Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

Another Record Drilling Year Projected for Canada

The Petroleum Service Association of Canada (PSAC) released its 2006 drilling activity forecast on October 26 calling for another record year. The industry association is projecting that 25,290 wells, based on a rig released basis, will be drilled in

The projected increase in wells to be drilled is due almost entirely to growth in wells drilled for natural gas from coal (NGC). The drilling forecast calls for about 20,000 wells to be drilled in

This year has presented a real challenge for the petroleum industry. PSAC anticipated in its October 2004 drilling forecast that the industry would drill 24,035 wells in 2005, about an 8% year-over-year increase. That increase was driven by a 2,000 well gain in NGC wells from 1,000 to 3,000. After early winter, the industry was on track to drill slightly more wells than forecast and PSAC inched up its 2005 well forecast to 24,075 wells. The new forecast reflected a 6% gain from the 2004 estimated well count of 22,696 wells. However, spikes in temperatures impacted rig mobility in early spring and later the rains came producing flooding in southern

What is interesting to note is the trend in the number of wells drilled and the forecasted count. As shown by Exhibit 1, the industry drilled about 5,000 wells per year from the early 1980s to the early 1990s. Then from 1993 through 1999, the industry about doubled the average number of wells drilled per year. Since then, the well count has climbed fairly steadily into the mid teens thousands of wells and is now up into the low 20,000s wells. If the drilling industry continues to add rigs to the fleet, the well completion count should continue to climb. Additionally, as NGC-related wells increase as a percentage of total wells drilled, the industry may be able to boost its drilling pace faster since these wells tend to be fairly shallow and can be drilled quickly. The last trend that might help boost the future well count would be continued progress in getting the industry to shift to drilling on a year-round basis.

Exhibit 1. Canadian 2006 Well Forecast

Source: PSAC; PPHB

Another important consideration for understanding the dynamics of the Canadian oilfield service market is the trend in the type of wells drilled. As shown in Exhibit 2, the history of well completions, as reported by the Canadian Association of Oilwell Drilling Contractors (CAODC), shows a meaningful shift away from drilling oil wells and toward drilling more natural gas wells. This is not surprising given the significance of natural gas in the

Exhibit 2 Gas Wells Becoming More Important

Source: CAODC; PPHB

Oilfield service companies and contract drillers who have reported third quarter financial results characterized activity in

Another Article Questions Saudi Reserves

The New York Times on October 27 carried another front page story expressing doubts about

Once again, however, the petroleum industry appears to be “tone deaf” to the public’s anger over high oil and gas prices. Now, however, the public’s outrage has reached the halls of Congress. Last Thursday, Senate Majority Leader Bill Frist (Tenn.-R) asked three Senate committees to hold hearings on high energy prices and oil company profits. Those hearings are scheduled for November 8, and will provide another platform for politicians to rail against oil company officials about their lack of empathy with the pain consumers are feeling at the gasoline pump.

Earlier last week, the House Republican leadership, instrumental earlier this year in helping engineer passage of two energy bills favorable to the industry, called for the industry to return the favor and begin building refineries and taking other steps to increase fuel supply and lower gasoline prices. Even the Bush Administration got into the act. U.S. Energy Secretary Sam Bodman told a Senate Energy Committee hearing, “These companies are turning in record profits – they have a responsibility to expand refining capacity.”

Political pressure on the oil companies to ramp up their refinery investment will likely increase, however, there is little that can be done to ease the current product tightness. A new refinery in the

The bigger question for the petroleum industry is the reverse of the problems currently contributing to high gasoline and heating oil prices. That is, the lack of refining capacity is supposedly driving up product prices, but what happens if we expand capacity and find that there is no additional crude oil supply? That scenario has to be considered by the oil industry as it contemplates where to invest its cash flows. Thus, the latest New York Times article questioning

