- Growing the Offshore Fleet: Are SPACs the Answer?

- Natural Gas Market Starts To Repeat Last Year’s Pattern

- Pennsylvania Warns About Truck Traffic

- Is Paying Shareholders Dividends a Dinosaur Strategy?

- CFL Bulbs May Not Be The Savior Everyone Thinks

Note: Musings from the Oil Patch reflects an eclectic collection of stories and analyses dealing with issues and developments within the energy industry that I feel have potentially significant implications for executives operating oilfield service companies. The newsletter currently anticipates a semi-monthly publishing schedule, but periodically the event and news flow may dictate a more frequent schedule. As always, I welcome your comments and observations. Allen Brooks

Growing the Offshore Fleet: Are SPACs the Answer?

The offshore drilling rig fleet is in the midst of a major growth phase, largely driven by what appears to be an insatiable demand by international oil companies, national oil companies and other participants to drill and develop prospective offshore oil and gas reserves. This customer demand has attracted many non-traditional investors – foreign startup drilling ventures and international maritime investors – to jump into the offshore drilling business.

The traditional U.S.-based offshore drillers have taken a decidedly more conservative stance regarding their future rig fleet growth as the managements worry about Wall Street’s demand for returns on the huge capital commitments made during the past few years before encouraging another wave of capital spending. With growing rig demand still lifting leading edge day rates for offshore drillers, investors remain focused on which drillers can demonstrate profit margin improvement and/or can show that they have significant upside financial leverage (accelerating earnings growth) ahead.

The larger offshore drilling companies are beginning to struggle with how to demonstrate those characteristics. The recent Transocean/GlobalSantaFe (RIG-NYSE, GSF-NYSE) merger agreement and recapitalization program has temporarily met that requirement as shareholders can look forward to a significant cash payout through the repurchase of a large block of stock, and to a more leveraged balance sheet supported by long-term contracts on rigs in the fleet. The future use of cash to repurchase shares and reduce debt should help boost what would otherwise have become a modest growth rate for earnings per share.

With the explosion of global private equity funds over the past few years, and the publicity of the returns these funds have returned to their investors, more people have become intrigued with how they can obtain these superior investment returns and diversify their portfolios with an asset class that supposedly is non-correlated with the overall stock market. For most individuals, however, investing in private equity funds is prohibitive due to the amount of funds that one must commit and the long lockup period for the funds since the prospect of returns is years in the future. To tap this potential pool of capital, several of the very largest private equity firms, KKR and Blackstone, for example, have elected to go public and list on major stock exchanges. Now these private equity firms can raise money at any time through the sale of public stock, yet the new shareholders have no more influence on the operation of these firms as the large institutions that were invested in the funds. This is the best of both worlds for private equity managers.

Another way to participate in the private equity business, without committing millions, is to buy shares in specified purpose acquisition companies, or SPACs. These are legally referred to as “blank-check” or “blind pool” companies. SPACs sell stock to the public to raise money to invest in a particular industry segment, but without having arranged any investment before the initial public offering (IPO). In essence, investors are picking a jockey before they know what horse he will ride in an upcoming race, assuming he even finds both an attractive horse to ride and a race to run.

SPACs have become more popular in recent years as alternatives to private equity or venture capital funds. In the

Just what is a SPAC and how does it differ from a traditional private equity or venture capital investment fund? A SPAC is essentially a management team that raises cash from institutional investors in an IPO and then seeks out a transaction with a viable operating company within the targeted industry sector and within a specified time period, usually 18-24 months.

What separates SPACs from traditional blind pool investments is a set of investor safeguards – the most prominent being that the investors must vote on the acquisition and they can redeem a portion of their proceeds held in the SPAC’s trust account if they vote against the deal. Additional protections require the trust account to be liquidated if no transaction is approved within the required time frame, and without any funds going to management. Any transaction must be equal to 80% of the value of the SPAC to prevent a management team from making a small acquisition merely to keep the fund alive. Also, under SPACs, management is not paid a salary as opposed to private equity where they receive a percentage of the funds under management.

