- A Refreshing Pause Or Something More Ominous?

- Everyone is Worried about Electricity

- China Filling its New Strategic Storage Tanks

- Shell Canada: Start of a Trend or a One-off Deal?

- A Boost for the Renewable Natural Gas Industry

- UK a Permanent Net Oil Importer Starting Next Year?

- FERC Rule on Pipeline ROE Scares Industry

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

A Refreshing Pause Or Something More Ominous?

The

The land rig count started this year at 1,384 with the near-month natural gas futures price at $9.63 per Mcf. As the rig count climbed by 20% to 1,664 rigs, reached during the week of September 22, natural gas prices had dropped by more than 50% to $4.63. Producers were becoming quite concerned about the trend in gas prices and several producers announced they were shutting in gas production that had not already been hedged earlier at substantially higher prices. As gas prices fell, producers began slowing their drilling and well completion activity that was reflected after an appropriate lag in the rig count that has declined roughly two percent from its peak.

Natural gas prices have strengthened in the last couple of weeks as we have come out of the “shoulder season” marked by weak demand due to moderate weather. The early snow storm in upstate New York and cool weather across the Northeast region, coupled with snow in the Rockies, have awakened commodity traders to the fact that once again we will have a winter this year. The new troubling development was the release of the early estimate of third quarter 2006 U.S. GDP. The estimate was for 1.6% annual growth in the quarter, well below the consensus expectation of 2.2%. If this early estimate holds through the various revisions, people will have to wonder about the impact of weak economic activity on energy demand, and importantly if this weak economy lasts into 2007.

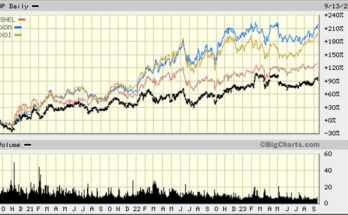

Exhibit 1. Oilfield Activity Has Paused

Source: Baker Hughes, EIA, PPHB

Weak commodity prices and flattening oilfield activity may be eroding oil service company pricing power. Chesapeake Energy Corp. (CHK-NYSE), in its quarterly earnings conference call with analysts, discussed a letter it had sent to over 4,000 oil service providers indicating that the company would no longer pay for fuel surcharges and was requesting consideration of a cost rollback of 10% to 20%. The company noted that the reception to its requests has been varied, but clearly the pressure on service companies to stop and/or rollback price increases is building. As that works through the system, the current fat profit margins of the oilfield service companies will be trimmed.

On its earnings conference call last week, Nabors Industries (NBR-NYSE) talked about the flattening in the expansion of its rig margins. More importantly, management pointed out that it did not anticipate rig margins improving anytime soon, but rather it would mostly boost domestic earnings from additional rigs working with a little help from the rollover of lower-priced rigs to higher rate contracts, but this pricing leverage was quite small and would not drive overall rig pricing and/or earnings materially.

For oilfield service companies, the pause in oilfield activity has been greeted with relief since it has eased the pressure on them to secure and train additional workers and sustain equipment utilization at peak levels. For producers, the pause is giving them the confidence to push back on oilfield service cost pressures. Even though gas prices have recently recovered, overall oilfield activity will likely suffer more as we head to toward year end due to the regional restrictions on winter drilling in the

Everyone is Worried about Electricity

The recent slump in oil and gas prices gave consumer budgets some relief. Wall Street was immediately trying to figure out where they were going to spend this newfound windfall from lower gasoline and home heating oil prices. Wall Street was even talking about the rollbacks in electricity rates by generators who had been granted rate hikes earlier in the year to help cover exploding fuel costs. But what hasn’t received a lot of attention is the crying need for huge investments in additional generating and transmission capacity to assure adequate electric power in the future. What is equally surprising is that this is not a U.S.-only issue, but Europe and

In 2005 and early 2006, the margin between electricity supply and demand in

In the

This summer in the

The North American Electric Reliability Council (NERC), a nationwide industry self-regulatory body established in 1965 following the 1964 great Northeast blackout, recently published its annual report on the adequacy of the country’s electric power supply. NERC has assumed new powers under the 2005 Energy Policy Act giving its report greater stature. According to the report, the power that could be generated or transmitted would drop below the minimum regional target levels meant to ensure reliability on peak days in

The report recommends that utilities should be encouraged to pursue financial incentives for customers to cut use during peak hours, thereby lowering demand for new power plants and transmission lines. The financial incentives could reward customers for installing more efficient equipment or, more drastically, reward a factory for closing on a day when electricity supplies are expected to be tight. According to the report, direct control load management and interruptible demand programs represent about 2.5% of summer peak demand (20,000 MW) in the U.S. and about 2.5% of winter peak demand (2,500 MW) in Canada. New or expanded demand response programs and initiatives could further reduce peak demands.