In the article, the history of discussions between

Increasing

Last year, Mr. Price questioned future reliance on Saudi capacity and wanted to know from his former colleagues how they reached their estimate of more than 150 billion barrels of spare oil. Mr. Price stated that twenty years ago, a detailed study by Aramco (the oil company jointly owned by four major oil companies) geologists found little in the way of undiscovered oil resources. So when Mr. Price met with Mr. Saleri last year, he was told that the basis for the higher oil figure was a 2000 global study performed by the United States Geological Survey (USGS) that estimated

As a result of concern about the validity of the USGS reserve study, the United States Energy Information Administration (EIA) has backed away from its long-term estimate that Saudi oil production could grow to 20+ million b/d. If Saudi can boost its productive capacity to 12 million to 15 million b/d, it would provide significant relief to world oil markets. Questions remain, however, about how long it might take the kingdom to reach that production target. Additionally, there is the question of what type of incremental crude oil reserves will be brought into production. Whether the new crude oil reserves will be light or heavy, or contain significant sulfur or not; will influence what type of refining capacity the world needs to build. Therefore, it is understandable that oil companies are reluctant to make multi-billion dollar refinery investments without knowledge of the specific types of crude oil that will be refined.

If the political process is allowed to progress to its logical conclusion, the oil companies might be forced into agreements to build refineries where they are not needed and to process crude oil that may not be available. That is a way to permanently depress returns on investment, a condition the industry is trying to avoid. Unfortunately, oil industry regulatory politics have a history of producing this type of outcome.

Reed Rig Census Shows Interesting Data

The latest Reed Hycalog survey of

Exhibit 3. Active and Total Rig Fleets Grow

Source: Reed Hycalog, PPHB

When you look at the pattern of yearly gains and losses for the domestic rig fleet, as shown in Exhibit 4, it mirrors the health of the oil and gas industry. The graph shows how the fleet’s growth exploded during the bullish industry conditions of the late 1970s, only to collapse with the drop in oil prices in the 1980s. That decade’s fleet contraction reflected the demise of many small contractors that were formed and purchased their equipment at the industry peak in the late 1970s.

Exhibit 4. Rig Fleet Changes Mirror Industry Health

Source: Reed Hycalog; PPHB

Another interesting trend is that the number of rig contractors has climbed for a second straight year following a 17-year decline. According to the survey, there are 226 contractors, an increase of 13 from 2004. Between 1987, the first year of the survey reporting the number of rig contractors, the count had fallen from 690 to 179 in 2003. That trend was not surprising since the consolidating forces at work due to weak industry activity, ageing managements/owners and the financial pressures from low fleet utilization, weak pricing and higher costs associated with increased H, S, E. demands from clients. The improved drilling industry financial environment will probably contribute to the formation of additional rig contractors over the next several years, along with an expanding rig fleet. Growth of the fleet and the number of new contractors should be viewed from the perspective of the experience of the 1970s and 1980s.

Exhibit 5. Number of Contractors Growing

Source: Reed Hycalog; PPHB

The last trend we found intriguing was the number of rigs owned by operators. While the 64 operator-owned rigs in 2005 were down from the 92 listed for 2004, we find the change surprising, although it may merely reflect the timing of a sale of certain operator-owned rigs. However, when we looked at prior years, the significance of operator-owned rigs was clearly evident as there were 79 operator-owned rigs in both 2000 and 2001, and 71 rigs in 2003. The rig survey was not done in 2002. When you look at these numbers, you have to go back to 1964 to find when there were more operator-owned rigs. That year the industry had 108, and it was in a period of declining operator-owned rig ownership that started with the 1955 survey when there were 400 operator-owned rigs. That early industry period reflected an environment when operators often maintained their own drilling departments and operated drilling rigs as part of an effort to train drilling engineers and control drilling costs. The last major oil company to operate a drilling department and rigs was Exxon that shut down its effort in the mid 1970s.