For institutional investors, the attraction of SPACs over private equity or venture capital funds is that they provide immediate liquidity since the shares trade on a public stock market; there is no discretion over the type of investment that can be made; investment downside is limited by the trust feature and liquidation time frame; management and investor interests are better aligned; and there is transparency due to public company reporting requirements. Target companies find that SPACs provide them the option of taking stock versus cash and thus avoiding the tax consequences of a sale to a private equity entity; they become a public company immediately and can avoid the IPO process and delays; and current management stands a better chance of running the new company than selling to a competitor.

The recently announced agreement to move forward on a plan of merger between privately-owned Multi-Shot LLC and JK Acquisition Corp. (JKA-AMEX) represents one such SPAC deal that fits most of the parameters outlined above. Multi-Shot, a company providing directional drilling services with an established presence in most major producing onshore oil and gas basins in the United States, is growing very rapidly. It will become publicly traded with current shareholders owning almost 61% of the new company, which will have cash available to fund Multi-Shot’s future growth. The investors are happy as demonstrated by the rise in the share price following the initial disclosure of the transaction, and they can now look forward to the company’s participation in the future growth of oil and gas exploration and development in the

Maybe the more intriguing SPAC at the present time is Paul Bragg’s Vantage Energy Services, Inc. (VTG-AMEX) that recently announced an agreement to acquire the offshore drilling rig assets of Offshore Group Investments Limited (OGIL). Vantage is acquiring four ultra-premium 375-ft. rated water depth Baker Marine design jackup drilling rigs currently under construction in

In early 2010, Vantage will become a fully established, albeit small, offshore drilling company with a fleet of the most modern, large jackup drilling rigs that have yet to be contracted in the midst of an extended period of market strength. Mr. Bragg indicated on an investor conference call that Vantage will be looking at other transactions once they close the OGIL deal, expected by early 2008.

Despite paying top dollar for the new rigs, a point that Mr. Bragg acknowledged, Vantage will benefit from owning rigs already under construction because each rig will be delivered a full year ahead of when it would otherwise have been delivered had Vantage merely placed orders for rigs at the shipyard. Four years of early cash flow in a capital intensive business is not a bad thing since it boosts returns and accelerates the timing of becoming a “real” company. But it is always important to remember that the timing of capital investments in a capital-intensive business is critical to achieving respectable returns on investment.

Importantly for investors, Vantage has struck a deal with OGIL whose owner is TMT, a global shipping company headquartered in the Far East that has previously participated in a successful SPAC (Star Maritime, SEA-AMEX), and who is also determined to make this offshore rig venture a success. What we found particularly interesting about this transaction is reflecting on how it may fit into the puzzle of how to finance the expansion of the global offshore drilling rig fleet.

From its founding in 1949, the offshore drilling business grew in a very conservative manner until the latter half of the 1970s. Up until then, outside of the brief period in the late 1960s when the domestic offshore industry was shut down following the

In Europe, speculative money in maritime countries such as

During this wave of corporate development, there were 14 limited partnership offshore drilling companies created that financed the construction of 47 drilling rigs, or 15% of all the rigs built between 1978 and 1982. Since the limited partnerships built only jackups, they accounted for 18% of that segment’s newbuild rigs. Additionally, several established offshore drilling companies such as Marine Drilling and Penrod Drilling (part of the Hunt family empire) used private limited partnerships to build rigs for their fleets.

Exhibit 1. Limited Partnerships Formed in Late 1970s

|

Rig Owner |

No. of Rigs |

|

|

|

|

Baily-Shannon |

2 |

|

Bonito Offshore |

2 |

|

Broughton Drilling |

2 |

|

|

4 |

|

Griffin-Alexander |

6 |

|

|

5 |

|

Houtech Energy |

3 |

|

Huthnance Drilling |

3 |

|

Keyes Offshore |

6 |

|

Magnum Marine |

4 |

|

Nordrill |

4 |

|

|

2 |

|

Savage Drilling |

1 |

|

|

3 |

|

|

47 |

Source: ODS, Lehman Bros., PPHB

Unfortunately, as those of us who have been around for a long time remember, the limited partnership effort ended in flames following the dip in oil prices in 1983 and their crash in 1985. As low oil prices curtailed offshore drilling and oil companies cancelled drilling contracts, these new entrant companies seemed to suffer the most since they were created for a boom and not normal times. After a multitude of bankruptcies, the partnership rigs were claimed by their bankers who then unloaded them to established contractors, both domestic and international. Many of these partnership rigs are still in the fleets of offshore drilling companies today.

