronavirus. Once we get past this episode, the fuel markets will rebalance and the payback times will likely increase, but it seems that they will not drive them beyond what was projected in early 2019.

Energy And Tobacco Are Not Equivalent (Top)

Last Friday morning, Chevron Corp. Chairman and CEO Mike Wirth was interviewed on CNBC’s Squawk Box show. He was asked about the challenges to fossil fuels from today’s youth who often equate the damage from carbon emissions as equivalent to that of tobacco. Mr. Wirth destroyed that argument in a few sentences. He said: “The reality is the world runs on the energy system we have today. I think the comparison to tobacco is not an appropriate one at all. If tobacco use were ceased today, I think the world would be just fine. If we ceased use of all hydrocarbon products today, the world would not be fine, and I think that’s the reality.” Amen. However, that doesn’t absolve the energy industry stopping working for a cleaner environment.

Why We Love Texas – From A Friend (Top)

JUST TEXAS

Pep, Texas 79353

Smiley, Texas 78159

Paradise, Texas 76073

Rainbow, Texas 76077

Sweet Home, Texas 77987

Comfort, Texas 78013

Friendship, Texas 76530

Love the sun?

Sun City, Texas 78628

Sunrise, Texas 76661

Sunset, Texas 76270

Sundown, Texas 79372

Sunray, Texas 79086

Sunny Side, Texas 77423

Want something to eat?

Bacon, Texas 76301

Noodle, Texas 79536

Oatmeal, Texas 78605

Turkey, Texas 79261

Trout, Texas 75789

Sugar Land, Texas 77479

Salty, Texas 76567

Rice, Texas 75155

Pearland, Texas 77581

Orange, Texas 77630

Plum, Texas 78952

And top it off with:

Sweetwater, Texas 79556

Why travel to other states? Texas has them all!

Detroit, Texas 75436

Cleveland, Texas 75436

Colorado City, Texas 79512

Denver City, Texas 79323

Klondike, Texas 75448

Nevada, Texas 75173

Memphis, Texas 79245

Miami, Texas 79059

Boston, Texas 75570

Santa Fe, Texas 77517

Tennessee Colony, Texas 75861

Reno, Texas 75462

Pasadena, Texas 77506

Columbus, Texas 78934

Feel like traveling outside the country?

Athens, Texas 75751

Canadian, Texas 79014

China, Texas 77613

Egypt, Texas 77436

Ireland, Texas 76538

Italy, Texas 76538

Turkey, Texas 79261

London, Texas 76854

New London, Texas 75682

Paris, Texas 75460

Palestine, Texas 75801

No need to travel to Washington D.C.

Whitehouse, Texas 75791

We even have a city named after our planet!

Earth, Texas 79031

We have a city named after our state

Texas City, Texas 77590

Exhausted?

Energy, Texas 76452

Cold?

Blanket, Texas 76432

Winters, Texas 79567

Like to read about History?

Santa Anna, Texas 76878

Goliad, Texas 77963

Alamo, Texas 78516

Gun Barrel City, Texas 75156

Robert Lee, Texas 76945

Need Office Supplies?

Staples, Texas 78670

Want to go into outer space?

Venus, Texas 76084

Mars, Texas 79062

You guessed it. It’s on the state line.

Texline, Texas 79087

For the kids…

Kermit, Texas 79745

Elmo, Texas 75118

Nemo, Texas 76070

Tarzan, Texas 79783

Winnie, Texas 77665

Sylvester, Texas 79560

Other city names in Texas, to make you smile…

Frognot, Texas 75424

Bigfoot, Texas 78005

Hogeye, Texas 75423

Cactus, Texas 79013

Notrees, Texas 79759

Best, Texas 76932

Veribest, Texas 76886

Dime Box, Texas 77853

Old Dime Box, Texas 77853

Telephone, Texas 75488

Telegraph, Texas 76883

Twitty, Texas 79079

And our favorites…

Cut and Shoot, Texas 77303

Gun Barrel City, Texas 75156

Hoop And Holler, Texas 77327

Ding Dong, Texas 76542 and, of course,

Muleshoe, Texas 79347

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.