NERC is predicting that electric power demand will increase over the next 10 years by 19% (141,000 MW) in the United States and by 13% (9,500 MW) in Canada, but projected resources would increase by only 6% (57,000 MW) in the U.S. and by 9% (9,000 MW) in Canada. Utility executives are concerned about running out of generation capacity and believe that the public is unaware of how close parts of the country are to running out of power. However, some industry executives urge caution about embarking on a massive building effort. Peggy Fowler, CEO of Portland General Electric (POR-NYSE) said, “We all say we need energy. But in the past, we have been terrible as an industry at predicting how much.” She points out that past forecasting mistakes contributed to the economic problems the industry has struggled with over the past few years. Decisions made today about building new generating capacity carry implications for customers 50, and maybe 100 years in the future.

Amory Lovins, head of the Rocky Mountain Institute, says, “Utility executives are talking too much to each other and not paying attention to what is going on in the world market.” He points to the growing share of the world’s electricity demand met by co-generation plants that produce electricity and hot water or steam, distributed generation, wind, photovoltaics and biomass. This “micropower”, as Lovins calls it, is meeting more than half of

Michael Chesser, CEO of Great Plains Energy (GXP-NYSE) in

Given the growing culture in the

China

Xu Dingming, vice director of the State Energy Office under the State Council, recently said that the government has started filling its new strategic oil storage tanks in

According to Dow Jones, Xu Dingming indicated that local oil production was being used to fill the storage tanks, although other reports are that

In this initial stage,

In addition to its strategic crude oil storage facilities,

For the first nine months of 2006,

Spending on crude oil and natural gas production increased 19.3% for the first nine months of 2006 over 2005. Investment in coal mines was up 36.4% in the period. Net crude oil and refined product import volumes in September grew by 32.1% over last year and by 18.8% over the prior month to 3.9 million b/d. Crude oil imports were 3.3 million b/d, rising by 24% over September 2005 and 2.4% above the prior record in January.

As shown in Exhibit 2, the monthly volume of crude oil and refined products imported by

Exhibit 2. Refined Products Imports Growing

Source: CSA

The greatest challenge for observers of the petroleum industry is to understand

Due to this inventory uncertainty, forecasts of demand growth vary widely. For example, the estimates for

Exhibit 3. China 2006 Demand Forecasts Vary Widely

Source: CSA, PPHB

Shell Canada

On Monday, October 23, Royal Dutch Shell (RDSA-NYSE) announced that it had advised the board of directors of Shell Canada Limited (SHC-TSE) that it is intending to offer to buy the minority interests in the company it doesn’t own for a cash price of C$40 per share, a 22% premium over the closing stock price on the previous Friday. Does the rationale for this deal reflect the start of a consolidation trend within the energy industry or merely a one-off transaction for Shell? Either answer presents interesting implications for the oil industry.

Royal Dutch Shell recently has gone through possibly the most challenging period in its corporate history over the past three years as a massive reserve write-down in 2004 due to questionable management of the company’s E&P operations was followed by poor exploration success in 2005. The result of these developments is that new management is now running the company; its former dual, nationalistic corporate structure has been jettisoned; and the company has become more aggressive in responding to changing industry conditions. These changes have not yet produced a significantly modified corporate business plan, but possibly the bid to buy the remainder of Shell Canada is a first step.

As the third largest independent oil company in terms of reserves behind ExxonMobil (XOM-NYSE) and BP (BP-NYSE), Royal Dutch Shell has struggled to recover from its reserve debacle. Moreover, the company has been hit by production challenges in certain parts of its global operations, most particularly in

Shell

Since the oil sands developments require significant infrastructure and employ mining-type operations, they are high cost projects. Their commercial success is partially attributable to the rise in global oil prices that has more than offset the increases in construction and operating costs of these mining projects. For Royal Dutch Shell, securing complete control of these resources would improve the company’s reserve picture and, eventually improve its financial outlook. Profitability would be further enhanced by organizational changes that could be made with the combination of the two organizations.

While it is clear that the successful acquisition of the minority interest in Shell Canada would improve the results of Royal Dutch Shell, an interesting question is whether this move is at the forefront of an emerging industry consolidation phase. If the major independent oil companies are stymied in their efforts to grow as a result of substantial global resource opportunities being off-limits due to state ownership and with numerous other governmental regimes being unfriendly, then acquiring undervalued companies that hold portfolios of exploration and development opportunities becomes an attractive option. Shell

The last time Royal Dutch Shell tried to buy one of its daughter companies was in 1986 when it launched an effort to buy the remaining shares in Shell

People who believe this latter scenario is driving the Royal Dutch Shell move expect that the company would next move to try to buy out Shell Canada’s partners in its oil sands projects, including Western Oil Sands (WTO-TSE) and possibly Chevron

Starting in the spring of 2005, Petro-Canada (PCZ-NYSE) acquired a 60% interest in the Fort Hills oil sands project from UTS Energy Corp. (UTS-TSE). That deal was followed by two separate transactions involving Chinese state-owned oil companies acquiring minority stakes in oil sands projects. In August 2005, Total S.A. (TOT-NYSE) bought out Canadian oil sands developer Deer Creek Energy Ltd.