While limited partnership rigs were not the driving force in the expansion of the offshore drilling rig fleet in the late 70’s and early 80’s, they did add incremental capacity to the industry that impacted the pace of the recovery from the industry depression of the second half of the 1980s. During the boom, Global Marine Drilling, headed by Russell Luigs, emerged as one of the most aggressive new rig builders. By utilizing cheap financing from foreign governments,

designed to secure work for their shipyards, and low-cost subsidized financing from the U.S. Maritime Administration, Global Marine was able to build rigs at a very rapid pace. In the aftermath of the industry collapse, Mr. Luigs noted that the mistake he made was not building more rigs and soaking up all the shipyard capacity because then he would have controlled the rig market. While probably spoken in jest, Mr. Luigs’ comment reflected a prevailing attitude in those days – there was nothing that could derail this growing offshore drilling rig market.

Exhibit 2. History of Rig Fleet Growth – Jackups and Ships

Source: ODS, Lehman Bros., PPHB

When we look at the offshore drilling industry’s current newbuilding effort, we are struck by the minimal participation by the established U.S.-based drilling contractors. Only 35 of the 144 offshore drilling rigs, either currently on order or that have been delivered in 2007, are owned by established U.S.- or European-based contractors. This is only 24% of the newbuilding program. Only 20 of the newbuilding rigs will be owned by U.S.-based contractors, or less than 14% of the total.

Capital seems to have been more easily raised by non-U.S. offshore drilling entities in stock markets in

Natural Gas Market Starts To Repeat Last Year’s Pattern

The North American natural gas market outlook has been weak, but it seems to be strengthening as industry actions suggest the possibility of a repeat of last year’s price recovery pattern. At the end of last year’s summer season, the natural gas market was oversupplied (gas in storage hit the magic 3TCF level by early September) due to reduced consumption caused by a warm 2005-2006 winter and a mild 2006 summer.

On the supply side, natural gas imports from

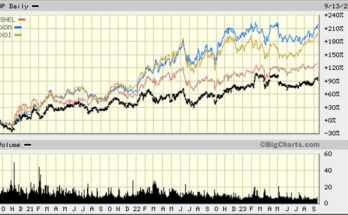

Exhibit 3. Natural Gas Prices Have Remained Flat Since Katrina

Source: NYMEX, EIA, PPHB

Source: NYMEX, EIA, PPHB

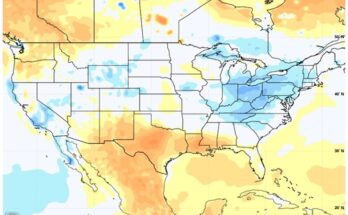

This year appears to be repeating the pattern of last year as we experienced a milder winter and in many parts of the country (those where populations are greater), a cooler summer. Through the first half of this year, gas imports from

Exhibit 4. Canadian Gas Down and LNG Imports Up In 2007

Source: EIA. PPHB

Natural gas in storage at September 7, 2007, passed the 3TCF level, just as it had at the same time last year, and storage volumes will go higher before the start of the withdrawal season. The absence of demand as a result of mild summer weather, coupled with stable Canadian gas imports and a huge increase in LNG imports, explains why gas storage volumes are up. The key question is whether these trends continue or should we expect some changes in the future?

Exhibit 5. 2007 Storage At Top Of 5-Year Range

Source: EIA

Last year, as gas storage volumes climbed above 3 TCF, natural gas prices began to collapse, ultimately falling to a low of $4.20 per thousand cubic feet (mcf). In response to low natural gas prices, one of the leading gas producers – Chesapeake Energy Corp. (CHK-NYSE) – announced plans to shut-in some production and slowdown its drilling activity. The day CHK announced its cut marked the gas futures bottom for 2006. Other producers followed CHK’s lead. The increased producer discipline, coupled with the early arrival of cooler weather, propelled gas prices above $8 per mcf by late November before warmer weather killed the price rally.