Exhibit 6. Operator-owned Fleet Growing

Source: Reed Hycalog; PPHB

In 1955, operator-owned drilling rigs accounted for 12.5% of the entire rig fleet. Today, that class of rigs accounts for only 3.2% of the fleet, but it had been averaging about a 4.5%-4.8% share in the 2000s. Will concern about rig shortages prompt operators to boost their ownership of drilling rigs? This is an interesting question, but except for large geographic areas that are the focus of active exploration and development, we suspect the inefficiencies of managing a drilling rig fleet will drive operators away from rig ownership, much as these conditions did in the 1970s.

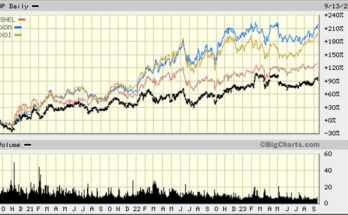

Forbes Small Cap Stars

The October 31, 2005, issue of Forbes magazine listed their 200 best-run small companies. According to our count, there were 17 oil and gas and oilfield service companies included among those select 200 companies. The magazine story said that there were 16 energy companies, so we wonder which company on our list was not included on their list. Exhibit 7 lists the 17 energy companies we identified, along with their financial statistics as reported by Forbes. The growth and return measures were what determined the selection of companies. Of the energy company universe, only three companies did not have a five-year, double-digit return on equity or sales growth. Only two companies did not have five-year, double-digit earnings per share growth. Only one company, Lufkin Industries (LUFK-NASDAQ), made the list despite generating both a mid single-digit return on equity and five-year sales growth. However,

Besides

We were impressed that about half (8 of 17) of the companies making the Forbes list made it last year. Given the cyclical performance of the energy business over the past few years, the performance of these companies is that much more impressive.

Exhibit 7. Forbes Small Energy Company Universe

Source: Forbes; PPHB

Pipeline Delays Could Cost Canadians C$57 Billion

At a recent conference on North America natural gas strategies held in

CEPA commissioned Angevine Economic Consulting to extend the methodology used by Energy and Environmental Analysis (EEA) in their July 2004 study prepared for the Interstate Natural Gas Association of America (INGAA) on the

To understand, and better appreciate, how the study was done, it is necessary to examine the main drivers in the methodology of the EEA study. The key gas industry drivers are the prices for oil and coal, the principal fuels that compete with gas, and the rates of economic and industrial production growth. The study assumed that real U.S. GDP and

In both the Base Case and the Delay Case, the real (2004 dollar) refiner crude oil acquisition cost was assumed to average $50.17 per barrel in 2005, falling only to $46.74 per barrel by 2010 and then gradually declining to $41.76 per barrel in 2025. The real price of coal in 2004 was $1.37 per million Btu (MMBtu). That price was assumed to increase by 0.09% per year from 2004 to 2025, lifting coal prices to $1.39 MMBtu. From all these variables, the model solves for the monthly price (market clearing price) for natural gas that simultaneously balances supply and demand in regional markets.

The EEA Base Case estimated the amount of interregional pipeline capacity to be built over the period to 2025. That volume is substantial; however, beyond the next couple of years, it is almost impossible to forecast which specific pipeline capacity expansions and new pipeline projects will be constructed. The EEA made general projections of new capacity additions in accordance with developments between adjacent market price centers. Most of the new capacity will be related to the need to tie in new supply areas, including the Mackenzie Delta and the Alaskan North Slope, to markets. In addition, pipeline infrastructure will be needed to accommodate increased LNG imports.

The EEA study assumed that from 2005 to 2025, approximately 4.5 billion cubic feet per day (Bcf/d) of additional gas pipeline capacity will be needed out of

The conclusion of the EEA study was that, including both regional and interregional pipelines, the natural gas industry will need to construct more than 45,000 miles of pipelines to supply the gas needs of

With respect to the timing of the construction of these major new northern pipelines, the Base Case assumed that the Mackenzie Gas Pipeline would begin operation with 1 Bcf/d of throughput in November 2010. The first full year of operation would be 2011. Gas throughput volumes would slowly rise, reaching 1.2 Bcf/d in 2016 and 1.5 Bcf/d in 2022. The Alaska Pipeline would have a constant 4 Bcf/d throughput and would commence operation in November 2014. The first full year of operation would be 2015.