Earlier this year,

More important, however, is the issue of whether this deal sets off a general producer consolidation wave with major Independent Oil Companies (“IOC’s”) buying large independents such as Anadarko Petroleum (APC-NYSE), Apache Corp. (APA-NYSE) and Devon Energy (DVN-NYSE) for example, all of which possess substantial production, reserves and resource potential. That would help the IOC’s in their efforts to sustain their production profiles and, given the large share repurchases they have been undertaking, enable them to grow their per-share reserve and production measures, which influence stock market valuations. The downside to entering a producer consolidation phase is that the uncertainty caused by the deals often results in a slowdown in oilfield activity, not a good development for oilfield service companies.

A Boost for the Renewable Natural Gas Industry

Cargill, Inc., the farm-commodity processing giant, is embarking on a venture to turn livestock manure into methane gas. This should provide a boost to the fledgling renewable natural gas industry. Cargill is joining with Environmental Power Corporation (EPG-AMEX), a leader in the renewable biofuels industry, in a strategic alliance involving Environmental Power’s Microgy Inc. subsidiary.

Microgy builds, owns and manages facilities that produce renewable natural gas or other energy from food and animal waste. The company holds an exclusive license in

Cargill has agreed to recruit farmers whose livestock operations are large enough to generate a reliable supply of manure for the anaerobic digesters that Environmental Power will build. A digester uses microorganisms to convert manure from about 1,000 cows into methane. A digester can cost about $1 million to construct.

Microgy is currently building a multi-digester biogas production and gas conditioning facility near

The

Several years ago we wrote in a Musings about the potential energy that could come from harnessing the flatulence of farm animals. And in our last issue we discussed how the disruptive technology of the internal combustion engine eliminated the need for urban horses and mules as power sources and solved the growing animal waste problem engulfing American cities at the turn of the 19th Century. As the old saying goes: What goes around comes around. Maybe we are witnessing the birth of a new renewable fuel supply that will reduce our future hydrocarbon demand while solving the animal waste problem for farmers.

Currently, Microgy operates three digesters in

per day. If all 1,200 large animal feeding operations produced the equivalent output of the Huckabay Ridge facility, then the country would be generating approximately 15.2 million gallons of heating oil per day, or almost 83% of historical heating oil consumption. Alone, this would not significantly alter our energy consumption pattern, but as a step toward reducing our dependence on hydrocarbon fuel, it would be a meaningful step down that path. So, who from the oil patch will be the first to wade into this alternative energy industry?

UK

The UK-based Oil Depletion Analysis Centre (

The DTI September monthly report about oil production and consumption shows that total indigenous UK production of crude oil and NGL’s in the second quarter of 2006 was 13.2% below the year ago quarter. Two new fields started production during the past year, but they were unable to make up for the general production decline from older established fields.

According to DTI statistics, the

The Buzzard Field, found in June 2001, is estimated to contain 400 million barrels of oil equivalent reserves and represents the largest oil field discovered in the

However, we are puzzled by the DTI view that the Buzzard Field will sustain the

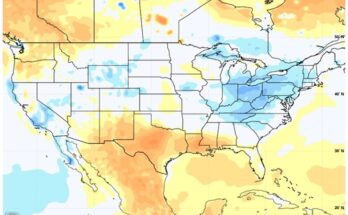

Exhibit 4. Depletion The Best Kept Secret

Source: DTI, PPHB

FERC Rule on Pipeline ROE Scares Industry

In our September 19, 2006, issue of Musings, we discussed the determination by a Federal Energy Regulatory Commission’s (FERC) administrative law judge (ALJ) that the “just and reasonable” rate of return on equity (ROE) for the Kern River pipeline project was 9.34%.

The Interstate Natural Gas Association of America (INGAA) commissioned a white paper to examine why FERC arrived at this low of a rate. It appears that when FERC is using its discounted cash flow analysis, it adds the dividend yield rate for a series of proxy companies to a projected rate of growth in earnings per share for each company. FERC then typically establishes its target ROE at the median for the range of the proxy companies. The INGAA white paper found that the selection of proxy companies was skewed due to the inclusion of companies with either local distribution or exploration and production businesses. The other companies included were more typical of pipeline companies, but two of the three companies are still recovering from their prior disastrous business expansion ventures. The white paper argued that FERC should have included some master limited partnerships (MLPs) as proxy companies because their businesses and competitive issues are similar.

FERC doesn’t include natural gas MLPs in their determination because part of their return to investors is a return of capital, which it believes is not comparable to stock dividends and might skew investor expectations. FERC recently ruled on the

The pipeline industry is upset with the FERC ruling, not just because it reduced the current Kern River ROE, but because it may impact the ability of MLPs to continue to grow their cash flows that have made their equity and debt attractive investments for investors. The high guaranteed ROE’s of MLPs have been critical for their cash flows. If increases in regulated rates are about to slow down, or even decline, this could have a significant impact on the ability of MLPs to attract investment and to continue to pay out substantial dividends. The

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.