So why might this coming fall offer a repeat of last fall’s gas price recovery? The primary reason could be that CHK has cut its production again and is slowing down its drilling effort. CHK’s CEO Aubrey McClendon, in a conference call with investors to discuss the corporate strategy move, said that it was taking these steps because it has been “too successful” in growing production. According to Mr. McClendon, CHK’s gas production growth has been responsible for 50% of the country’s 1 BCF of surplus gas in the system today. As a result, at today’s natural gas prices, Mr. McClendon believes the entire industry is uneconomic unless producers have hedged a substantial volume of their production at higher prices.

He began his conference call by saying that the natural gas market today is remarkably similar to the market 11 months ago. While CHK is cutting 200 million cubic feet per day (mmcf/d) of gross production versus its 150 mmcf/d cut last year, Mr. McClendon isn’t sure there will be an exact repeat of the price recovery of last year, but he also didn’t think the market would see $4-5 per mcf gas prices this fall. He further went on to discuss the natural gas storage market. Since gas demand continues to grow and supplies are coming from many more places than in the past, Mr. McClendon believes that gas storage capacity has grown by 200-350 BCF in each of the last two years. This storage growth is in step with demand growth of roughly 100 BCF a year. Therefore, he believes investors should be using 3.6 TCF as the threshold volume before becoming concerned about excess gas storage rather than the traditional 3 TCF benchmark used for many years. By that measure, the market should not be concerned about the fact that there is 3 TCF of gas in storage at the beginning of September.

Exhibit 6. Natural Gas Prices Rallying; Repeat of 2006?

Source: NYMEX, EIA, PPHB

As shown in Exhibit 6, with the help of the production cuts and a Gulf of

Pennsylvania

On our recent drive home from

Another explanation may be that states are beginning to run out of road projects to do. Quite possibly the states are running out of money to build and repair roads, or maybe the states are not getting as much money from Washington, which they must match, for projects to go forward. However, the lack of road construction made the drive easier, although there was still a large volume of truck traffic.

We were also struck by the recognition of the increased truck traffic phenomenon, at least by the State of

Truck stops provided an interesting scene. At night, all the public rest stops and the commercial truck stops that we could see from the highway were aglow with red, yellow and blue lights that illuminate trucks and their rigs. Just before we left for

The revised rules for truck driver safety mandate they drive no more than 11 hours in a 14-hour work day, thus truck drivers must stop for a 10-hour rest period. It is the combination of the new work rules and the growth of truck traffic (FHA estimates 2.7% annual truck traffic growth) that has created these overcrowded rest stops, especially at night. In some cases, trucks are parking on the entrance and exit ramps at overcrowded rest stops making for dangerous conditions for all vehicles entering or exiting. The FHA suggests that one way to address this situation is to improve the knowledge of truckers about the status of parking facilities at both public and commercial sites, but this will require that technology be employed such as GPS systems, radio broadcasts or electronic signs that can communicate the parking information. Building new rest stops does not appear to be a solution given the problem with our bridges and road infrastructure.

Our last observation about trucks was that we didn’t notice as many belching black soot out of their exhaust stacks. Other than the occasional truck – and most of them were construction vehicles – almost all the trucks we saw had clean exhausts. Is that a function of the new, low-sulfur diesel, or is it tied to the heavy investment trucking companies have made in recent years in new tractors in advance of the new emissions rules? Whatever the reason, it was a noticeable change over the past few years.

The last interesting thing we noticed was how different states word their traffic signs. It seems some states are able to say the same thing in fewer words than other states. The best example is the signs deployed before bridges warning drivers about ice forming on them in bad weather. From “Bridge May Be Icy” to “Ice May Form on Bridge During Bad Weather,” certain states are challenging drivers to become speed readers. One would think that since all traffic signs are standardized across the country, states could try to agree on the least number of words to convey warnings about potential traffic issues.