Under the Delay Case, new or expanded infrastructure needed to deliver gas from new producing regions and the northern frontier to the various regional markets is not put into place until two years later than projected in the Base Case. The construction of new LNG terminals and associated pipelines is also assumed to lag by two years. Certain projects that are already under construction, or are associated with planned near-term expansion projects, are assumed not to be delayed.

The price increase for Henry Hub gas prices due to the two-year construction delay was an average of a $1.21 per MMBtu (a 14.6% increase), or $1.02 per MMBtu (a 16.5% increase) in constant 2004 dollars. The impact would be felt almost immediately and continue for the next 15 years, or until 2017 when the first full year of operation of the Alaskan Gas Pipeline project is expected to be on-stream. The estimated increase in gas prices in

Exhibit 8. Price Increases From Construction Delays

Source: CEPA

One of the results of the infrastructure construction delays is a boost for gas prices. As one would expect, there would be a resulting decline in natural gas consumption as consumers conserve and gas users with the ability to seek out alternative supply sources do so. Given the greater flexibility of large industrial gas users compared to residential customers to switch to alternative fuel sources, the fall in gas demand is relatively greater. Commercial gas consumers will also be impacted, but their impact will fall between that of industrial users and residential consumers. Overall,

Exhibit 9. Gas Consumption Impact of Pipeline Delays

Source: CEPA

Despite the fall in demand, the impact of higher gas prices more than offsets the reduced gas volumes. Because of the imbalance of gas consumption by geographic region in

Exhibit 10. Regional Cost Impact of Pipeline Delays

Source: CEPA

The purpose of the CEPA study was to piggy-back on the results of the EEA study for INGAA. The combined economic impact from higher natural gas prices as a result of a two-year delay in the construction of the pipeline infrastructure of close to $200 billion over the next 20 years should get the attention of politicians and regulators who are involved in sanctioning these various projects. There are probably other financial and economic impacts that are not captured in these studies since they were not constructed to measure the entire economic impact of the pipeline construction delays. However, if a $200 billion cost to the North American economies is not a motivating force for getting these projects moving, then we probably have a bleak future for meeting our energy needs.

Oil Company Consumer Response

Last week, Chevron (CVX-NYSE) announced it would provide gasoline discounts to consumers and forgive payments owed by gasoline marketers as part of a program to help Gulf Coast areas devastated by the recent hurricanes. Qualified customers using Chevron and Texaco credit cards in selected parts of

We have to believe, and have actually heard, that petroleum companies are concerned about the political reaction to their current profitability. While Chevron reported only a 12% year-over-year increase in third quarter profits, the political storm in

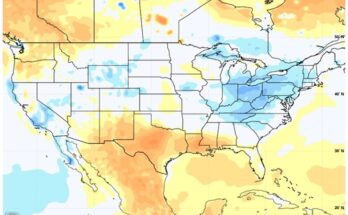

Oil company managers need to remember that it was only in the early 1980s that President Ronald Reagan was able to decontrol energy prices that had been shackled by regulations since the mid 1970s in direct response to high oil prices such as we have now. We all know the mess the price and allocation regulations made of petroleum markets and how they reduced the industry’s profitability, but another generation of politicians preparing to face the electorate next year may be willing to pander to the voters. It wouldn’t be the first time. The industry needs to be sensitive to the changes in the political mood following oil company earnings reports, especially given the continued high gasoline and heating oil prices and the early arrival of winter weather.

Need A Speaker or Discussion Leader?

Maybe you have been reading this or past issues of Musings From the Oil Patch and have found articles provocative or enlightening. Possibly you would like to have these subjects explored in greater depth in a presentation to your management team or your board of directors, or possibly to an organization you are a member of. The author is available to speak or lead a discussion. Give us a call.

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.