Is Paying Shareholders Dividends a Dinosaur Strategy?

There is a new analysis of the changing strategy for how Corporate America rewards its shareholders. The study was done by Douglas J. Skinner, the John P. And Lillian A. Gould Professor of Accounting at the University of Chicago Graduate School of Business, and will be published in the upcoming issue of the Journal of Financial Economics. Dr. Skinner’s research was designed to examine the thesis that stock repurchases are being substituted for dividends as the preferred method for returning profits to shareholders due to the increased volatility of corporate earnings.

The research builds on a long line of academic research into the issue of dividends and stock repurchases that began with the work of

Dr. Skinner begins his analysis by showing that since 1980 there are three groups of companies with discernible strategies. First are the established firms that have always paid dividends and now also make repurchases on a regular basis. Second are the firms that make regular repurchases but do not pay dividends. Last are the firms that make occasional repurchases.

The first group of companies has been paying dividends for decades and continues to do so largely because of their dividend history. Over the years, the managers of these companies have increasingly used repurchases to pay out earnings increases with dividends being either maintained or increased very slowly. This pattern suggests to Dr. Skinner that the reluctance to reduce or omit dividends has become stronger over the years. This group of companies dominates the set of publicly-held firms and they account for more than half of all total earnings and dividends paid. These results suggest repurchases are being used increasingly in place of regular dividend hikes.

According to the report on the research, Dr. Skinner makes all the arguments for why dividends are less favored by corporate managers: 1) they represent a significant ongoing commitment by the firm; 2) reducing or omitting dividends sends a very negative message to the investment community; and 3) dividends are taxed at regular income tax rates, as opposed to gains from stock repurchases that are taxed at the lower capital gains tax rate. The last reason has been weakened in recent years by the change in

The primary contribution of Dr. Skinner’s research is to study the substitution hypothesis that stock repurchases are actually being used as substitutes for dividends. If that is the case, then stock repurchases should be linked to earnings because prior financial research has shown that managers set dividends based on current and past earnings.

Dr. Skinner finds that the relationship between dividends and earnings has become weaker in recent decades, largely because managers now set dividends in a mechanical fashion with small, predictable increases. At the same time, the relation between earnings and repurchases has become stronger, suggesting that managers are increasingly using repurchases to pay out earnings increases. To test this hypothesis, Dr. Skinner used information on earnings, dividends and net repurchases for publicly held

Further support for his hypothesis is the trend in the proportion of dividend paying companies, which peaked in the late 1970s at around 66%. That proportion declined to 42% in the 1980-1989 timeframe and further fell to 28% in 1995-2004. Dr. Skinner examined the dividend paying record of companies to help understand today’s repurchase decision-making. He looked at the number of years before 1980 that companies had paid dividends. He concluded that most companies that continue to pay dividends today have paid dividends for many decades; companies that make regular share repurchases but do not pay dividends have little or no dividend history; and few newer companies initiate dividends. He also found that for companies that have never paid dividends but make regular repurchases, there is an increasingly strong relation between earnings and repurchases, which suggests that these companies are using repurchases in place of dividends.

The most interesting conclusion from Dr. Skinner’s research is that while managers use share repurchases to offset the dilutive effect of stock option programs and to increase earnings per share, this only explains the timing of repurchases. The level of repurchases is driven by earnings. Because the data shows clearly that the number of companies that only pay dividends has shrunk between 1980 and 2005 from 13% to 7% of Corporate America, and these are largely the domain of a small group of large, well-established “blue chip” companies, Dr. Skinner believes dividends days are numbered.

While we have not had the opportunity to read the entire research report, we wonder how much the change in CEO compensation plays in the increased interest in share repurchases, which are designed to boost earnings per share growth and push stock prices higher. After the 1993 change in CEO salary deductibility for tax purposes (capped at $1 million) and the resulting shift in favor of incentive compensation plans, boosting a company’s share price becomes an excellent way to provide more money to top management. Adding to this factor has been the explosive growth in institutional and hedge fund money in the market place that has increased the pressure on company managements to generate near-term stock price performance.

Call us old-fashioned, or maybe just old, but dividends to us provide a stream of income that can only be replicated by actually selling shares of non-dividend paying companies. We find that our family and friends are much more in love with dividend paying stocks than the others, even though they understand the fact that non-dividend payers are often faster growing companies. An aging population will be looking increasingly toward income streams not dependent on the government. We think Dr. Skinner’s predicting the eventual end of dividends is quite premature.

CFL Bulbs May Not Be The Savior Everyone Thinks

In a world focused on both cutting energy use and reducing emissions, the compact fluorescent light bulb (CFL) has been deemed the easiest and best solution for the mission. This solution has reached a level of acceptance that several states (

The growing pressure to ban the sale of incandescent light bulbs has forced the U.S. Congress to consider the issue, if for no other reason than to establish a national unified standard. This pressure often evolves from manufacturers’ demands in order to not have to develop separate products for each state. The legislation being worked on by the House and Senate would phase out incandescent light bulbs in steps beginning in 2012. The phase-out would begin with 100-watt bulbs and then 75-watt bulbs a year later and then the 60- and 40-watt bulbs by 2014. The bulbs would be replaced by either CFL bulbs or more-efficient incandescent lamps. By 2020, the

Exhibit 7. Tungsten Filament Creates Heat and Light

Source: HowStuffWorks.com

An incandescent light bulb is made with a thin tungsten filament inside a glass sphere, a design that Thomas Edison worked on until he had a light bulb that burned for 1,300 hours. The electricity flows through a filament, which offers significant resistance and generates heat. The heat turns the filament white hot, which is the light. However, there is a substantial amount of heat that is lost because it is not light. On the other hand, a fluorescent bulb has a stream of electrons flowing between the electrodes at each end of the bulb. The electrons interact with mercury vapor atoms floating inside the bulbs. The mercury atoms become excited and as they return to an unexcited state they release photons of light in the ultraviolet region of the spectrum. The atoms collide with the phosphor coating inside the bulb and create visible light.

Exhibit 8. Inciting Atoms Key to CLF Light Output

Source: HowStuffWorks.com

In an attempt to conserve electricity and reduce our carbon footprint, we have been gradually substituting CFL bulbs for incandescent bulbs in our home. Unfortunately, we have been frustrated by the number of CFL bulbs that burned out in a reasonably short time, given the marketing pitch that these bulbs should last for years. We know CFL bulbs cannot be used with dimmer switches and in wet locations, but we have not put the bulbs in those situations. As we wrote in a previous article on CFL bulbs, we found significant differences in bulb selection among the major retailers and between stores within the same retail chain, but in different regions of the country. Our conclusion is that individual stores or different geographic regions have their own product specifications rather than having a corporate-wide standard, but bulb selections are growing.

Because of our experience with failing CFL bulbs, we actually switched back to an incandescent bulb in one particular light in our house. Given our frustration with the CFL bulb performance, we were very interested in an article detailing the use of CFL versus incandescent light bulbs in restaurants in northern

There seemed to be a significant difference in understanding exactly how the manufacturer claims about the life of CFL bulbs are determined. One expert claimed that “the lifespan of a CFL is based on CONTINUOUS operation. They are not intended (like all fluorescent products) to be turned on and turned off like an incandescent light bulb.” Based on this reader’s comments, his experiment with CFLs has been a “financial wipeout” with a negligible impact on his electricity bill. His recommendation was to keep using your existing light bulbs and turn off lights when no one is in the room, i.e. conservation.

An energy consultant responded to the initial question with a report on a study he had started two years ago. He wanted to see what impact there was on the life of CFL bulbs by switching them on and off. He described the test facility he created, but the bottom line was that the first bulb he tested burned out after slightly more than a year, or after about 4,500 hours of operation and 9,000 cycles. The next bulb lasted about three months longer, or about 5,600 hours and 11,000 cycles. The other two bulbs he tested are still burning. His conclusion is that in the real world, CFL bulbs won’t last as long as claimed, but they last quite a bit longer than incandescent light bulbs.

Numerous other readers claimed that their experience suggested that CFL bulbs didn’t last as long as claimed by the manufacturers and the best solution was to conserve electricity by turning off lights. Some others said they were waiting for light emitting diodes (LEDs) to become more powerful and lower in cost, as they believe this technology will supplant CFL bulbs.

Another reader, a lighting specialist for a large utility commented that the lifespan of CFL bulbs is not rated on continuous use, but rather on their performance over cycles. He said they are tested on three-hour cycles of ON and then OFF for several minutes and then ON again until 50% of tested bulbs have failed. He commented on one

Exhibit 9. CFL Bulb Choices Are Expanding

Source: Wikipedia.org

of the toughest environments for CFL bulbs that contributed to their shorter lifespan; their use in recessed cans or totally enclosed fixtures. This seems to be the case based on our experience with CFL bulbs. The reader also talked about the CFL bulb problems with dimmers, three-way switches, and photo sensors. We have experienced failures in lights attached to photo sensors, which seems strange since the sensor only turns the light ON and then OFF. We will have to do more research to understand why photo sensor-controlled lights create operating problems for CFLs.

The best information was the last comment, in which the reader directed people to the October 2007 issue of Consumer Reports. While we haven’t read the entire article, there is a summary of it on their web site, www.ConsumerReports.org. Consumer Reports’ bottom-line was to only use Energy Star-qualified CFL bulbs. They lasted longer than incandescent light bulbs, based on a cyclical test of three hours on and twenty minutes off until they burned out. They did point out that CFL bulbs are not for every lighting application. Consumer Reports’ primary concern was the recycling problem for CFL bulbs because of the mercury they contain. The web site does have a link to a site explaining how to clean up a broken CFL bulb and other mercury spills. We have reprinted the CFL bulb cleanup steps below.

What to Do if a Fluorescent Light Bulb Breaks

Fluorescent light bulbs contain a very small amount of mercury sealed within the glass tubing. EPA recommends the following clean-up and disposal guidelines:

1. Open a window and leave the room for 15 minutes or more.

2. Carefully scoop up the fragments and powder with stiff paper or cardboard and place them in a sealed plastic bag.

· Use disposable rubber gloves, if available (i.e., do not use bare hands). Wipe the area clean with damp paper towels or disposable wet wipes and place them in the plastic bag.

· Do not use a vacuum or broom to clean up the broken bulb on hard surfaces.

3. Place all cleanup materials in a second sealed plastic bag.

· Place the first bag in a second sealed plastic bag and put it in the outdoor trash container or in another outdoor protected area for the next normal trash disposal.

Note: Some states prohibit such trash disposal and require that broken and unbroken lamps be taken to a local recycling center.

· Wash your hands after disposing of the bag.

4. If a fluorescent bulb breaks on a rug or carpet:

· First, remove all materials you can without using a vacuum cleaner, following the steps above. Sticky tape (such as duct tape) can be used to pick up small pieces and powder.

· If vacuuming is needed after all visible materials are removed, vacuum the area where the bulb was broken, remove the vacuum bag (or empty and wipe the canister) and put the bag or vacuum debris in two sealed plastic bags in the outdoor trash or protected outdoor location for normal disposal.

If you don’t want to deal with all these steps, your alternative is to call a hazardous waste cleanup company as a lady we wrote about previously had to do, only to be presented with a bill for $2,000. Based on the real world, CFL bulbs have substantial benefits, but outlawing incandescent bulbs, as the U.S. Congress is contemplating doing, will merely put citizens in a difficult situation given the fact CFL bulbs are not directly interchangeable with all incandescent bulbs. Think any politician will care about that inconvenient fact when they vote?

Contact PPHB:

1900 St. James Place, Suite 125

Houston, Texas 77056

Main Tel: (713) 621-8100

Main Fax: (713) 621-8166

www.pphb.com

Parks Paton Hoepfl & Brown is an independent investment banking firm providing financial advisory services, including merger and acquisition and capital raising assistance, exclusively to clients in the energy service industry.